Carbon nanotube modified carbon fiber emulsion sizing agent and preparation method

A carbon nanotube modification and carbon nanotube technology, which is applied in carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems affecting the contribution of carbon nanotube interface bonding strength, difficult industrial application, unfavorable environmental protection, etc., to achieve The requirements for equipment and reaction conditions are not harsh, the process is simple, and the effect of continuous industrial production is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

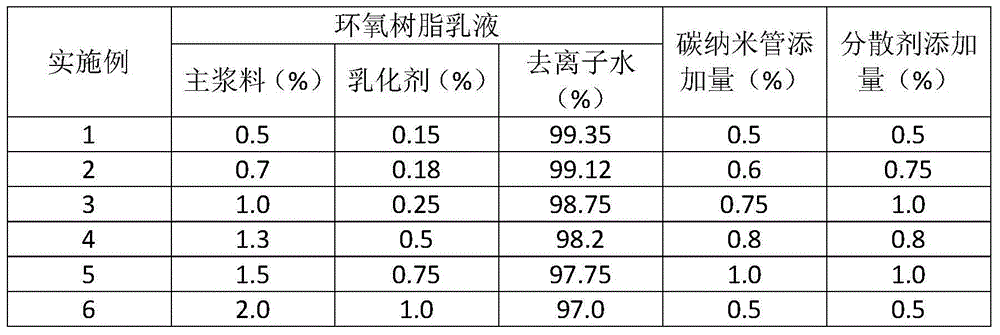

Embodiment 1

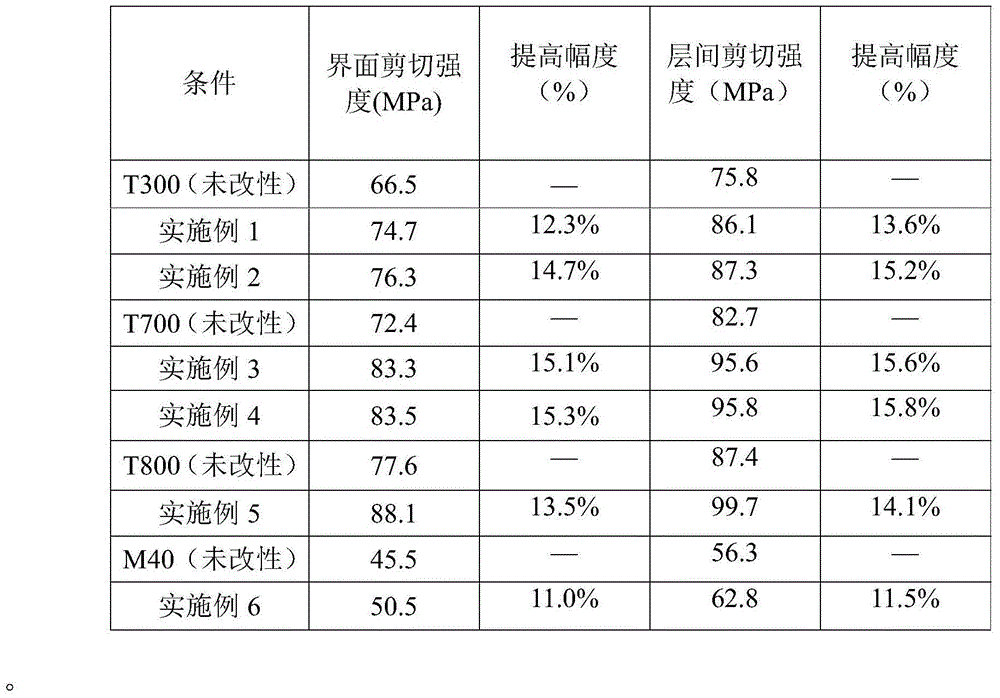

[0023] Weigh respectively main slurry epoxy resin 1.0g, mixed emulsifier sorbitan fatty acid ester (Span60) and sorbitan fatty acid ester polyoxyethylene ether (Tween 80) 0.3g and deionized water 198.7g, wherein mixed emulsified The mass ratio of agent Span60 and Tween 80 is 1:4, and the HLB value is 12.94. Add the main slurry and emulsifier into deionized water, control the temperature of the system at 60°C, and stir at a high speed of 90 minutes with an emulsifier at a speed of 15,000 rpm, and cool to obtain an epoxy resin emulsion. To the obtained epoxy resin emulsion, 1.0 g of carboxylated multi-walled carbon nanotubes having a length of 1 μm and 1.0 g of polyethylene glycol 4000 were added. After mixing evenly, sonicate for 3 hours, and then stir for 11 hours at a rotational speed of 500 rpm to obtain an emulsion-type carbon fiber sizing agent containing carbon nanotubes. The mass fraction of each component in the sizing agent is shown in Table 1.

[0024] The commercial...

Embodiment 2

[0026] Weigh 1.0g of the main slurry epoxy resin, 0.26g of the mixed emulsifier Span40 and Tween 60, and 141.6g of deionized water, wherein the mass ratio of the mixed emulsifier Span40 and Tween 60 is 3:7, and the HLB value is 12.44. Add the main slurry and emulsifier together into deionized water, control the system temperature to 70°C, and stir at a high speed for 70 minutes with an emulsifier at a speed of 12,000 rpm, and cool to obtain an epoxy resin emulsion. 0.86 g of carboxylated multi-walled carbon nanotubes with a length of 3 μm and 1.07 g of polyethylene glycol 10000 were added to the epoxy resin emulsion. After mixing evenly, sonicate for 2 hours, and then stir for 12 hours at a rotational speed of 600 rpm to obtain an emulsion-type carbon fiber sizing agent containing carbon nanotubes. The mass fraction of each component in the sizing agent is shown in Table 1.

[0027] The commercial T300 carbon fiber was extracted with acetone for 5 hours to remove the size, and...

Embodiment 3

[0029] Weigh 1.0g of the main slurry epoxy resin, 0.25g of the mixed emulsifier Span80 and Tween 40, and 98.75g of deionized water, wherein the mass ratio of the mixed emulsifier Span80 and Tween 40 is 2:3, and the HLB value is 11.08. Add the main slurry and emulsifier into deionized water, control the temperature of the system at 80°C, and stir at a high speed for 40 minutes with an emulsifier at a speed of 10,000 rpm, and cool to obtain an epoxy resin emulsion. 0.75 g of carboxylated multi-walled carbon nanotubes with a length of 5 μm and 1.0 g of polyethylene glycol 4000 were added to the epoxy resin emulsion. After mixing evenly, sonicate for 1 h, and then stir at 700 rpm for 10 h to obtain an emulsion-type carbon fiber sizing agent containing carbon nanotubes. The mass fraction of each component in the sizing agent is shown in Table 1.

[0030] The commercial T700 carbon fiber was extracted with acetone for 6 hours to remove the size, and then the sizing agent was used to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com