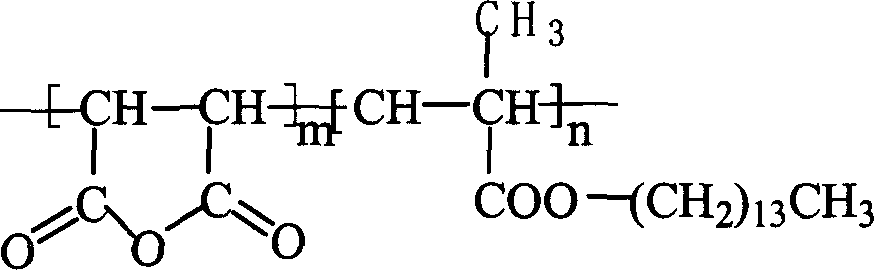

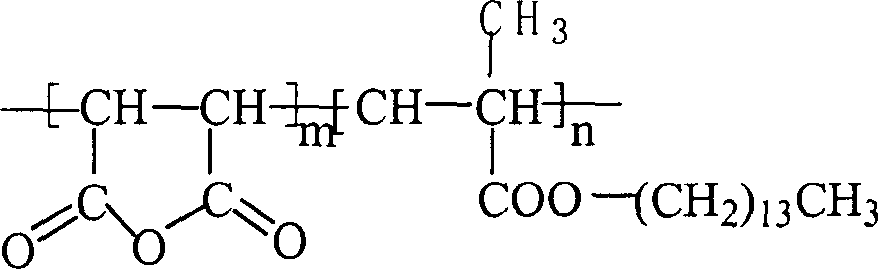

Use of methacrylic acid tetradecyl ester-maleic anhydride copolymer

A technology of maleic anhydride and methacrylic acid, which is applied in the field of macromolecular interface modifiers, can solve the problems of no improvement in the impact strength of composite materials, low grafting rate and conversion rate, and increased toughness of composite materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The polymerization reaction was carried out in a four-necked round-bottomed flask, which was connected with a ventilation tube, a thermometer, and a stirrer, and heated in a water bath at a constant temperature of 60°C. Put in 300mL of solvent toluene, put in 60g of maleic anhydride, and start stirring after nitrogen protection for about 30 minutes. When the maleic anhydride was completely dissolved, 75 grams of tetradecyl methacrylate was added, and after the monomers were uniformly mixed, 0.15 grams of initiator AIBN toluene solution was added to initiate the reaction, and the mixture was continuously stirred for 6 hours in a nitrogen atmosphere. The reaction product was precipitated and filtered with methanol, and the obtained polymer product was redissolved in tetrahydrofuran, and methanol was precipitated again to remove impurities. The polymer product is vacuum-dried to constant weight, and the target product of the present invention is obtained.

[0030] The anh...

Embodiment 2

[0032] Using the same method as in Example 1, wherein: 75 grams of maleic anhydride was added, 94 grams of myristyl methacrylate was added, the reaction temperature was 50° C., and the reaction time was 8 hours.

[0033] The anhydride content is 44.2%.

Embodiment 3

[0035] Using the same method as in Example 1, wherein: 90 grams of maleic anhydride was added, and the stirring was started after nitrogen protection for about 30 minutes. After the maleic anhydride was completely dissolved, 65 grams of myristyl methacrylate was added, and the anhydride content was 42.1%. The reaction temperature was 70°C, and the reaction time was 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com