Magnetron sputtering method for preparing HA/YSZ/polyimide bioactive composite material

A magnetron sputtering and bioactive technology, applied in the field of HA bioactive composite materials, can solve problems such as preparation technology limitations, and achieve the effects of avoiding stress shielding, good biomechanical properties, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The artificial bone implant based on the HA biofilm on the PI surface is prepared by the magnetron sputtering process, and the present invention will be further described in conjunction with examples.

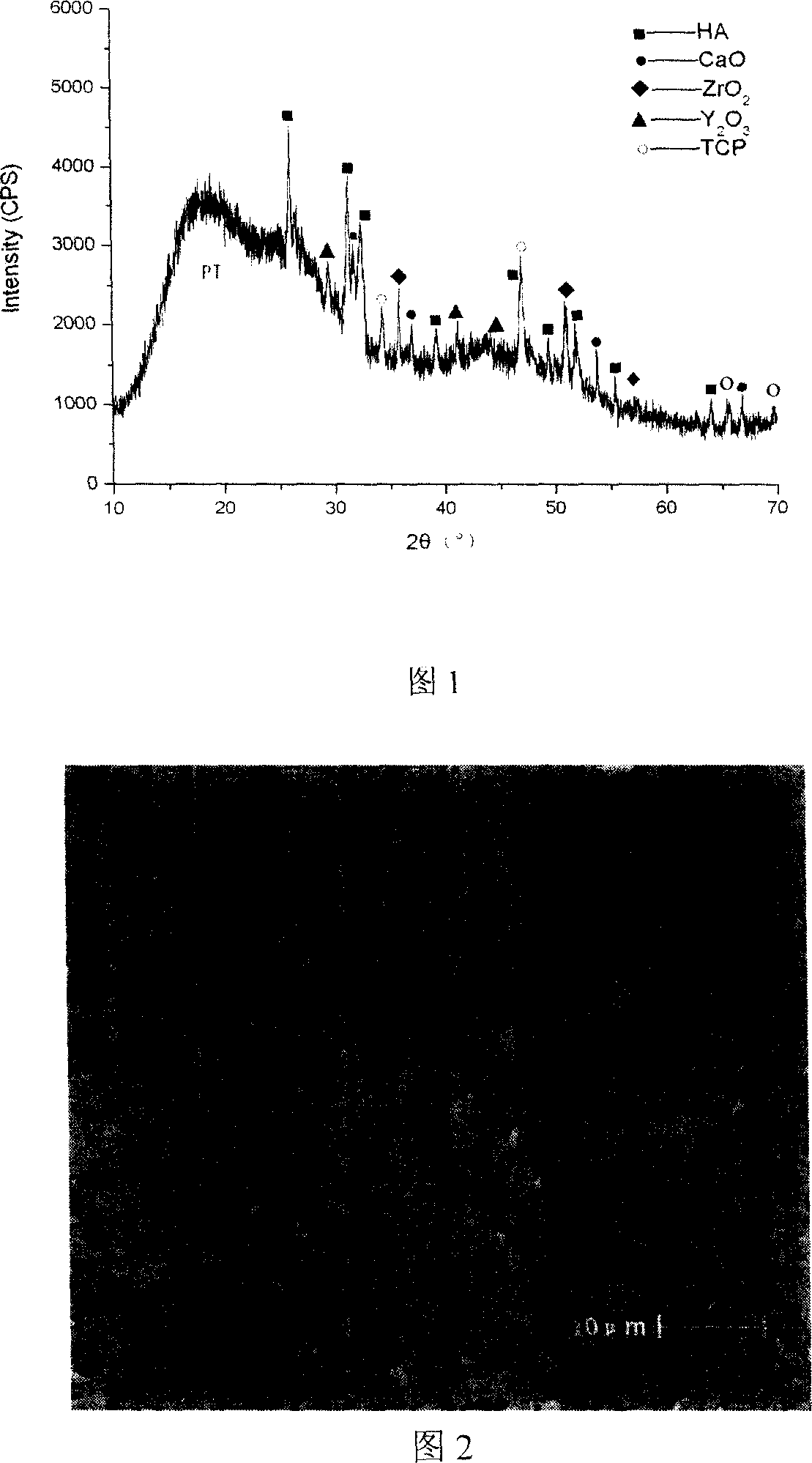

[0020] (1) Preparation of magnetron sputtering HA / YSZ target

[0021] Nanoscale HA powder is prepared by sol-gel method. Mix HA powder and YSZ powder. The mass of YSZ powder accounts for 5%, 10%, 15%, 20%, 25%, and 30% of the total mass of powder. %, 35%, 40%, respectively numbered NO1 ~ NO8, placed in a blast oven to dry, ground and sieved. The HA / YSZ target was prepared in a ZRY55 multifunctional vacuum hot-pressing sintering furnace, the hot-pressing pressure was 5t, the hot-pressing temperature was 1150°C, and the hot-pressing atmosphere was N 2 , hold the pressure for 4h and then cool with the furnace to obtain a magnetron sputtering HA / YSZ target with a size of 60mm×5mm.

[0022] (2) PI substrate surface pretreatment

[0023] The PI substrate was first cleaned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com