Manual shale physical model and manufacturing method and application thereof

A physical model and manufacturing method technology, applied in the field of geophysical research, can solve the problems of low Poisson's ratio, low sample density, low yield of sintering method, etc., and achieve the effect of low Poisson's ratio and high elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a kind of artificial shale physical model, and its raw material composition comprises:

[0040] Adhesive: YY505 epoxy AB glue (Yancheng One Plus One Electronic Material Co., Ltd.) 50g, its main performance parameters are as follows: YY505A, transparent mucus, viscosity 1200~1800CPS / 25℃; YY505B, light yellow mucus, viscosity 800~1200CPS / 25°C; In addition, the specific gravity of liquid A at 25°C is 1.12±0.05g / cm 3 , the specific gravity of liquid B at 25°C is 1.08±0.05g / cm 3 ; The mixing weight ratio of A and B is 2:1. Cured product characteristics: hardness 85±5Shore D, shear strength 34~38Mpa; shrinkage rate≤0.5%;

[0041] Stone powder: 200g of 3000 mesh quartz powder, 200g of 3000 mesh kaolin, 25g of 3000 mesh calcite and 75g of 3000 mesh organic carbon powder.

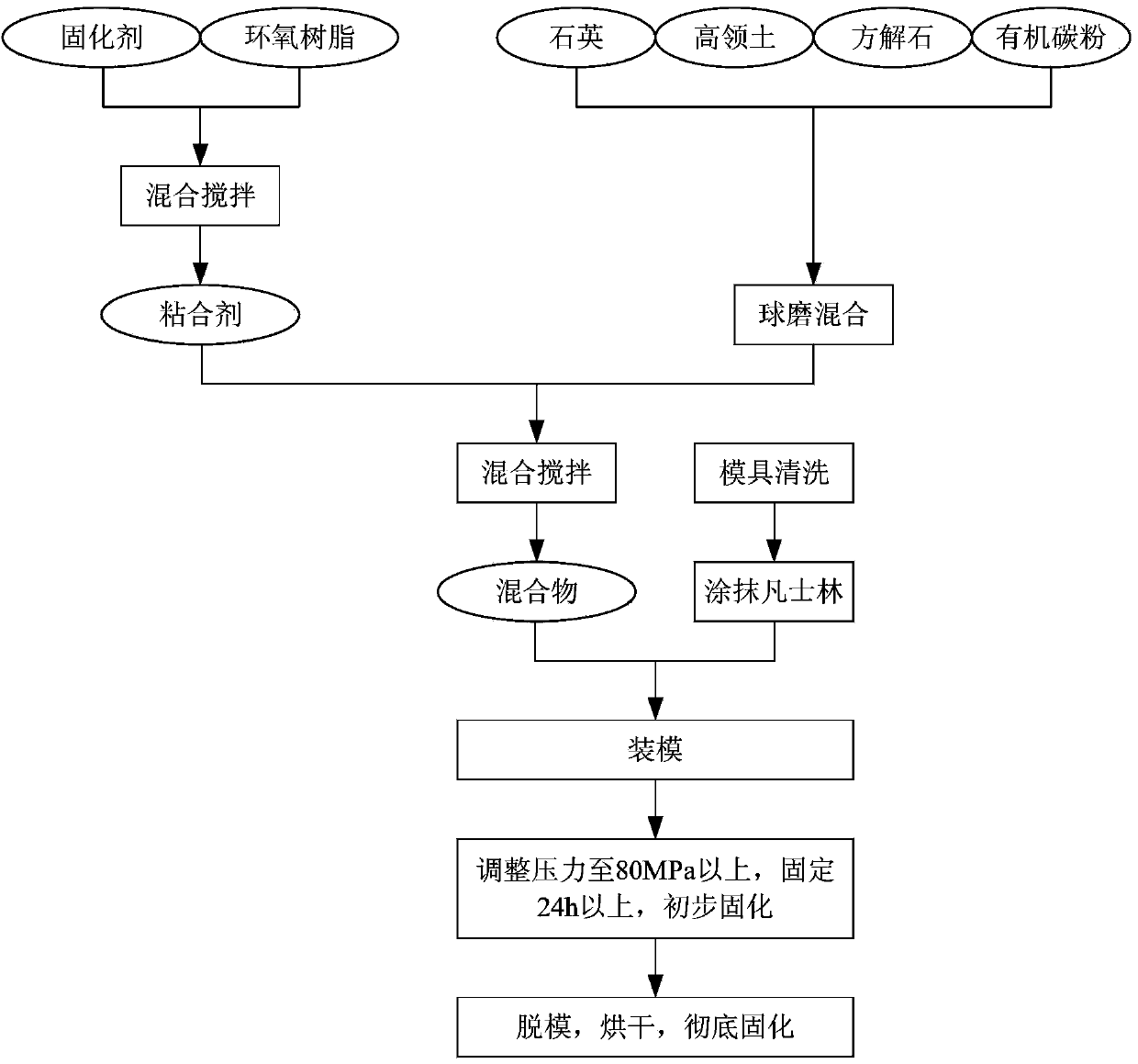

[0042] The present embodiment also provides the manufacturing method of above-mentioned artificial shale physical model, and specific manufacturing process is as follows figure 1...

Embodiment 2

[0049] The artificial shale physical model of the present embodiment, its raw material composition comprises:

[0050] Binder: YY505 epoxy AB glue 55g;

[0051] Stone powder: 200g of 3000 mesh quartz powder, 200g of 3000 mesh kaolin, 25g of 3000 mesh calcite and 75g of 3000 mesh organic carbon powder.

[0052] Compared with Embodiment 1, the manufacturing method of the artificial shale physical model of this embodiment adopts layered filling, and other process conditions are the same as Embodiment 1. The specific operation steps of the layered filling are as follows: evenly divide the mixture of the uniformly stirred binder and stone powder into multiple parts, each with a mass of about 10g; select a part of the mixed mixture and pour it into a cube mold, and after paving Pressurize to 2MPa, compact, then pour the second mixture, pave 2MPa and compact, repeat in turn until all the mixture is added, then place the mold on the pressure device and fix it horizontally, adjust the...

Embodiment 3

[0054] The artificial shale physical model of the present embodiment (recorded as A3), its raw material composition comprises:

[0055] Binder: YY505 epoxy AB glue 78g;

[0056] Stone powder: 200g of 3000 mesh quartz powder, 200g of 3000 mesh kaolin, 50g of 3000 mesh calcite and 150g of 3000 mesh organic carbon powder.

[0057] During production, the pressure: 286MPa, one-piece filling, full pressure for 48 hours, and then stabilized in the mold cavity for 72 hours, and then molded after demoulding. Others are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com