Remelting electroslag premelting material for high alloy steel round billet containing aluminum and titanium and preparation method thereof

A high-alloy steel and electroslag premelting technology, which is applied in the field of electroslag remelting, can solve unknowable problems, achieve the effects of improving productivity, uniform and stable slag composition, and shortening the formation time of slag pools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

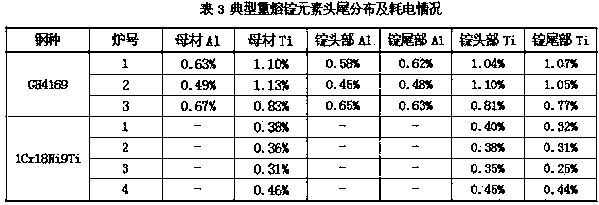

[0032] The above-mentioned components are provided by the following raw materials, and the respective component weight percentages of the raw materials satisfy respectively:

[0033] Lime: CaO ≥96%, SiO 2 ≤1.0%, FeO ≤0.5%, S ≤0.05%, the balance is impurities;

[0034] Fluorite: CaF 2 ≥95%, SiO 2 ≤1.0%, FeO ≤0.5%, S≤0.05%, the balance is impurity;

[0035] Alumina powder: Al 2 o 3 >95%, SiO 2 ≤1.0%, FeO ≤1.0%, S ≤0.05%, the balance is impurities;

[0036] Fused magnesia: MgO ≥ 95%, SiO 2 ≤1.0%, CaO ≤1.5%, the balance is impurity;

[0037] Titanium dioxide: TiO 2 ≥92%, SiO 2 ≤1.0%, the balance is impurities.

[0038] Using the above materials, the cost is low, and the stability of the premelt can be improved, so that the premelt has the following physical properties: the temperature of the hemispherical point is 1300-1350 o C, 1550 o C viscosity is 0.020.05 Pa s, calculated to be 1600 o C conductivity is 2-3 Ω -1 cm -1 .

[0039] A method for preparing a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com