Instantly grinding scoria micro powder and process for manufacturing the same

A technology of slag micropowder and production process, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high cost, high grinding body consumption, low output per hour, etc., and achieves a wide range of professional applicability , Improve the overall performance, improve the effect of the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention adopts the blast furnace slag of Shanghai Baosteel, and after crushing by the following vertical mill process, the slag micropowder obtained has a unique chemical composition, wherein CaO is 40.83%, Al 2 o 3 14.85%, SiO 2 is 33.12%, MgO is 8.28%, and Fe 2 o 3 is 1.47%, MnO is 0.41%, and S is 0.08%. Due to the CaO and Al in the slag 2 o 3 , MgO and other active components are relatively high, and the average activity coefficient is 1.8-2.0, which makes the vertical mill slag powder have good hydration activity. Due to sufficient pulverization, 92.2% of the particle size is ≤30μm, the median diameter is 8.149μm, and the specific surface area is ≥400m 2 / kg. Using the vertical mill slag micropowder of the present invention to replace ordinary Portland cement in equal amounts can significantly improve the comprehensive performance of concrete, which is characterized by good workability, low heat of hydration, good bleeding, good resistance to ch...

Embodiment 2

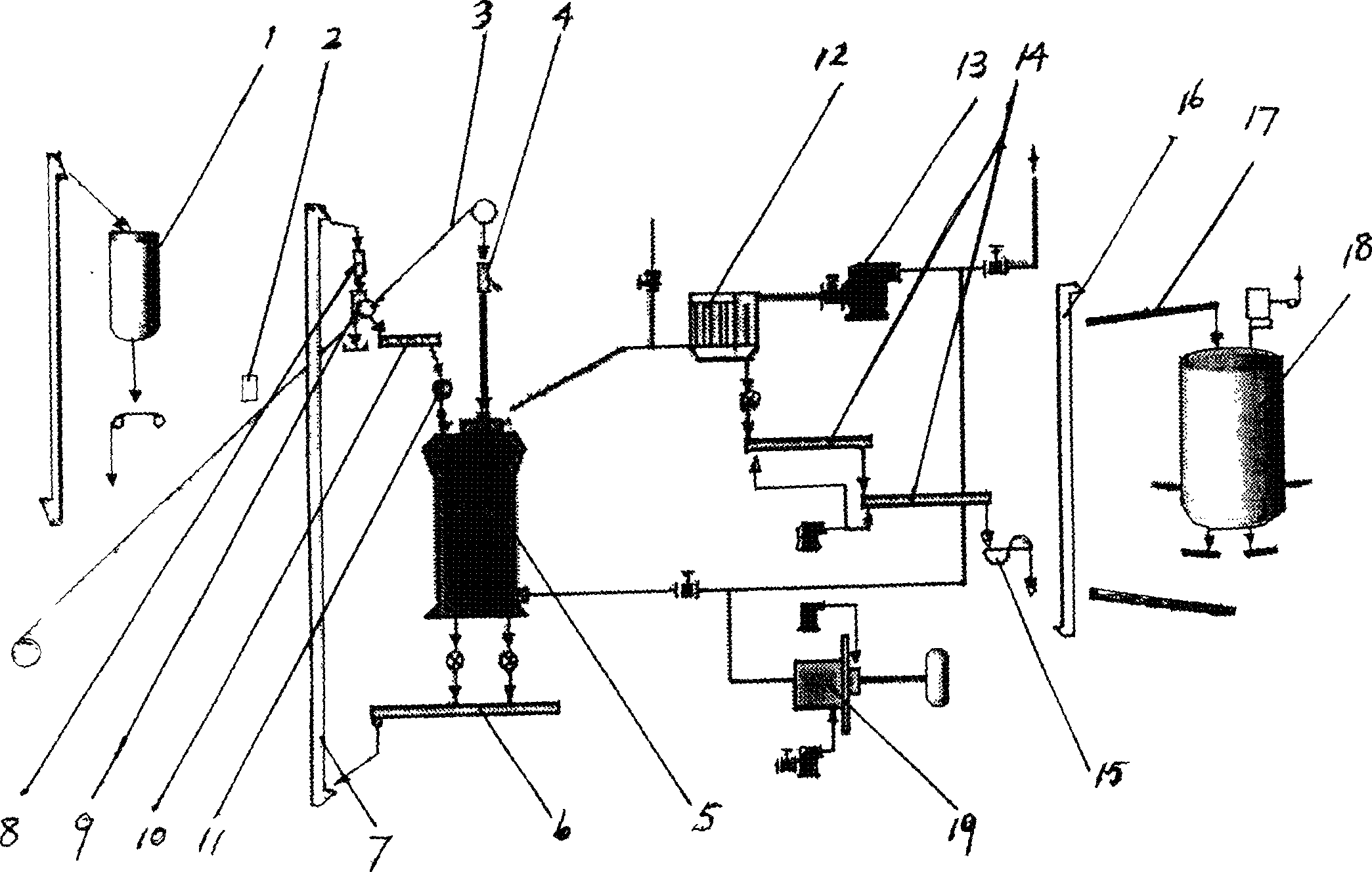

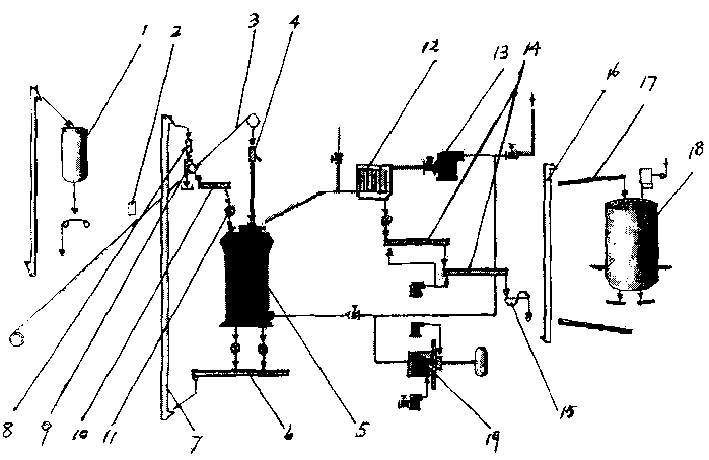

[0027] An example of the production technology of the vertical mill slag micropowder of the present invention can be found in figure 1 .

[0028] (1) Raw material transportation, one-time iron removal: the blast furnace slag raw material in the blast furnace slag bin 1 passes through the conveyor 3, and then goes through the iron remover on the conveyor to remove the iron once to the top of the vertical mill 5, and then feeds it through the air lock feeding valve 4 into the vertical mill 5;

[0029] (2) Slag grinding: The slag raw material fed into the vertical mill is rolled and pulverized by the grinding rollers on the rotating grinding disc in the vertical mill 5, and at the same time is dried by the hot air provided by the hot air system 19, and the fine powder after grinding It is sent to the high-efficiency powder classifier located on the upper part of the vertical mill for sorting, and the qualified fine powder is collected by the bag filter 12; the coarse powder fall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com