Three-layer composite steel plate and manufacturing method thereof

A manufacturing method and layer compounding technology, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve problems that do not involve the characteristics and comprehensive performance of steel plate products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A6

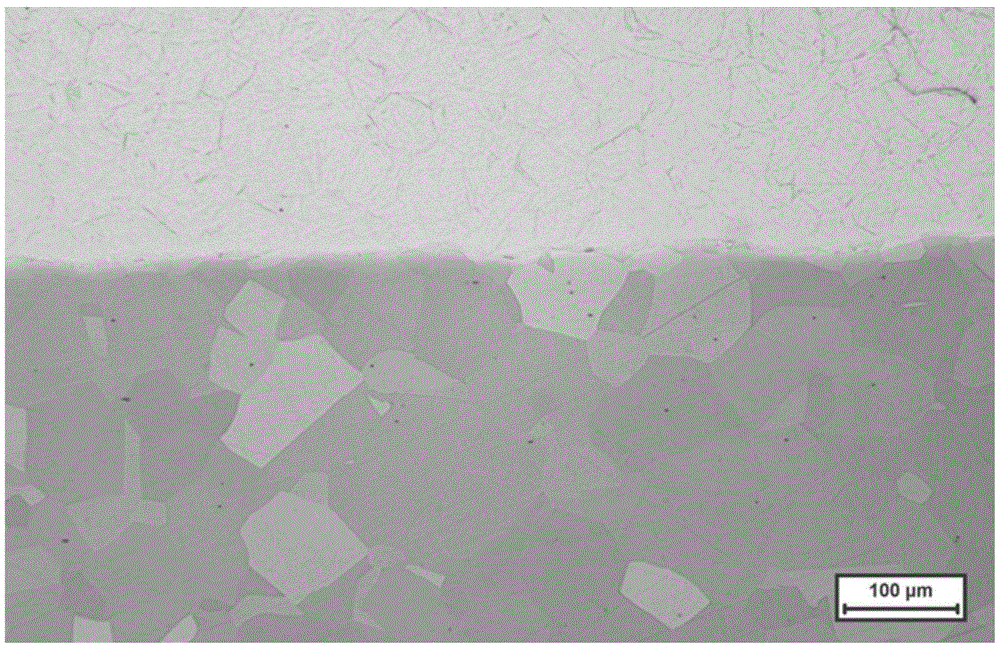

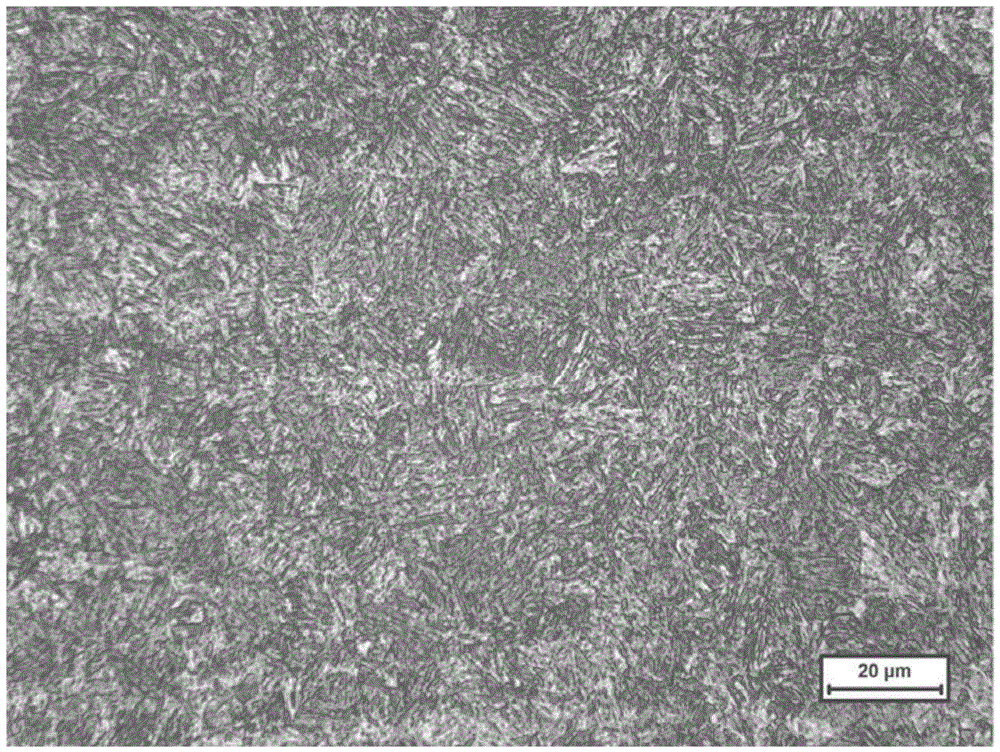

[0080] The three-layer composite steel plate in the above-mentioned embodiment is prepared by the following steps:

[0081] (1) prepare high-hardness layer slab and low-hardness layer slab respectively, and control each chemical element in high-hardness layer slab and low-hardness layer slab respectively as shown in Table 1;

[0082] (2) Blank assembly:

[0083] (2a) Carry out rolling blanking for the high-hardness layer slab and the low-hardness layer slab according to actual needs, and the thickness of the blank is determined according to the thickness of the finished three-layer composite steel plate and the thickness ratio of the high-hardness layer and the low-hardness layer;

[0084] (2b) Pre-treat the joint surface of the slab, use a milling machine or a planer to process the joint surfaces of the high-hardness layer slab and the low-hardness layer slab respectively, remove defects such as iron oxide scale or slag inclusions on the surface of the slab, and then After o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com