High-toughness hot-formed steel with tensile strength higher than or equal to 1800 MPa grade and production method thereof

A technology of tensile strength and hot-formed steel, applied in the field of metallurgy, can solve the problems of low toughness and cold-bending performance, and achieve the effects of improving toughness and cold-bending performance, uniform distribution of tissue components, and improving cold-bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

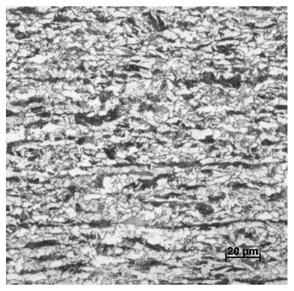

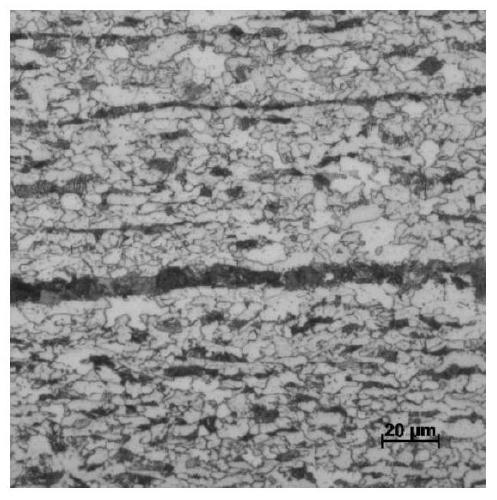

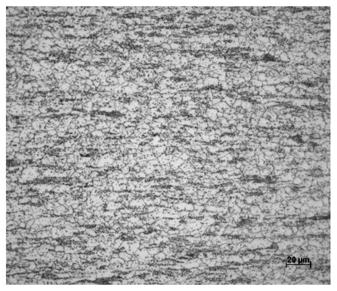

Image

Examples

Embodiment 1

[0055] A high-toughness hot-formed steel with a tensile strength ≥ 1800 MPa grade of the present invention, the mass percentage of each component is: C0.29-0.35%, Si≤0.5%, Mn 0.5-1.5%, P≤0.020%, S≤ 0.010%, Cr≤0.50%, Al 0.01~0.06%, Nb 0.01~0.06%, V 0.01~0.06%, Mo≤0.5%, and the rest are Fe and unavoidable impurities.

[0056] The production process is as follows:

[0057] 1. Smelting;

[0058] 2. Cast billet;

[0059] 3. Hot rolling: Hot rolling is carried out on the cast slab, wherein the temperature of exiting the furnace is 1000-1250°C, the temperature of final rolling is 850-900°C, and the temperature of coiling is 500-600°C;

[0060] 4. Cold rolling: Pickling the hot-rolled product, and then continuous cold rolling, wherein the cold rolling reduction is ≥50%;

[0061] 5. Annealing: continuous annealing is carried out on the cold-rolled product, and the annealing temperature is 700-820°C;

[0062] 6. Thermoforming: After annealing, the product is subjected to hot stampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com