X70 pipeline steel hot rolled coil and manufacture method thereof

A manufacturing method and hot-rolled coil technology are applied in the field of X70 pipeline steel hot-rolled coil and its manufacturing, which can solve the problem of not being able to have both HIC resistance and SSCC resistance at the same time, and achieve the effect of good hydrogen sulfide corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

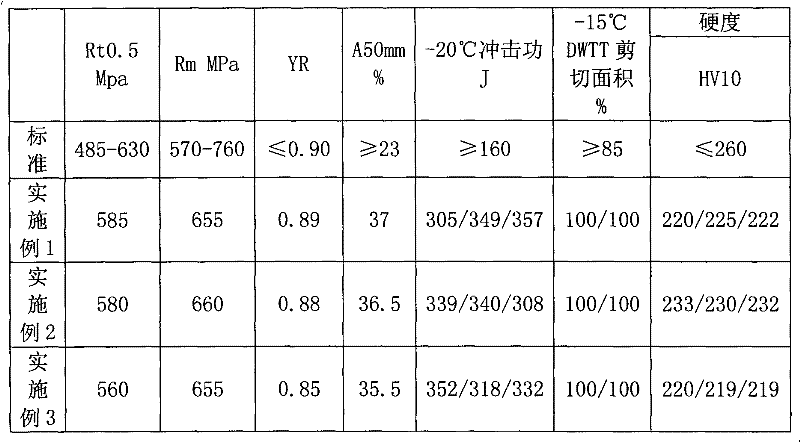

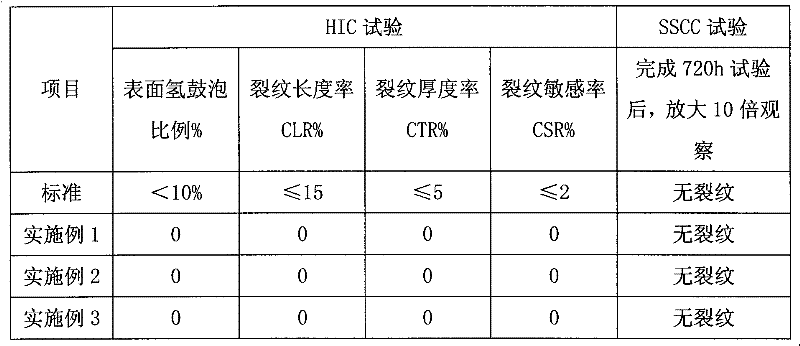

Examples

Embodiment Construction

[0085] The specific implementation of the present invention will be further described below in conjunction with the examples, but the specific implementation of the present invention is not limited to the following examples.

[0086] Manufacturing method embodiment one

[0087] This embodiment is carried out on the top-bottom re-blowing converter and the hot continuous rolling mill, and the process route adopted is:

[0088] Hot metal pretreatment→converter smelting→LF refining outside the furnace→RH refining outside the furnace→slab continuous casting→slab heating→high pressure water descaling→rough rolling unit rolling→finishing high pressure water descaling→finish rolling unit rolling→ Laminar cooling → coiling.

[0089] This embodiment is the following sequential steps:

[0090] I hot metal pretreatment

[0091] S (percentage by weight) in molten iron is removed to 0.003%;

[0092] II converter smelting

[0093] Add 173 tons of pre-treated molten iron conforming to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com