Low-yield ratio, high heat input welding, high-strength and high ductility steel plate and method of manufacture

A large input energy welding, low yield ratio technology, applied in the direction of temperature control, etc., can solve the problems that cannot withstand large input energy welding, low temperature toughness can not be achieved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

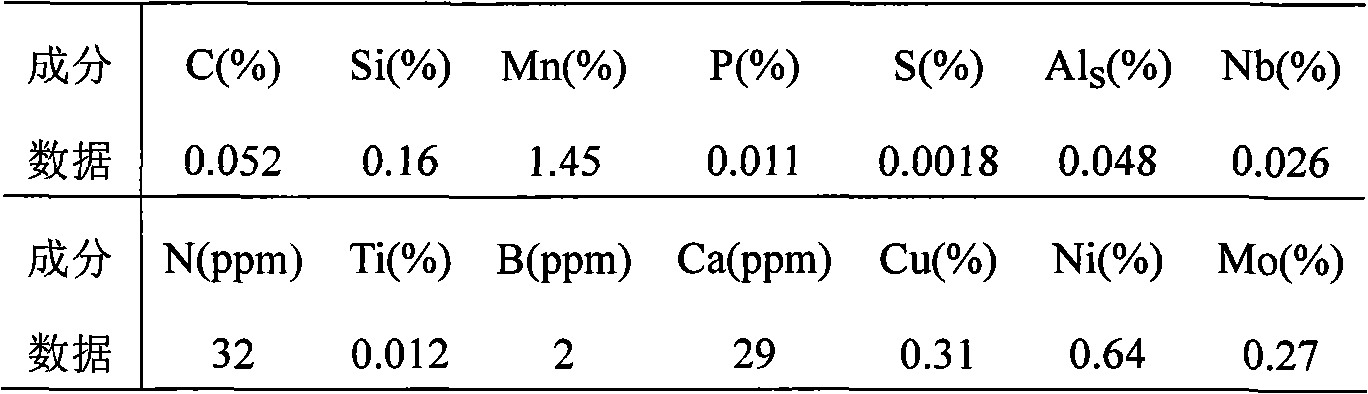

[0038] The continuous casting step was carried out according to the chemical composition shown in Table 1, and the thickness of the obtained steel plate was 30mm. Subsequently, the slab is heated at a low temperature, and the heating temperature is 1080°C. Carry out hot rolling reaction afterwards, in the rapid continuous rolling step, the pass reduction rate is 15%, and the cumulative reduction rate is 60%; in the controlled rolling step, the pass reduction rate is 11%, and the cumulative reduction rate The rate is 67%. The finish rolling temperature was 793°C. After the hot rolling reaction is finished, enter the cooling step, the transfer time is 28s, the cooling rate is 15°C / s, and the cooling stop temperature is 572°C. Steel plate properties: see Table 10.

[0039] Table 1 Chemical composition of steel plate in Example 1

[0040]

Embodiment 2

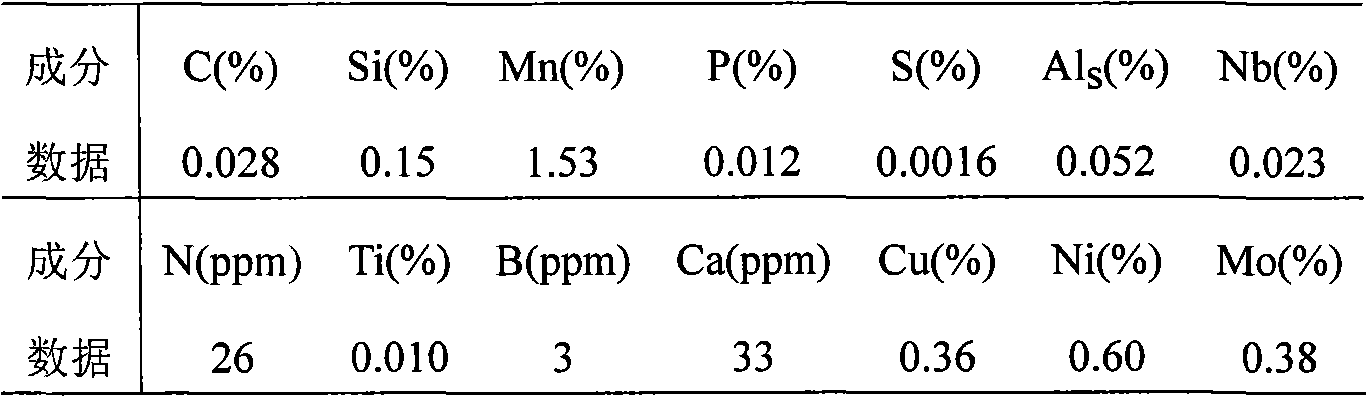

[0042] Steel sheets were manufactured with the chemical compositions shown in Table 2, and the manufacturing process was the same as in Example 1. The thickness of the steel plate is 70mm. The heating temperature of the low-temperature heating of the slab is 1110°C. In the rapid continuous rolling step, the pass reduction rate is 12%, and the cumulative reduction rate is 52%; in the controlled rolling step, the pass reduction rate is 9%, and the cumulative reduction rate is 60%. The finish rolling temperature was 765°C. The transfer time is 46s, the cooling rate is 11°C / s, and the cooling stop temperature is 476°C. Since the steel plate thickness of the newly designed steel 2 is ≥40mm, it needs to be cooled slowly to below 100°C and then naturally air-cooled to room temperature. In this embodiment, the slow cooling end temperature is 90°C. Steel plate properties: see Table 10.

[0043] The chemical composition of table 2 embodiment 2 steel plate

[0044]

Embodiment 3

[0046] Steel sheets were manufactured with the chemical compositions shown in Table 3, and the manufacturing process was the same as in Example 1. The thickness of the steel plate is 50mm. The heating temperature of the low-temperature heating of the slab is 1100°C. In the rapid continuous rolling step, the pass reduction rate is 12%, and the cumulative reduction rate is 55%; in the controlled rolling step, the pass reduction rate is 10%, and the cumulative reduction rate is 67%. The finish rolling temperature was 780°C. The transfer time is 18s, the cooling rate is 12°C / s, and the cooling stop temperature is 547°C. Since the steel plate thickness of the newly designed steel 3 is ≥40mm, it needs to be cooled slowly to below 100°C and then naturally air-cooled to room temperature. In this embodiment, the slow cooling end temperature is 95°C. Steel plate properties: see Table 10.

[0047] The chemical composition of table 3 embodiment 3 steel plate

[0048]

[0049] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com