Medium temperature Ag base brazing filler metal and its preparing method

A medium-temperature and solder technology, which is applied in the formulation of new low-cost medium-temperature cadmium-free Ag-based solder and its preparation field, can solve the problems of high price of solder and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

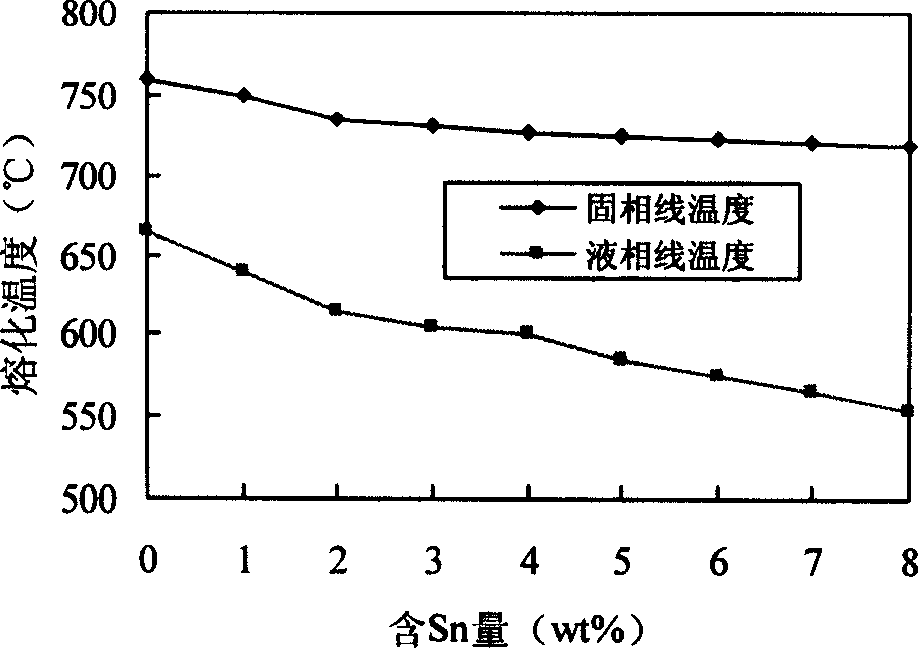

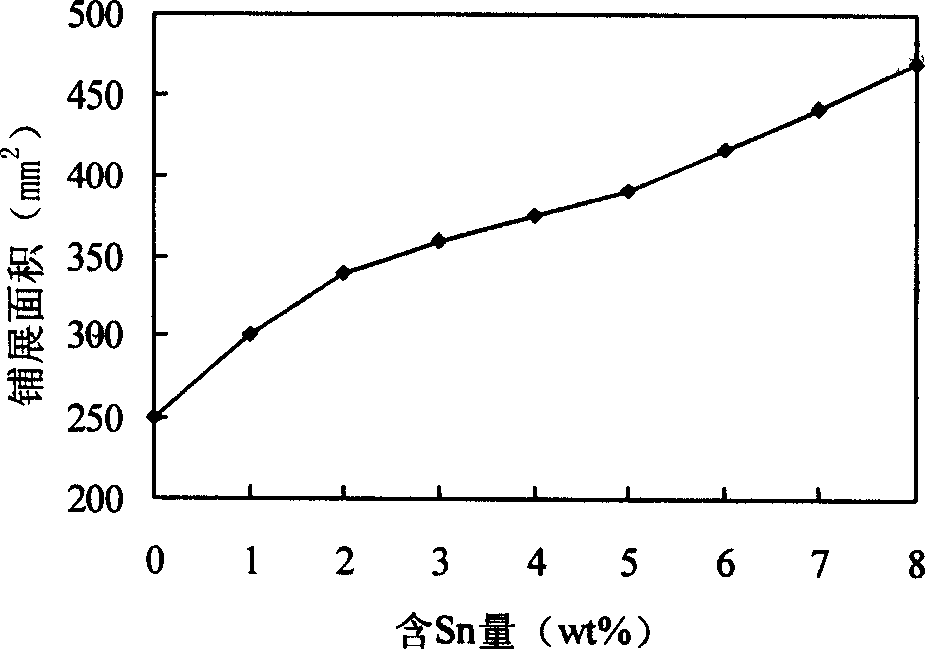

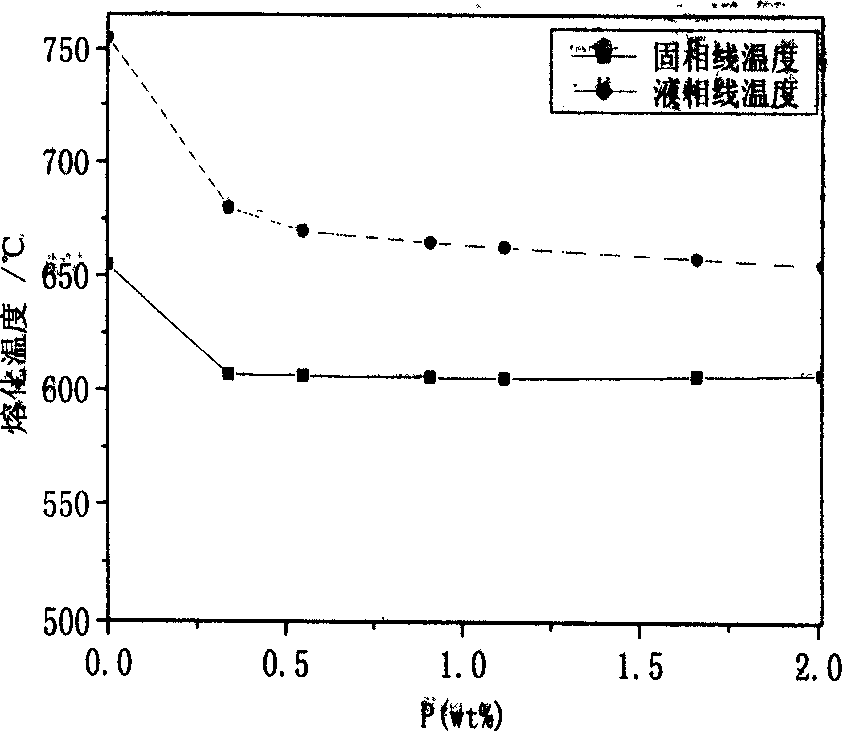

[0006] Specific embodiment one: the medium-temperature Ag-based solder of the present embodiment is made up of seven components of Ag, Cu, Zn, Mn, Sn, P and La, and the weight percentages of each component of the solder are: Ag: 29.5-30.5%, Zn: 31.5-32.5%, Mn: 2.5-3.5%, Sn: 2.5-3.5%, P: 0.4-0.8%, La: 0.2-0.4%, and the balance is Cu.

[0007]The various methods of making medium-temperature Ag-based solder, its preparation steps are: material selection, feeding smelting, casting, extrusion and drawing process, the raw materials used are Ag, Cu, Sn-La, Zn, Cu-Mn, Cu -P, its amount is based on the weight percentage of each raw material in the final product in the following ranges: Ag: 29.5-30.5%, Zn: 31.5-32.5%, Mn: 2.5-3.5%, Sn: 2.5-3.5% , P: 0.4 to 0.8%, La: 0.2 to 0.4%, and the balance is Cu.

specific Embodiment approach 2

[0008] Specific embodiment two: this embodiment is the detailed medium-temperature cadmium-free Ag-based solder preparation method that the applicant has done, and it comprises the following steps successively:

[0009] 1. Addition method of P element: the addition of P needs to pass through the master alloy Cu-P, and the weight content of P in the Cu-P master alloy used in the present invention is 13.5-14%.

