Multi-block polyurethane shape memory high molecule material and preparation method thereof

A technology of polymer materials and polyurethane, applied in the field of shape memory polymer materials and its preparation, can solve the problems of slow degradation of PCL and achieve good biodegradability, high mechanical strength and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

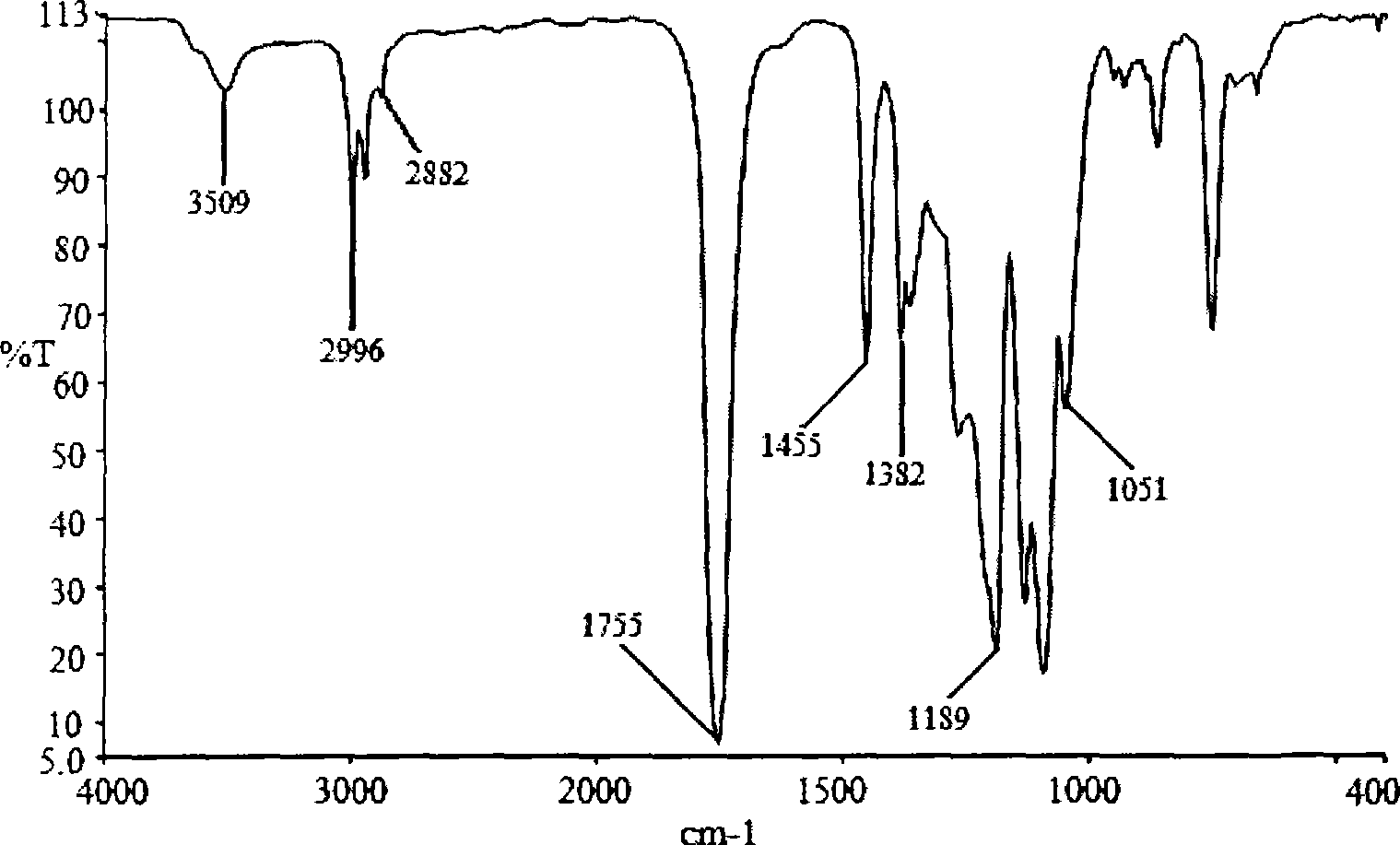

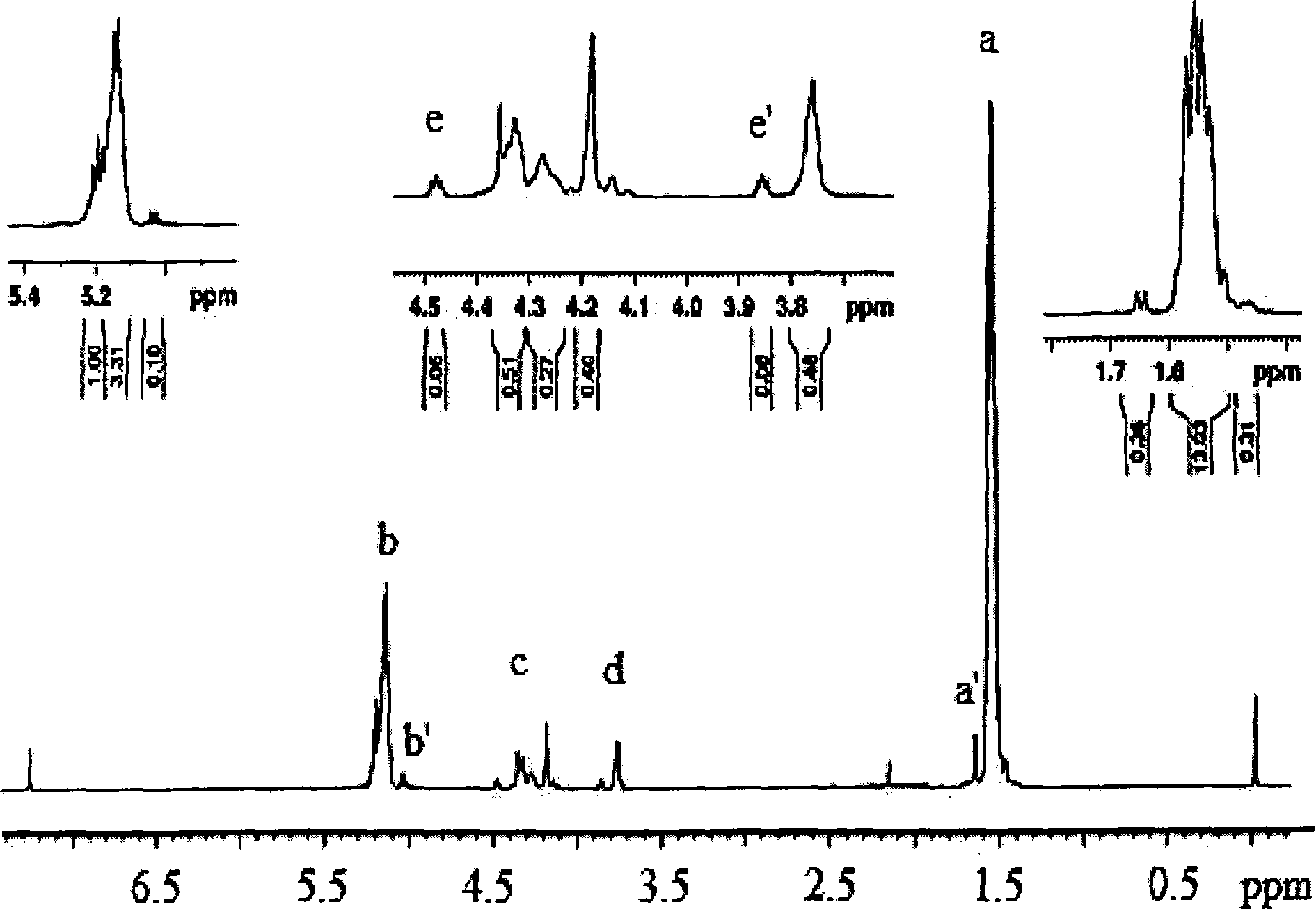

Method used

Image

Examples

Embodiment 1

[0031] Weigh 5.000 g (0.03472 mol) of D, L-lactide (LA) which has been distilled and recrystallized, and 1.25 mL (density: 1.266 g / mL, 0.01551mol), chloroform solution of stannous octoate (T-9) 16.1uL (3.4×10 -6 mol), ethylene glycol 32uL, mix well, and vacuumize for 10-20min. After sealing, place it in a constant temperature oil bath at 130°C for 16 hours. The reaction product was dissolved in acetone, purified with n-hexane, and dried under vacuum at room temperature to obtain 3.8 g of hydroxyl-terminated polymer HO-P(LA-co-PDO)-OH. The number average molecular weight measured by terminal hydroxyl analysis method is 2100, T g = 20.54°C.

Embodiment 2

[0033] Weigh 5.000 g (0.03472 mol) of D, L-lactide (LA) which has been distilled and recrystallized, and 1.25 mL (density: 1.266 g / mL, 0.01551mol), chloroform solution of stannous octoate (T-9) 16.1uL (3.4×10 -6 mol), diethanolamine 55uL, mix thoroughly and evenly, and vacuumize for 10-20min. After sealing, place it in a constant temperature oil bath at 130°C for 16 hours. The reaction product was dissolved in acetone, purified with n-hexane, and dried under vacuum at room temperature to obtain 3.6 g of hydroxyl-terminated polymer HO-P(LA-co-PDO)-OH. The number average molecular weight measured by terminal hydroxyl analysis method is 2400, T g = 21.98°C.

