High-strength automobile axle housing material and method for manufacturing axle housing

A manufacturing method and high-strength technology, which are applied in the field of automobile axle housings to achieve the effects of good welding performance, reduced weight and high material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-strength automobile axle housing material, the chemical composition of the automobile axle housing material is: C 0.16%, Si 0.39%, Mn 1.53%, P 0.015%, S 0.003%, Ti 0.026%, V 0.026% , Nb 0.059%, Cr 0.08%, Ni 0.05%, Cu 0.02%, Alt 0.029%, and the balance is Fe. The thickness of the steel plate used in the axle housing is 14mm.

[0031] A method for manufacturing a high-strength automobile axle housing, comprising the following steps:

[0032] 1) Steel plate cutting: cutting the hot-rolled steel plate with the above composition;

[0033] 2) Steel plate heating: use KGPS02 medium frequency induction heating furnace (rated output voltage 700V, maximum input current 680A, rated output frequency 3000HZ, rated output power 350KW) to heat for 3-4 minutes, and the heating temperature is 870-920°C;

[0034] 3) Hot pressing of steel plate: Hot pressing is carried out on a 1000-ton press, and the holding time is 0.01s;

[0035] 4) Steel plate shaping: Then carry out shaping...

Embodiment 2

[0045]A high-strength automobile axle housing material, the chemical composition of the automobile axle housing material is: C: 0.18%, Si: 0.35%, Mn: 1.46%, P: 0.011%, S: 0.005%, Ti: 0.024%, V: 0.031%, Nb: 0.048%, Cr: 0.04%, Ni: 0.02%, Cu: 0.01%, Alt: 0.049%, and the balance is Fe. The thickness of the steel plate used in the axle housing is 14mm.

Embodiment 3

[0047] A high-strength automobile axle housing material, the chemical composition of the automobile axle housing material is: C: 0.16%, Si: 0.42%, Mn: 1.48%, P: 0.017%, S: 0.004%, Ti: 0.024%, V: 0.032%, Nb: 0.051%, Cr: 0.09%, Ni: 0.05%, Cu: 0.03%, Alt: 0.031%, and the balance is Fe. The thickness of the steel plate used in the axle housing is 14mm.

PUM

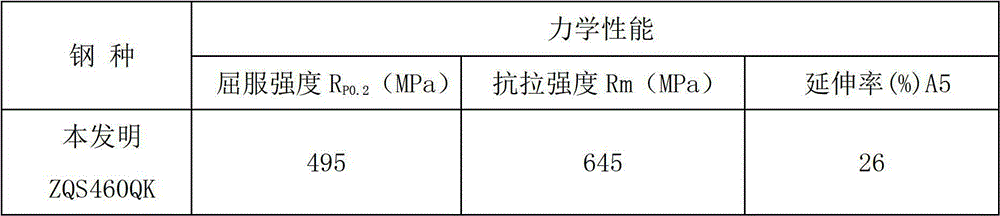

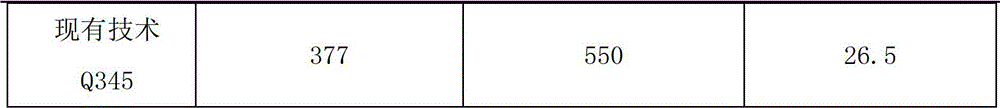

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com