[0010] 2. La element addition method: Rare earth elements are active elements, which are easy to oxidize and burn at high temperature, which adds a certain degree of difficulty to the smelting process. If the rare earth elements are directly added, the rare earths will quickly contact with oxygen on the surface of the alloy, and will be burned and cannot enter the alloy. However, due to the Sn-friendly tendency of rare earths, according to the Sn-La phase diagram, it can be seen that after Sn-La is smelted into an alloy, the melting point of the Sn-La alloy increases. Fo...

specific Embodiment approach 3

[0027] Specific Embodiment Three: This embodiment is the preparation process of brazing nickel-free nickel-nickel-nickel (Cu—Sn—B alloy) spectacle frames.

[0028] Brazing process and process specification:

[0029] 1. Surface treatment of the test piece: Since there are oxide films and adsorption layers on the surface of the test piece, and these adsorption layers often affect the brazing quality of the joints, it is necessary to perform necessary film removal treatment before welding. The film method is a manual mechanical film removal method, that is, the surface of the specimen is polished with 240#-1000# water sandpaper, and then rinsed with acetone and absolute ethanol. 2. Selection of heating method: High-frequency induction brazing has the advantages of fast heating speed, easy temperature control, good working environment, easy automatic control of heating specifications, and high pass rate of products, so it is applied to large-scale industrial brazing production , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com