Ultrahigh-performance concrete containing basalt coarse aggregate and preparation method of same

A technology of ultra-high performance and coarse aggregate, applied in the field of building materials, can solve the problems of serious autogenous shrinkage, harsh curing conditions, and high production cost of ultra-high performance concrete, and achieve reduced negative impact on mechanical properties and good durability , Inhibit the effect of self-shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

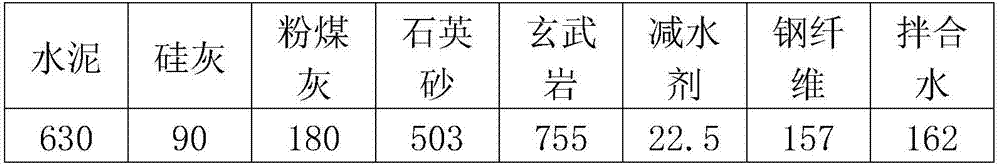

[0030] The present invention has prepared a kind of super high-performance concrete containing basalt coarse aggregate, and its raw material mixing ratio (according to 1m 3 The amount of concrete material) and performance are as follows:

[0031] The cement is P·Ⅱ52.5 ordinary Portland cement with a specific surface area of 400m 2 / kg, 28d compressive strength 58MPa; silica fume: SiO 2 The content is greater than 95%, and the specific surface area is 20000m 2 / kg, the density is 625kg / m 3 ; Fly ash: Class I fly ash, the loss on ignition is not more than 2%, and the density is 2.0g / cm 3 .

[0032] Fine aggregate: quartz sand, SiO 2 Content > 99%, medium sand in Zone II, mud content less than 0.5%, density 2.63g / cm 3 .

[0033] Coarse aggregate: it is basalt, which is uniformly mixed with particle sizes of 5~10mm and 10~20mm according to the mass ratio of 3:7, and the apparent density is 2.82g / cm 3 , The crushing index does not exceed 5%, the mud content is 0%, and the...

Embodiment 2

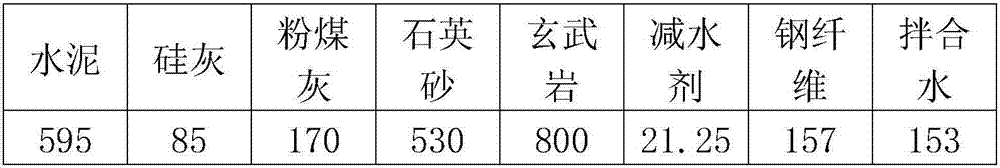

[0051] The ultra-high performance concrete containing basalt coarse aggregate prepared by this implementation example, the raw material mix ratio (1m 3 The dosage of each raw material of ultra-high performance concrete) is shown in Table 2:

[0052] Table 2 Mix design of ultra-high performance concrete containing basalt coarse aggregate (kg / m 3 )

[0053]

[0054] Raw material requirements and preparation method are the same as in Example 1.

Embodiment 3

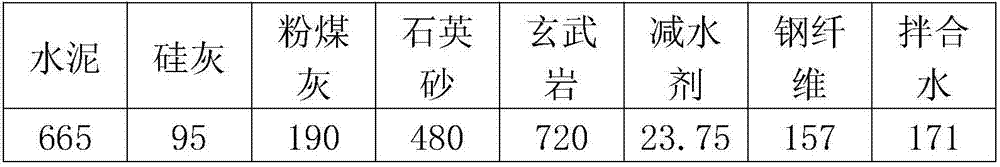

[0056] The ultra-high performance concrete containing basalt coarse aggregate prepared by this implementation example, the raw material mix ratio (1m 3 The dosage of each raw material of ultra-high performance concrete) is shown in Table 3:

[0057] Table 3 Mix design of ultra-high performance concrete containing basalt coarse aggregate (kg / m 3 )

[0058]

[0059] Raw material requirements and preparation method are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com