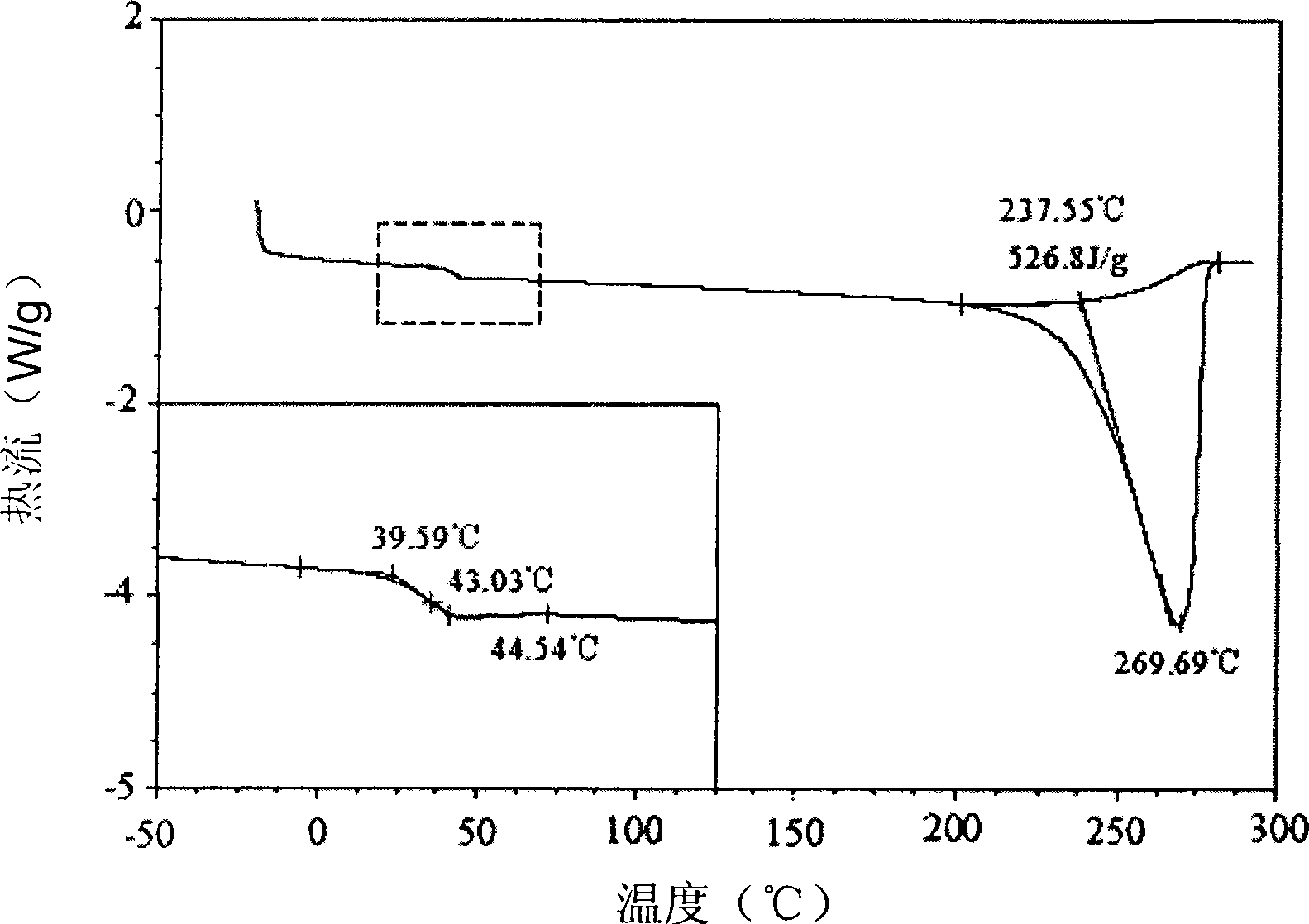

Embodiment 3

[0035] Weigh 5.000 g (0.03472 mol) of distilled and recrystallized D, L-lactide (LA), 0.40 mL (density: 1.266 g / mL, 0.00496mol), chloroform solution of stannous octoate (T-9) 12.8uL (2.7×10 -6 mol), ethylene glycol 32uL, mix well, and vacuumize for 10-20min. After sealing, place it in a constant temperature oil bath at 140°C for 24 hours. The reaction product was dissolved in acetone, purified with n-hexane, and dried under vacuum at room temperature to obtain 3.9 g of hydroxyl-terminated polymer HO-P(LA-co-PDO)-OH. The number average molecular weight measured by terminal hydroxyl analysis method is 19970, T g = 39.59°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com