Wear-resisting anti-crack cement-based self-leveling mortar and its production method

A self-leveling mortar and cement-based technology, which is applied in the field of building materials, can solve the problems affecting the construction process and the time when the project is put into use, endangering the quality of the self-leveling mortar, and insufficient flatness of the mortar surface, etc., to achieve good anti-foaming effect, The effect of small void ratio and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

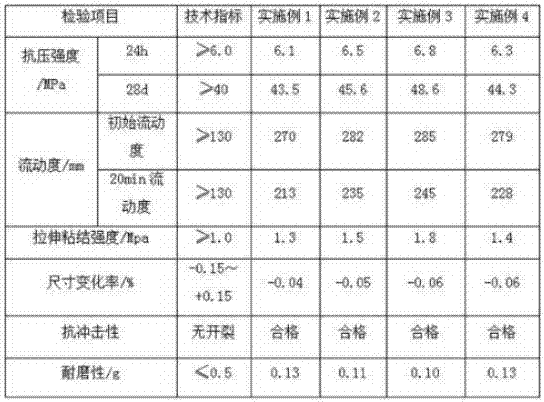

Examples

Embodiment 1

[0029] Raw materials (by weight):

[0030] 20 parts of Portland cement, 10 parts of aluminate cement, 40 parts of aggregate, 10 parts of filler, 5 parts of mineral admixture, 0.5 part of redispersible latex powder, 0.5 part of superplasticizer, 0.5 part of expansion agent, 0.05 parts of shrinkage reducing agent, 0.05 parts of retarder, 0.1 part of water retaining agent (hydroxypropyl methyl cellulose ether), 0.05 parts of superplasticizer (sulfonated melamine formaldehyde condensate), 0.05 parts of defoamer.

[0031] Preparation:

[0032] Under the condition that the speed of the mixer is 100-200rpm, add Portland cement, aluminate cement, aggregate, filler and mineral admixture to the mixer in sequence according to the formula ratio, then increase the speed to 300-400rpm, and stir for 5-10min , and then add redispersible latex powder, high-efficiency water reducer, expansion agent, shrinkage reducer, retarder, water retention agent, superplasticizer and defoamer into the mixe...

Embodiment 2

[0034] 28 parts of Portland cement, 12 parts of aluminate cement, 44 parts of aggregate, 12 parts of filler, 6 parts of mineral admixture, 1 part of redispersible latex powder, 0.8 part of superplasticizer, 1 part of expansion agent, Shrinkage reducing agent 0.1 part, retarder 0.1 part, water retaining agent (cellulose ether or) 0.2 part, superplasticizer (sulfonated naphthalene formaldehyde condensate) 0.06 part, defoamer 0.15 part.

[0035] The preparation method of the above wear-resistant and crack-resistant cement-based self-leveling mortar is the same as in Example 1.

Embodiment 3

[0037] 32 parts of Portland cement, 14 parts of aluminate cement, 48 parts of aggregate, 14 parts of filler, 8 parts of mineral admixture, 1.5 parts of redispersible latex powder, 1.2 parts of superplasticizer, 1.5 parts of expansion agent, 0.15 parts of shrinkage reducing agent, 0.15 parts of setting retarder, 0.25 parts of water retaining agent (hydroxypropyl methylcellulose ether), 0.08 parts of superplasticizer (sulfonated melamine formaldehyde condensate and sulfonated naphthalene formaldehyde condensate), defoaming 0.2 parts of the agent.

[0038] The preparation method of the above wear-resistant and crack-resistant cement-based self-leveling mortar is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com