Self-repairing and recoverable polyimide insulating film as well as preparation method and application thereof

A polyimide and insulating film technology, which is applied in the field of self-repairing and recyclable polyimide insulating film and its preparation, can solve the problem of limited repair times of polymer matrix, difficulty in achieving material properties, and reduced material use efficiency, etc. problem, to achieve a balance between repair performance and high glass transition temperature, to facilitate recycling and repair, and to ensure the effect of insulating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

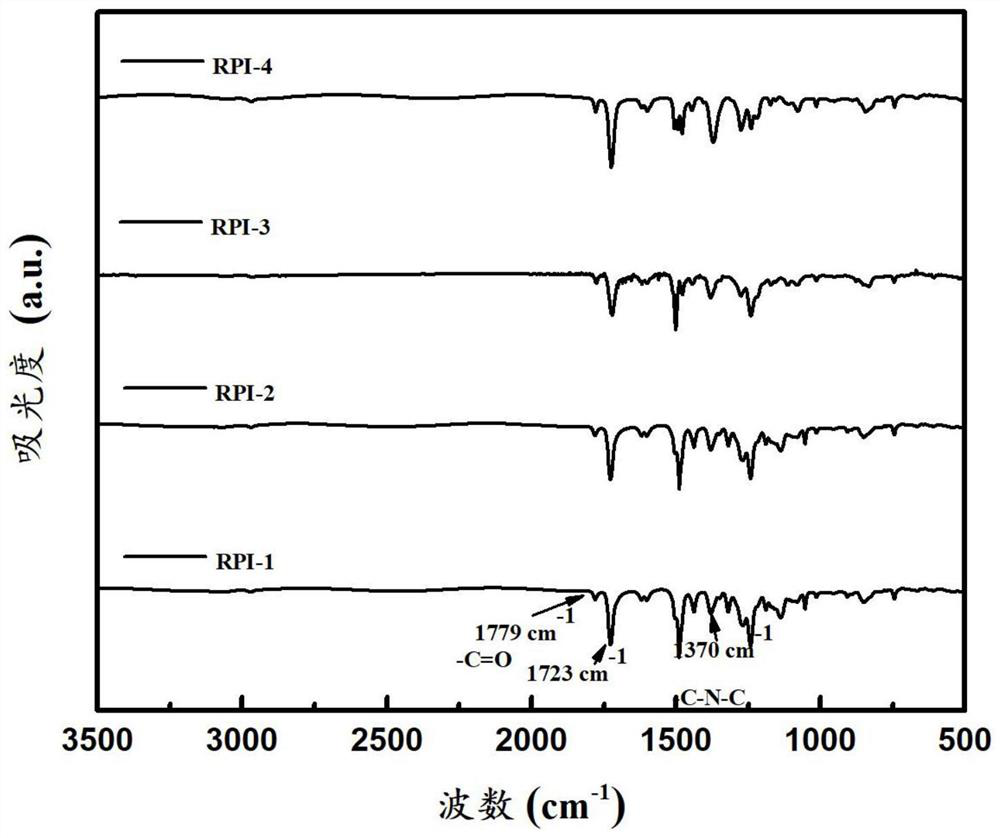

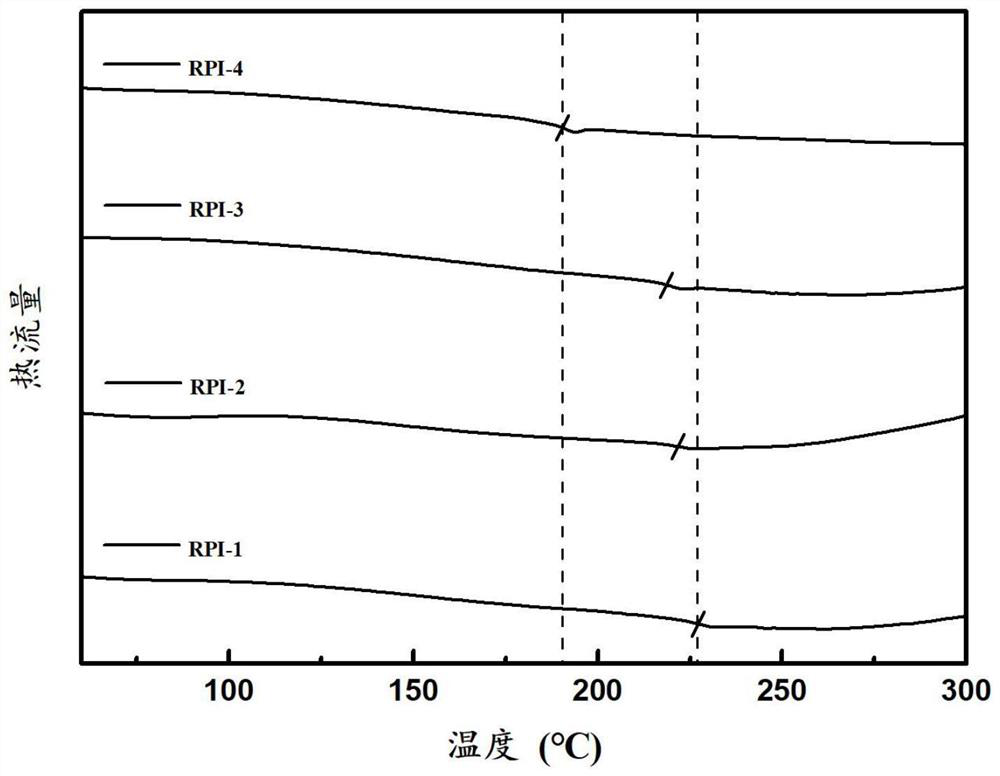

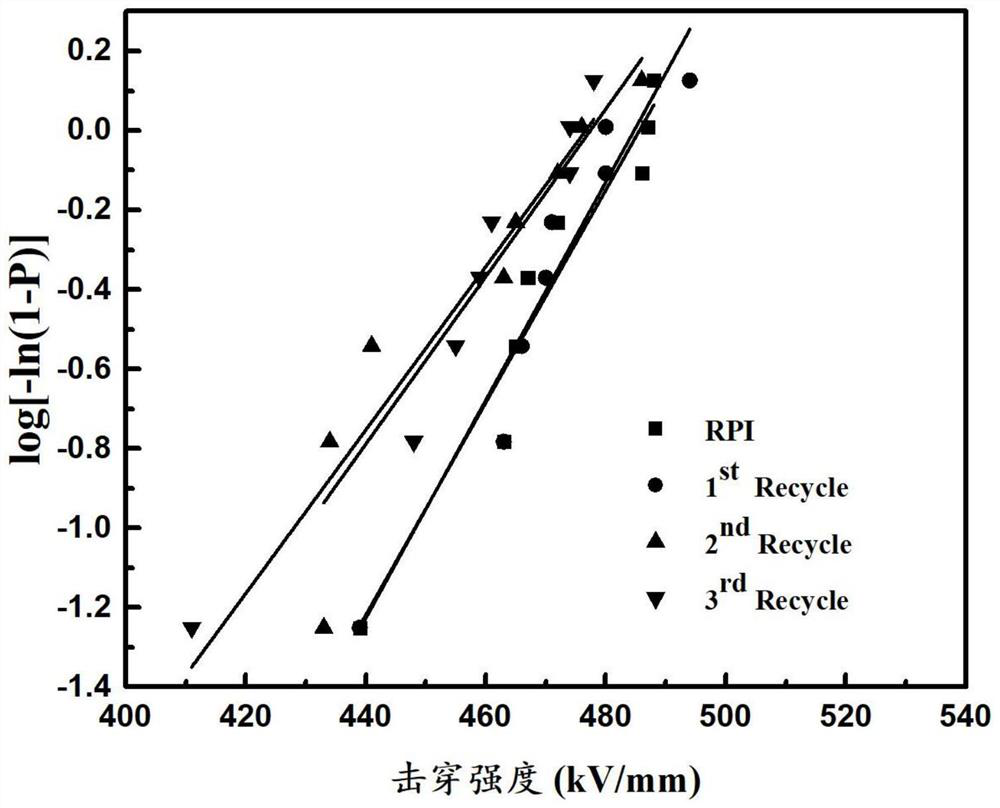

[0041] In the first aspect, a method for preparing self-repairing and recyclable polyimide insulating film is provided, comprising the steps of:

[0042] S1. In the presence of the first solvent, the amino monomer, 4,4'-(4,4'-isopropyldiphenoxy)bis(phthalic anhydride) is subjected to the first polymerization reaction to obtain amino-blocked Terminal copolymerized polyamic acid solution; the amino monomers include 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene (ie 6FAPB) and / or 9,9-bis(3- Fluoro-4-aminophenyl)fluorene (i.e. FFDA);

[0043]S2. The copolymerized polyamic acid solution obtained in step S1 is subjected to azeotropic water removal treatment with an organic solvent, and then subjected to precipitation and drying to obtain amino-terminated low molecular weight copolymerized polyimide powder.

[0044] Preferably, the precipitation is carried out in absolute ethanol.

[0045] S3. In the presence of a second solvent, the polyimide powder obtained in step S2 and the t...

Embodiment 1

