Wear-resistant self-lubricating anticorrosive coating material, preparation method and applications thereof

A self-lubricating anti-corrosion technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of low bonding strength between the coating and the base metal, microscopic defects of the coating, low bonding force, holes, and clamping Slag, cracks and other problems, to achieve the effect of reducing the friction coefficient, high waterproof performance, high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

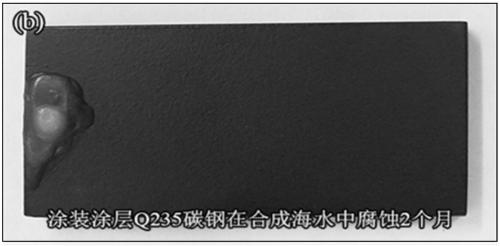

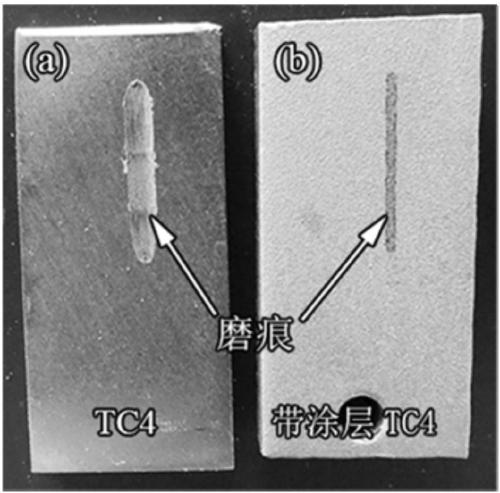

Examples

preparation example Construction

[0025] The preparation method of above-mentioned wear-resistant self-lubricating anti-corrosion coating is:

[0026] First, put the anti-corrosion filler, wear-resistant filler and self-lubricating filler into a dry powder mixing pulverizer and mix and stir at a speed of 500-5000 rpm for 1-5 minutes, then take it out to obtain a composite filler; the function of the composite filler in the present invention is: composite filler Contains anti-corrosion fillers, wear-resistant fillers and self-lubricating fillers, single anti-corrosion fillers, wear-resistant fillers and self-lubricating fillers can only achieve anti-corrosion, wear-resistant and self-lubricating functions, the invention uses anti-corrosion, wear-resistant and self-lubricating composite The filler makes the coating have anti-corrosion, wear-resistant and self-lubricating functions at the same time. At the same time, through the grinding and dispersion process, the anti-corrosion filler, wear-resistant filler and ...

Embodiment 1

[0031] In this example, in parts by mass, 3 parts of glass flake powder (average thickness 2 μm, length 40 μm), 8 parts of zinc powder (average particle size 20 μm), 5 parts of SiC powder (average particle size 1 μm), 8 parts of enamel powder (average particle size 10 μm), 6 parts of graphite powder (average particle size 15 μm) and 2 parts of tungsten disulfide powder (average particle size 5 μm) were put into a dry powder mixing pulverizer and mixed at a speed of 1000 rpm for 3 minutes and then taken out to obtain a composite filler; 30 parts of polyester modified silicone resin, 70 parts of E44 epoxy resin, composite filler, 0.5 parts of LS-333 leveling agent, 1 part of BYK110 wetting and dispersing agent, 0.3 parts of BYK019 defoamer, 30 parts of xylene, stirring After uniformity, put 60 parts of grinding beads with a particle size of 1 mm into a paint grinding and dispersing machine at a speed of 2500 rpm for 35 minutes, take it out, filter it with a 200-mesh stainless ste...

Embodiment 2

[0035] In the present embodiment, in parts by mass, 8 parts of zinc phosphate powder (average particle size 30 μm), 12 parts of phosphorus iron powder (average particle size 25 μm), 9 parts of zinc powder (average particle size 16 μm), 2 parts of enamel powder (average particle size Particle size 2 μm), 5 parts of zirconia powder (average particle size 20 μm), 6 parts of carbon fiber powder (average thickness 5 μm, length 30 μm) and 12 parts of molybdenum disulfide powder (average particle size 5 μm) were mixed in a dry powder mixing grinder at a speed of 5000 rpm Take it out after stirring for 2 minutes to prepare composite filler; weigh 10 parts of methyl silicone resin, 50 parts of E51 epoxy resin, composite filler, 0.7 parts of B381 leveling agent, 1.2 parts of FX365 wetting and dispersing agent, 0.5 parts of ACP1266 defoaming agent agent, 45 parts of xylene, after stirring evenly, put them together with 60 parts of grinding beads with a particle size of 1 mm in a paint gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com