Method for preparing homogeneous phase ion exchange membrane

A technology of homogeneous ion exchange and ion exchange membrane, applied in the field of preparation of homogeneous ion exchange membrane, can solve the problems of high membrane brittleness, poor acid and alkali resistance, etc., and achieves low membrane resistance, low production cost, and mechanical strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

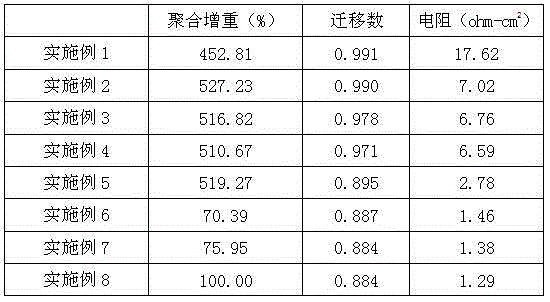

Examples

Embodiment 1

[0025] (1) Membrane liquid preparation: Mix 5.3700 g of glycidyl methacrylate, 15.7309 g of styrene, 1.5210 g of divinylbenzene and 0.3256 g of azobisisobutyronitrile to prepare a uniform solution to obtain a membrane liquid. The molar ratio of glycidyl methacrylate to styrene is 0.25:1, the molar ratio of divinylbenzene to functional monomer is 5:100, and the amount of initiator is 1% of the sum of moles of functional monomer and crosslinking agent .

[0026] (2) Membrane liquid adsorption: UHMWPE porous membrane with a pore size of 0.9 μm, a porosity of 85%, and a thickness of 70 μm was used as the substrate, and the substrate was immersed in the membrane solution prepared in step (1) for 30 min After it is fully impregnated, take out the substrate and place it between two polyethylene terephthalate films. If there are air bubbles between the substrate and the film, roll the film to remove the air bubbles between the substrate and the film. The base material and the two fil...

Embodiment 2

[0030] (1) Membrane liquid preparation: Mix 7.5180 g of glycidyl methacrylate, 12.8469 g of styrene, 3.4929 g of ethylene glycol dimethacrylate and 0.6367 g of azobisisobutyronitrile, and prepare a uniform solution to obtain Membrane fluid. The molar ratio of glycidyl methacrylate to styrene is 0.43:1, the molar ratio of ethylene glycol dimethacrylate to functional monomer is 10:100, and the amount of initiator is equal to the molar number of functional monomer and crosslinking agent. and 2%.

[0031] (2) Membrane liquid adsorption: UHMWPE porous membrane with a pore size of 0.9 μm, a porosity of 85%, and a thickness of 70 μm was used as the substrate, and the substrate was immersed in the membrane solution prepared in step (1) for 30 min After it is fully impregnated, take out the substrate and place it between two polyethylene terephthalate films. If there are air bubbles between the substrate and the film, roll the film to remove the air bubbles between the substrate and t...

Embodiment 3

[0035] (1) Membrane solution preparation: Mix 9.6660 g of glycidyl methacrylate, 106183 g of styrene, 1.3689 g of divinylbenzene and 0.1465 g of azobisisobutyronitrile to prepare a uniform solution to obtain a membrane solution. The molar ratio of glycidyl methacrylate to styrene is 0.67:1, the molar ratio of divinylbenzene to functional monomer is 5:100, and the amount of initiator is 0.5% of the sum of moles of functional monomer and crosslinking agent .

[0036] (2) Membrane liquid adsorption: UHMWPE porous membrane with a pore size of 0.9 μm, a porosity of 85%, and a thickness of 70 μm was used as the substrate, and the substrate was immersed in the membrane solution prepared in step (1) for 30 min After it is fully impregnated, take out the substrate and place it between two polyethylene terephthalate films. If there are air bubbles between the substrate and the film, roll the film to remove the air bubbles between the substrate and the film. The base material and the two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com