[0100] 0.857g 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene and 0.769g 9,9-bis(3-fluoro-4-aminophenyl)fluorene were equally divided into two parts, followed by Dissolve 0.385g of 9,9-bis(3-fluoro-4-aminophenyl)fluorene in 30mL of N-methylpyrrolidone and stir until completely dissolved; then add 1.041g of 4,4'-(4,4' -isopropyldiphenoxy)bis(phthalic anhydride), and in N 2 Stir at 0°C for 30min in the atmosphere; then add 0.429g 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene into the solution, and 2 Stir at 0°C for 30min in the atmosphere; finally add 0.385g 9,9-bis(3-fluoro-4-aminophenyl)fluorene, 0.429g 1,4-bis(4-amino-2-trifluoromethyl Phenoxy) benzene was added at intervals of 30min respectively, and in N 2 Stirred at 0°C for 18h in atmosphere.

[0101] Add 4.5mL of toluene to the polyamic acid solution obtained above and transfer it to a three-necked flask with a Dean-Stark condenser; then heat to 210°C, azeotropically remove water for 9h; then cool the solution to r...

Embodiment 2

[0104] According to the method of Example 1, the difference is that one of the amino monomers is different, specifically, 0.857 g of 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene in Example 1 replaced by 0.585 g of 1,3-bis(4'-aminophenoxy)benzene, and an additional 0.429 g of 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene was replaced by 0.293 g 1,3-bis(4'-aminophenoxy)benzene, other parameters are the same as in Example 1, (that is, two amino monomers, 4,4'-(4,4'-isopropyldi The volume ratio of the total mass of phenoxy) two (phthalic anhydride) and solvent is preferably 2.4g: (25~30) mL), obtain polyimide film, denoted as RPI2, thickness is 15-20 μ m, It can perform multiple monomer recovery and repolymerization, and self-repair under certain conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com