Steel for 36kg-grade ocean platform and production method thereof

A technology for offshore platforms and production methods, which is applied to steel for offshore platforms, 36kg-grade steel for offshore platforms and its production fields. It can solve problems such as uneven water cooling, narrow process window, and difficult production, and achieve good cold bending performance, The effect of uniform comprehensive performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

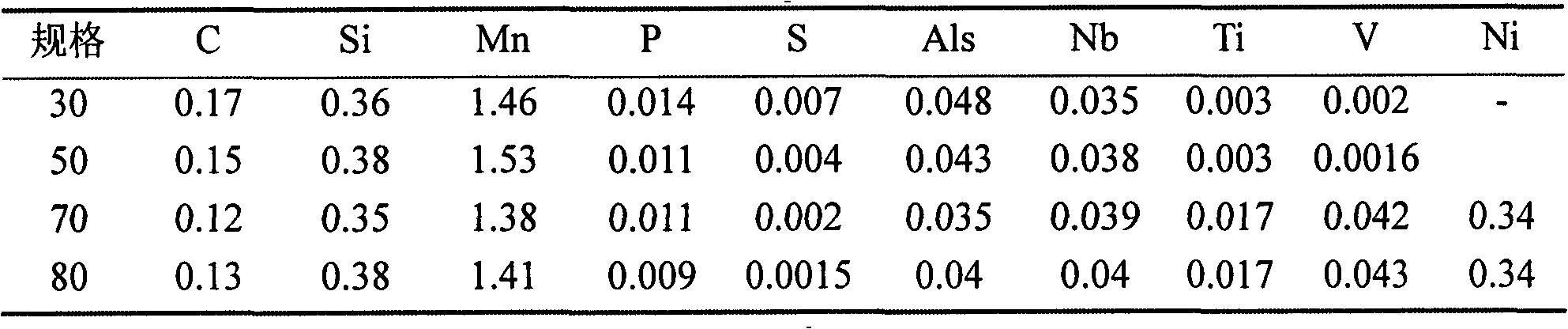

[0019] According to the chemical composition ranges of schemes 1 and 2 provided by the present invention, according to the above-mentioned technological process, smelt 250mm×2000mm×L continuous casting slabs on a 100-ton converter, and roll 30, 50, 70, and 80mm respectively on a 4300mm wide and thick plate rolling mill The chemical composition of the steel plate is shown in Table 1, the parameters of rolling and normalizing process are shown in Table 2 and Table 3, and the properties are shown in Table 4.

[0020] The chemical composition (weight, %) of the trial production steel plate of table 1

[0021]

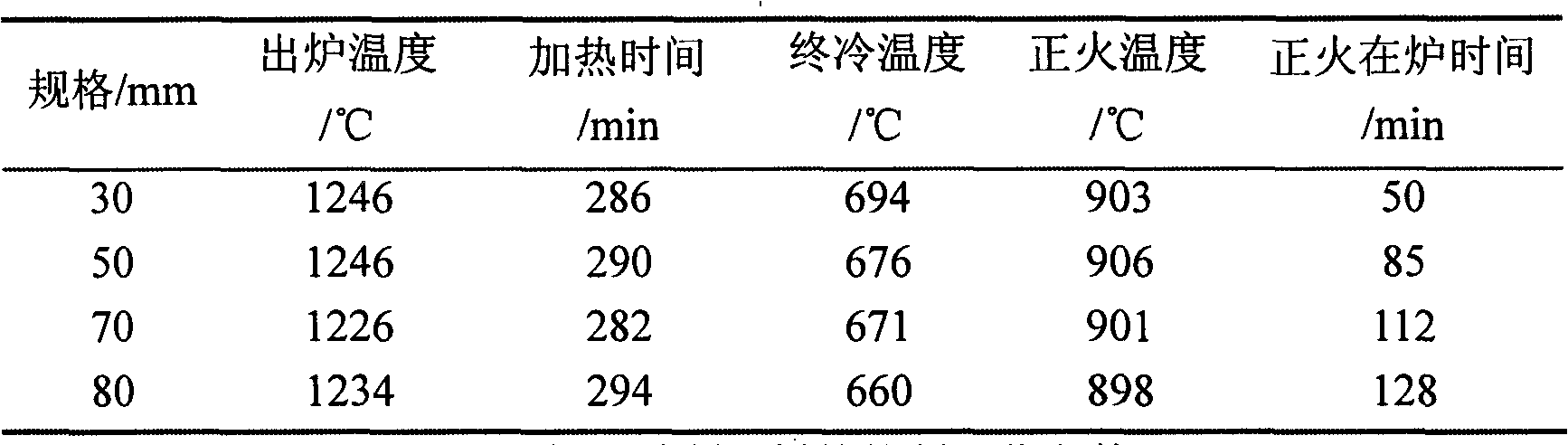

[0022] Table 2 Heating, water cooling and normalizing process parameters of the trial steel plate

