Alcohol amine-carboxylic acid polymer as well as preparation method and application thereof

A technology of carboxylic acid series and polymers, which is applied in the field of alcohol amine-carboxylic acid series polymers, can solve the problems of unstable performance, high price, sensitive dosage, etc., achieve excellent grinding aid effect, improve compatibility, prevent The effect of particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of above-mentioned alcohol amine-carboxylic acid polymer, comprises the following steps:

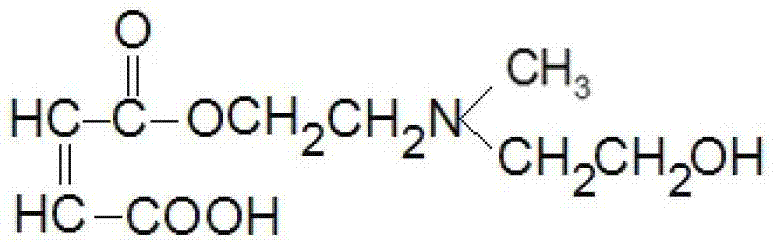

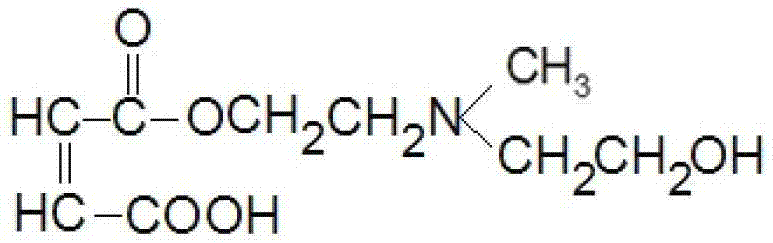

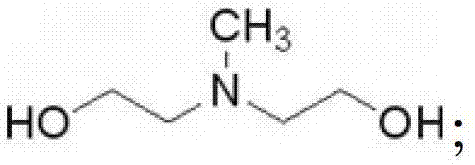

[0031] A, esterification process: carry out esterification reaction to N-methyldiethanolamine, maleic anhydride to prepare N-methyldiethanolamine maleate, also add catalyst, dehydrating agent and polymerization inhibitor in the esterification reaction; The molecular structural formula of N-methyldiethanolamine maleate is as follows:

[0032]

[0033] B. Polymerization process: Copolymerize N-methyldiethanolamine maleate, isopentenol polyoxyethylene ether and initiator in aqueous solution by dropwise addition.

[0034] Wherein, step A specifically includes: sequentially adding N-methyldiethanolamine, maleic anhydride, catalyst, dehydrating agent and polymerization inhibitor into the reaction vessel, heating and stirring continuously, controlling the reaction temperature at 110-120°C, and dehydration reaction After several hours, the dehydrating agent and ...

Embodiment 1

[0051] Add 119.0g N-methyldiethanolamine, 98.0g maleic anhydride, 3.2g concentrated sulfuric acid, 98.0g dehydrating agent, 1.1g Inhibitor, heat up and stir constantly, control the reaction temperature at 110-120°C, react for 4-8 hours, distill under reduced pressure and recover the dehydrating agent and unreacted raw materials, and obtain N-methyldiethanolamine after separation and purification maleate.

[0052] Take 20.0g of the prepared N-methyldiethanolamine maleate and dilute it with 107.0g deionized water to a concentration of 15.7% and add it to the reaction vessel. When the temperature is kept at 85±1°C, use a peristaltic pump to A certain rate drips 35.7 g of ammonium persulfate initiator solution with a concentration of 5.5% after dilution and 143.0 g of prenyl alcohol polyoxyethylene ether solution with a concentration of 50.0% after dilution, and the rate of addition is controlled within 5 hours. After 2-4 hours, cool the obtained product to below 40°C, adjust it ...

Embodiment 2

[0054] Add 80.0g of N-methyldiethanolamine, 65.0g of maleic anhydride, 2.5g of concentrated sulfuric acid, 65.0g of dehydrating agent, 0.72g of sulfuric acid into the reaction vessel equipped with constant temperature oil bath, thermometer, stirrer and condenser etc. Polymerizing agent, heating and stirring constantly, control the reaction temperature at 110-120°C, react for 3-7 hours, distill under reduced pressure and recover dehydrating agent and unreacted raw materials, obtain N-methyldiethanolamine horse after separation and purification to esters.

[0055] Dilute 27.0g of the above-prepared N-methyldiethanolamine maleate with 115.0g of deionized water to a concentration of 19.0% and add it to the reaction vessel. When the temperature is kept at 85±1°C, use a peristaltic pump to the reaction vessel Add 41.5 g of the initiator solution with a concentration of 6.6% after dilution and 149.0 g of prenol polyoxyethylene ether solution with a concentration of 48.3% after diluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com