Hot rolled weatherproof bridge steel with yield strength of 500 MPa level and manufacturing method thereof

A yield strength, bridge steel technology, applied in the field of metal materials, can solve the problems of strength and weather resistance that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 The chemical components contained in the hot-rolled weathering bridge steel with a yield strength of 500 MPa in this example are as follows: C 0.05%, Si 0.38%, Mn 1.46%, P 0.013%, S 0.0020%, Cu 0.36 %, Ni 0.33%, Cr 0.5%, Mo 0.15%, Nb 0.056%, Ti 0.021%, Al 0.023%, and the rest are Fe and unavoidable impurities.

[0036] The preparation process of the weather-resistant bridge steel in this example is as follows: the smelting raw materials are configured according to the chemical composition of the weather-resistant bridge steel, and the smelting raw materials are smelted, molten iron pre-desulfurization, converter top-bottom composite blowing, RH vacuum cycle degassing, and rare earth or Ca treatment Finally, through the whole process of protective pouring, the target billet is formed. .

[0037] After the slab is heated at 1250°C for 2 hours, two-stage rolling is carried out, in which the rough rolling start temperature is 1080°C, the cumulative rough rolling ...

Embodiment 2

[0038]Example 2 In this example, the chemical components contained in the hot-rolled weathering bridge steel with a yield strength of 500 MPa are as follows: C 0.07%, Si 0.39%, Mn 1.22%, P 0.008%, S 0.0044%, Cu 0.4%, Ni 0.3%, Cr 0.5%, Mo 0.15%, Nb 0.05%, Ti 0.02%, Al 0.03%, and the rest are Fe and unavoidable impurities.

[0039] The preparation process of the weather-resistant bridge steel in this example is as follows: the slab is made according to the same process as in Example 1, and then the slab is heated at 1250°C for 2 hours, and then two-stage rolling is carried out, wherein the rough rolling start temperature is 1100°C, the cumulative downdraft of rough rolling is 60%, the temperature of finish rolling is 940°C, the end temperature of finish rolling is 840°C, and the cumulative downdraft of finish rolling is 75%. After rolling, the rolled piece is cooled to 530°C, the cooling rate is 11°C / s, and the mechanical properties of the finished weather-resistant bridge steel...

Embodiment 1~2

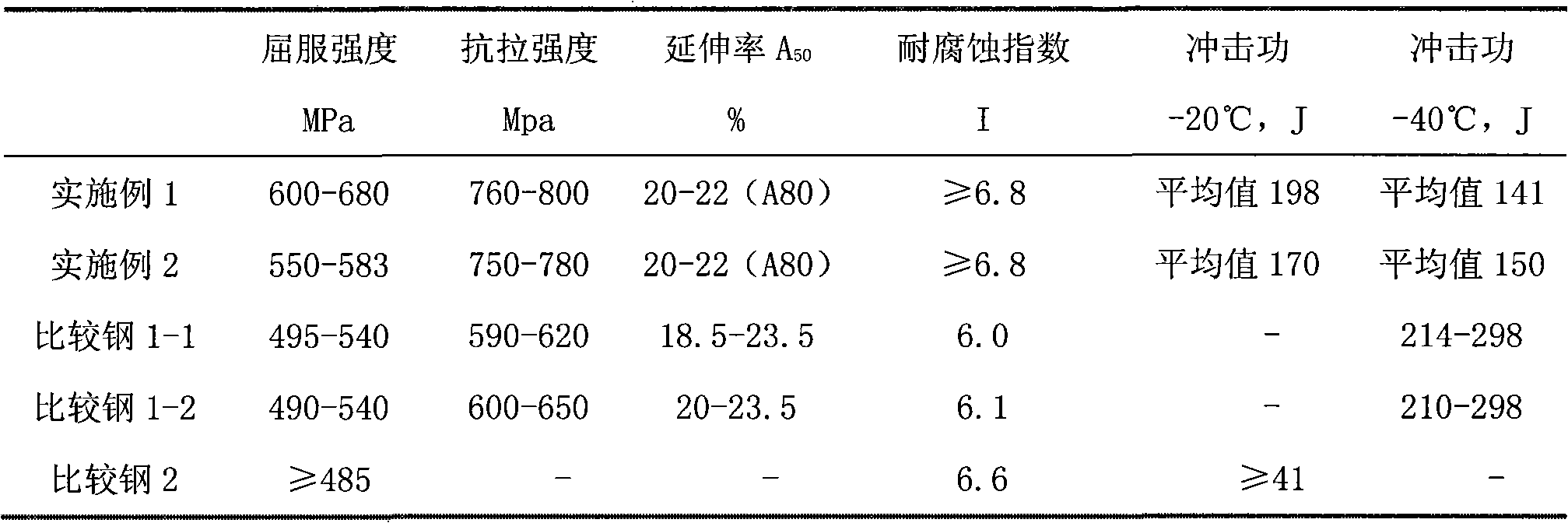

[0040] Table 1 Examples 1-2 mechanical properties

[0041]

[0042] The bridge weathering steel described in Example 1-2 of the present invention and the comparison steel 1-1 and comparison steel 1-2 proposed in the invention patent with the publication number CN1609257A and the comparison steel 2 proposed in the invention patent with the patent number US6315946 The comparison of mechanical properties and corrosion resistance is shown in Table 1. The calculation formula of the corrosion resistance index I in the table is the Legault-Leckie formula revised in the American Society for Testing and Materials standard ASTM G101-01. The higher the value, the stronger the corrosion resistance. It can be seen from the above table that compared with the comparison steel, the steel of the present invention has high strength, better impact energy at low temperature, and better corrosion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com