[0023]

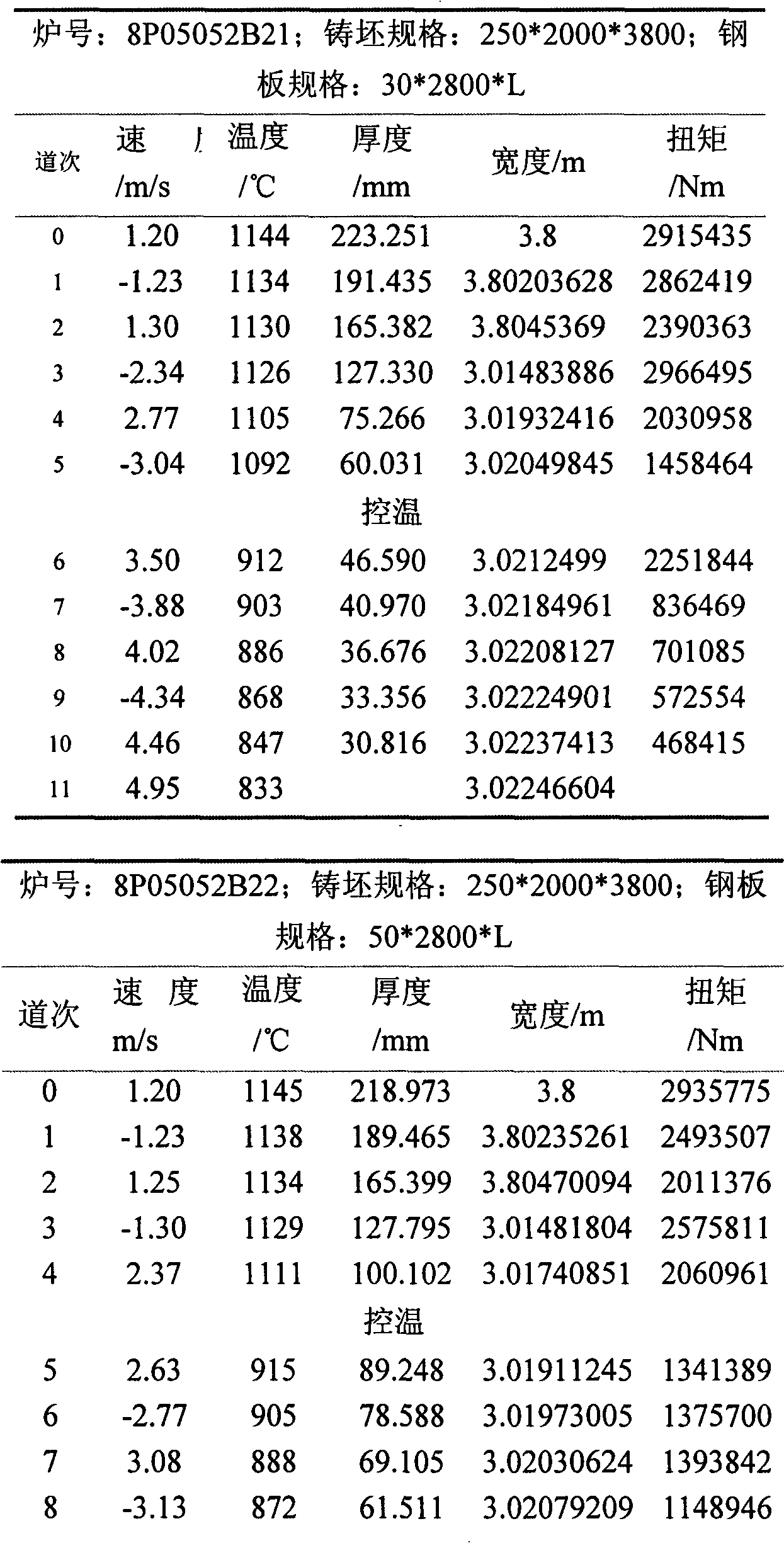

[0024] Table 3 The rolling process parameters of the trial steel plate

[0025]

[0026]

[0027] Table 4 Mechanical properties of trial-produced steel plates

[0028]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com