Method for preparing MnZn ferrite material powder from acid washing waste liquid and galvanized zinc slag

A technology for pickling waste liquid and ferrite, which is applied in the field of preparing MnZn ferrite powder, can solve the problems of reducing the particle size of magnetic materials, difficult to remove impurities, long process flow, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

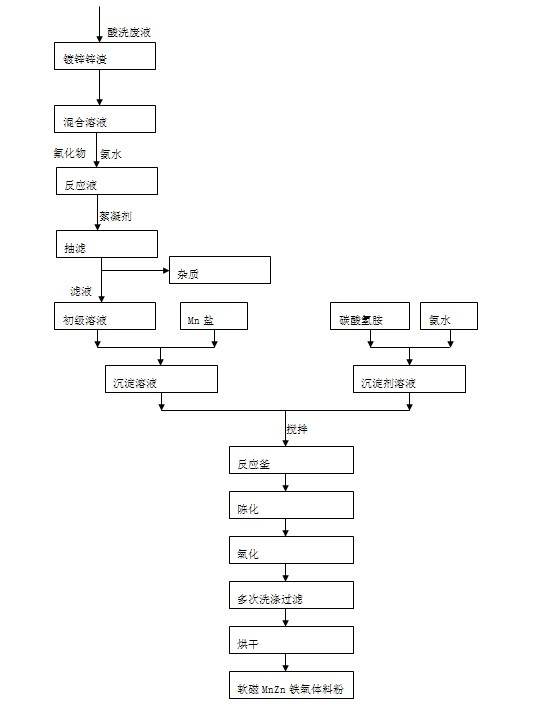

[0028] Example 1: figure 1 Shown, the concrete processing steps of the method for preparing MnZn ferrite material powder by utilizing pickling waste liquor and galvanizing slag are:

[0029] (1) Take 35g of galvanized zinc slag and dissolve it in 1L of pickling waste solution. During the dissolution process, use hydrochloric acid to adjust the pH value of the solution to 1.5, control the system temperature at 40°C, and obtain a mixed solution after complete dissolution;

[0030] (2) Use ammonia water to adjust the pH value of the mixed solution to 5, then take 1.5ml / L of 1wt% ammonium fluoride solution and add it to the mixed solution; react for 1.5h to obtain the reaction solution;

[0031] (3) Add 7.2 mg of 8173 flocculant to each liter of reaction solution; use a filter press to separate the filter cake and discard it, and the resulting filtrate is the primary solution;

[0032] (4) Fe in the primary solution and manganese chloride according to the ferrite composition (sof...

Embodiment 2

[0037] Example 2: figure 1 Shown, the concrete processing steps of the method for preparing MnZn ferrite material powder by utilizing pickling waste liquor and galvanizing slag are:

[0038] (1) Take 32g of galvanized zinc slag and dissolve it in 1L of pickling waste solution. During the dissolution process, use hydrochloric acid to adjust the pH value of the solution to 1, and control the temperature of the system at 50°C. After the dissolution is complete, a mixed solution is obtained;

[0039] (2) Use ammonia water to adjust the pH value of the mixed solution to 3, then take 1ml / L of 1wt% ammonium fluoride solution and add it to the mixed solution; react for 1 hour to obtain a reaction solution;

[0040] (3) Add 6.8 mg of 8173 flocculant to each liter of reaction liquid; use a filter press to separate the filter cake and discard it, and the resulting filtrate is the primary solution;

[0041] (4) Fe in the primary solution and manganese chloride according to the ferrite co...

Embodiment 3

[0046] Example 3: figure 1 Shown, the concrete processing steps of the method for preparing MnZn ferrite material powder by utilizing pickling waste liquor and galvanizing slag are:

[0047] (1) Take 38g of galvanized zinc slag and dissolve it in 1L of pickling waste solution. During the dissolution process, use hydrochloric acid to adjust the pH value of the solution to 2, control the system temperature at 30°C, and obtain a mixed solution after complete dissolution;

[0048] (2) Adjust the pH value of the mixed solution to 6 with ammonia water, then take 2ml / L of 1wt% sodium fluoride solution and add it to the mixed solution; react for 2 hours to obtain the reaction solution;

[0049] (3) Add 8 mg of polyacrylamide to each liter of reaction solution; separate the filter cake with a filter press and discard, and the resulting filtrate is the primary solution;

[0050] (4) Fe in the primary solution and manganese chloride according to the ferrite composition (soft magnetic Mn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com