High-weather-resistant cold heading steel for 10.9 grade fastener and production method of high-weather-resistant cold heading steel

A production method and fastener technology, applied in the field of cold heading steel production, can solve the problems that the weather resistance index I value does not reach 7.0, cannot be used to make high-strength fasteners, etc., and achieve the goal of increasing corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

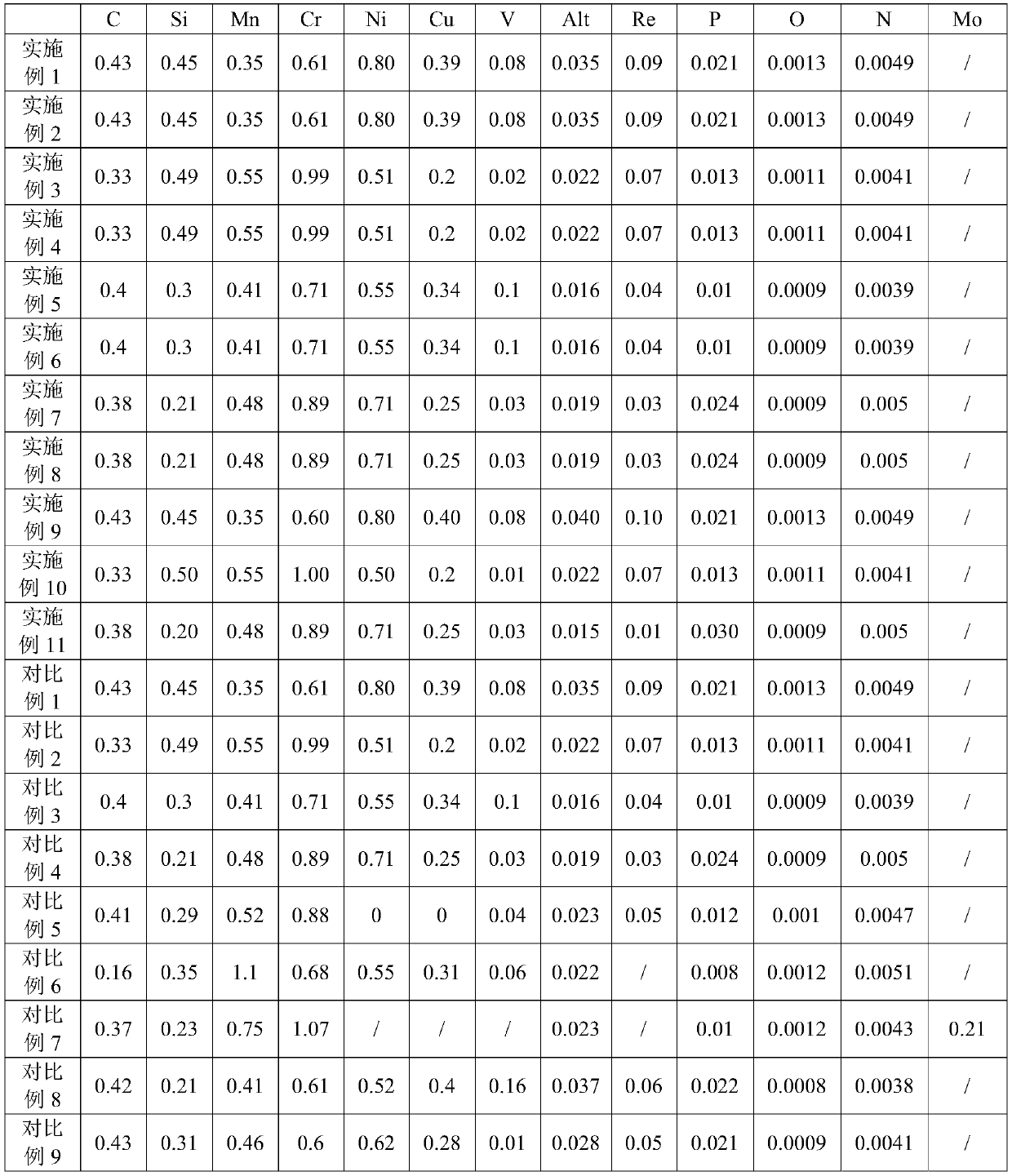

[0085] The main chemical composition and mass percentage of the high weather-resistant cold heading steel for 10.9-grade fasteners in this embodiment are shown in Example 1 in Table 1.

[0086] A production method of high-weather-resistant cold-heading steel for 10.9 grade fasteners of this embodiment includes the following steps on the basis of the ingredients of this embodiment:

[0087] S1. Electric furnace smelting; during the smelting process, the oxygen is fixed before tapping, and the steel is left during the tapping process to avoid slag.

[0088] S2, LF furnace refining: during the LF furnace refining process, adjust elements such as C, Si, Mn, Cr, Ni, Cu, V, Re, P to the target value.

[0089] S3, RH vacuum degassing; degassing time ≥ 15 minutes, [H] content ≤ 1.5ppm after vacuum treatment, to avoid hydrogen embrittlement of bolts.

[0090] S4. Billet continuous casting; the temperature of the molten steel in the tundish is controlled at 10-40°C above the liquidus l...

Embodiment 2

[0099] The main chemical composition and mass percentage of a high weather-resistant cold heading steel for 10.9-grade fasteners in this embodiment are shown in Example 2 in Table 1.

[0100] A production method of high-weather-resistant cold-heading steel for 10.9 grade fasteners of this embodiment includes the following steps on the basis of the ingredients of this embodiment:

[0101] S1. Electric furnace smelting; during the smelting process, the oxygen is fixed before tapping, and the steel is left during the tapping process to avoid slag.

[0102] S2, LF furnace refining: during the LF furnace refining process, adjust elements such as C, Si, Mn, Cr, Ni, Cu, V, Re, P to the target value.

[0103] S3, VD vacuum degassing; degassing time ≥ 15 minutes, [H] content ≤ 1.5ppm after vacuum treatment, to avoid hydrogen embrittlement of bolts.

[0104] S4. Billet continuous casting; the temperature of the molten steel in the tundish is controlled at 10-40°C above the liquidus lin...

Embodiment 3

[0113] The main chemical composition and mass percentage of the high weather-resistant cold heading steel for 10.9-grade fasteners in this embodiment are shown in Example 3 in Table 1.

[0114] A production method of high-weather-resistant cold-heading steel for 10.9 grade fasteners of this embodiment includes the following steps on the basis of the ingredients of this embodiment:

[0115] S1. Converter smelting; during the smelting process, the oxygen is fixed before tapping, and the steel is left during the tapping process to avoid slag.

[0116] S2, LF furnace refining: during the LF furnace refining process, adjust elements such as C, Si, Mn, Cr, Ni, Cu, V, Re, P to the target value.

[0117] S3, RH vacuum degassing; degassing time ≥ 15 minutes, [H] content ≤ 1.5ppm after vacuum treatment, to avoid hydrogen embrittlement of bolts.

[0118] S4. Billet continuous casting; the temperature of the molten steel in the tundish is controlled at 10-40°C above the liquidus line, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com