Equipment for preparing chromium zirconium copper alloy wire pole by electromagnetic stirring fusion metallurgy

A technology of electromagnetic stirring and chromium-zirconium copper, which is applied in the field of non-vacuum electromagnetic stirring smelting equipment for preparing chromium-zirconium-copper alloy wire rods, and in the field of equipment for preparing chromium-zirconium-copper alloy wire rods, which can solve the problem of difficult, impossible, unfavorable feeding and observation and other problems, to achieve uniform and stable composition, reduce production costs, and simplify the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

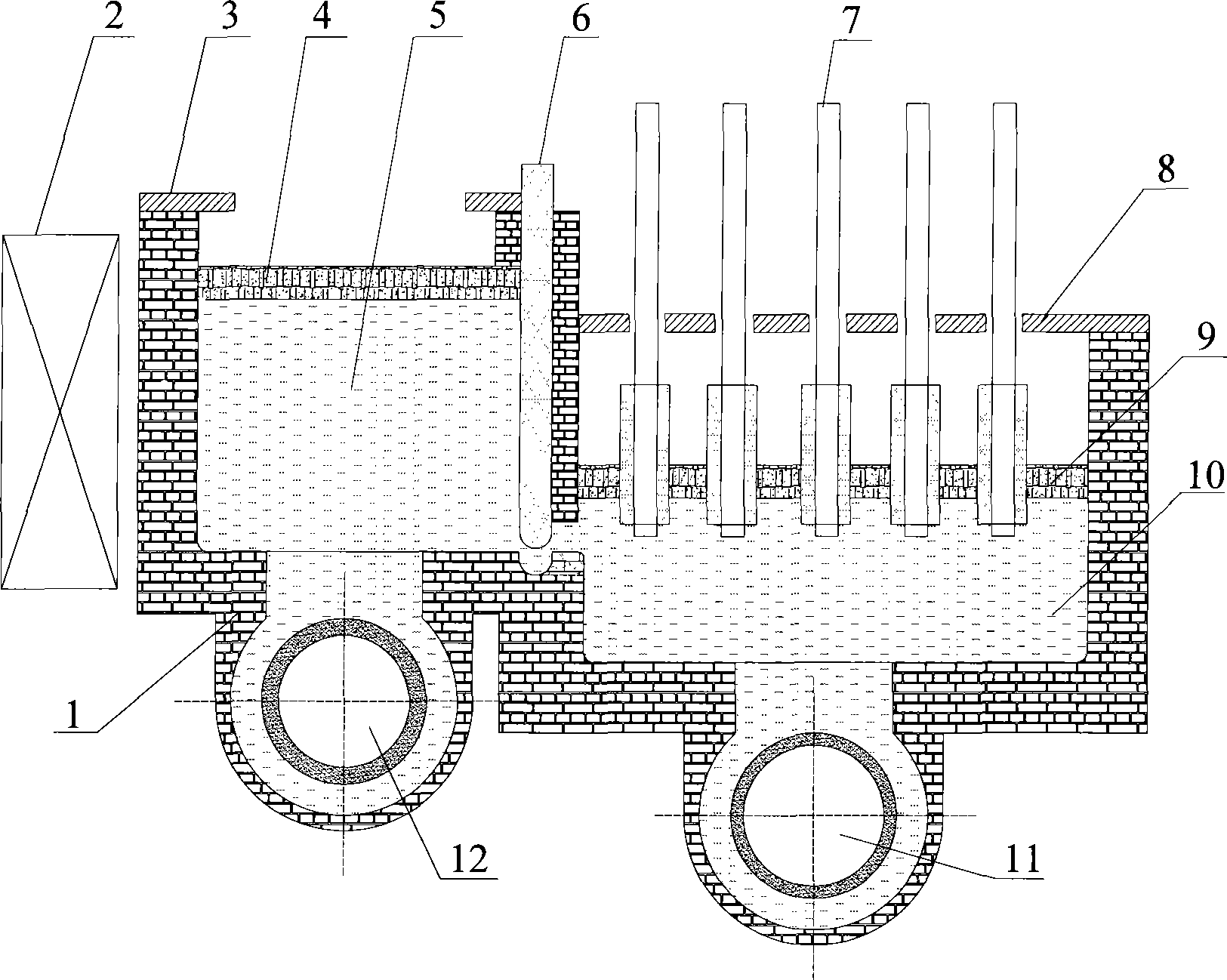

[0017] like figure 1 As shown, the equipment for preparing chrome-zirconium-copper alloy wire rods by electromagnetic stirring smelting includes a furnace body 1 and an upward lead system 7, and a baffle 6 is provided in the middle of the furnace body 1 to divide it into a smelting furnace part 5 and a holding furnace part 10. The furnace bottom of the smelting furnace part 5 is higher than the furnace bottom of the holding furnace part 10. During melting and component modulation, the liquid level of the smelting furnace part is higher than the liquid level of the holding furnace part. After the components are prepared, the smelting furnace part of the liquid is transferred to the holding furnace. part; an electromagnetic stirrer 2 is arranged on the outside of the smelting furnace part 5, a smelting furnace inductor 12 is arranged at the lower part of the smelting furnace part 5, a smelting furnace cover 3 is covered on the top of the smelting furnace part 5, and the smelting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com