Device and method for testing interfacial shear strength of fiber reinforced thermosetting resin composite materials

A technology of interfacial shear strength and composite materials, which is applied in the direction of measuring devices, using stable shear force to test material strength, and analyzing materials, can solve the problems of low test efficiency and difficulty in sample preparation for shear strength testing, and achieve Improve the success rate and reliability of results, simplify the structure, and improve the efficiency of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

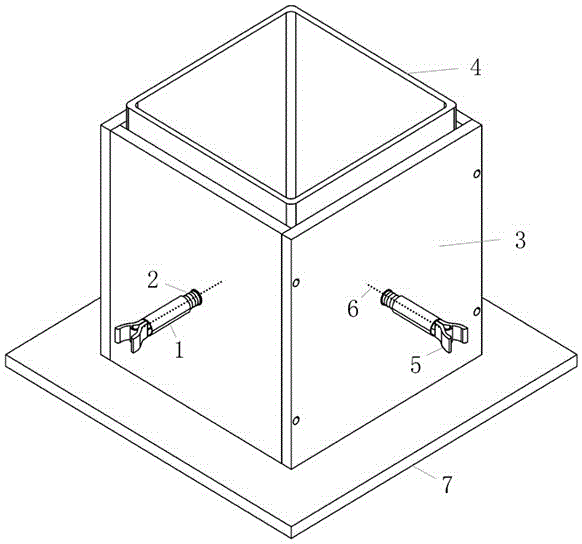

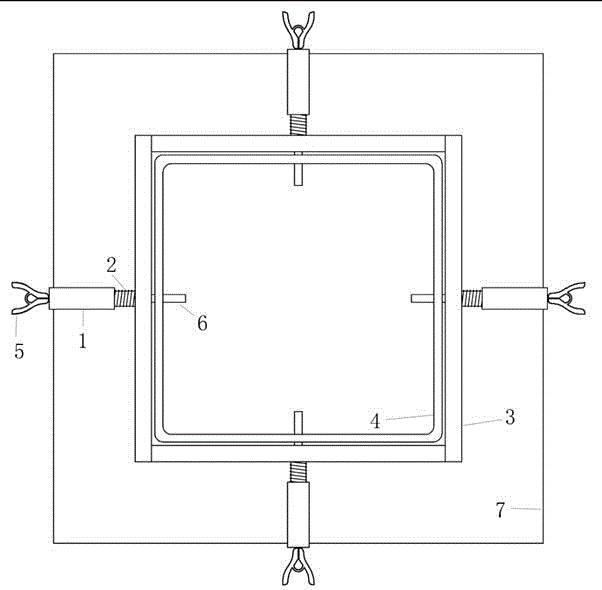

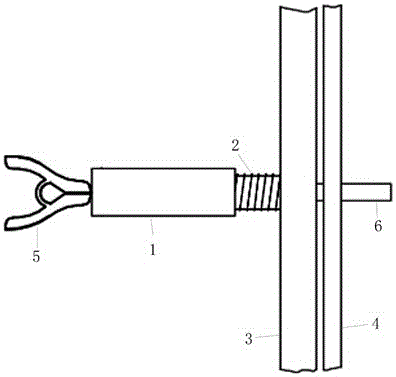

[0032] Embodiment 1: Sisal fiber reinforced epoxy resin matrix composite material

[0033] Fiber-reinforced thermosetting resin-based composite material interface shear strength test device, including resin mold, support plate, hollow screw rod, sleeve, spring clip, bottom support plate, the hollow screw rod is rigidly connected with the support plate, the sleeve It is connected with the hollow screw rod through the internal thread, the support plate is fixed by screws and placed vertically above the bottom support plate, the resin mold is embedded in the middle of the support plate and placed on the bottom support plate, and the pitch of the hollow screw rod is 0.3 mm, the inner diameter is 0.5mm, and the resin mold is a cubic silicone rubber mold with a side length of 10mm.

[0034] Test method for interfacial shear strength of fiber reinforced thermosetting resin matrix composites:

[0035] Present embodiment adopts sisal fiber, and resin matrix is E-51 normal temperatur...

Embodiment 2

[0042] Example 2: Aramid fiber reinforced vinyl unsaturated polyester composite material

[0043] Using the device described in Example 1, this example uses aramid fibers, and the resin matrix is vinyl unsaturated polyester, and proceeds as follows:

[0044] (1) Connect 4 support plates with hollow screw rods by screws, and place them on the bottom support plate, connect the sleeve with the hollow screw rods, and rotate the sleeve until it touches the support plate, vertically place the resin mold Embed directly in the middle of the support plate and place it on the bottom support plate;

[0045] (2) Use a steel needle to guide the aramid fiber through the hollow screw rod and insert it vertically into the resin mold. Trim the end of the fiber with scissors. During the trimming process, the blade is close to the wall of the resin mold so that the length of the fiber embedded in the resin mold after trimming is 2mm;

[0046] (3) Use the spring clamp to clamp the other free e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com