Polyether ketone ketone sizing agent and method thereof for sizing and preparing carbon fiber composite

A technology of polyether ketone ketone and carbon fiber, which is applied in the direction of carbon fiber, fiber treatment, fiber type, etc., can solve the problems of poor interface bonding performance, macroscopic mechanical properties of composite materials and poor interlayer bonding performance, etc., and achieve strong adhesion , excellent chemical resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The polyether ketone ketone sizing agent was prepared by weighing each raw material according to the following parts by weight: 0.1 part of low crystal polyether ketone ketone resin, 90 parts of sulfuric acid solution with a mass fraction of 98.3%, and 2 parts of graphene oxide with an average particle size of 5000 mesh. Mix and stir the above raw materials until the polyether ketone ketone dissolves completely in the sulfuric acid solution.

[0022] The CF-PEKK-GO composite material was prepared according to the following steps using the polyetherketoneketone sizing agent:

[0023] 1) Immerse the carbon fiber monofilament in the polyether ketone ketone sizing agent for 1 minute, then take it out and wash it with deionized water until the deionized water is neutral, that is, remove the sulfuric acid residue, dry it, and make the surface of the carbon fiber monofilament form PEKK-GO film;

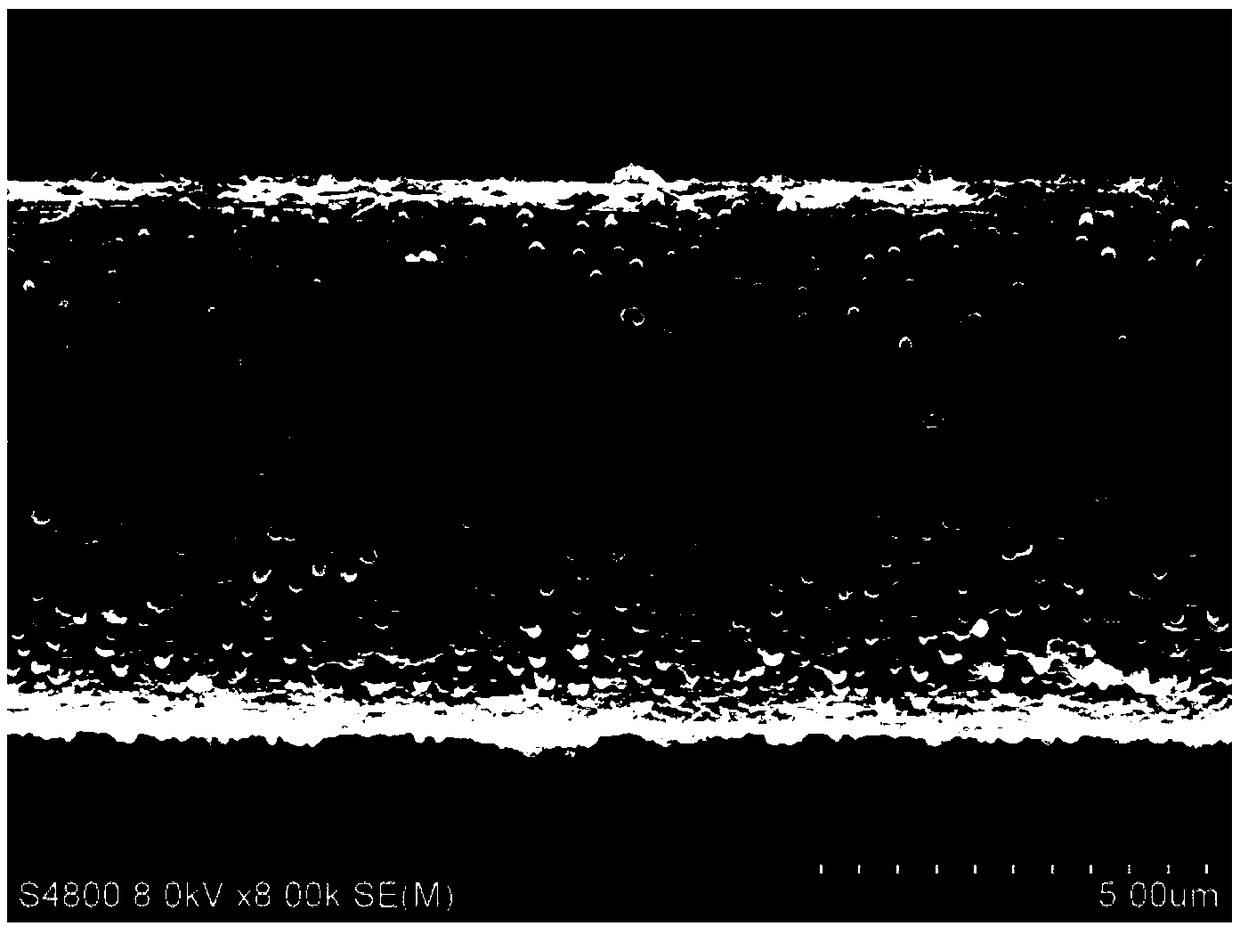

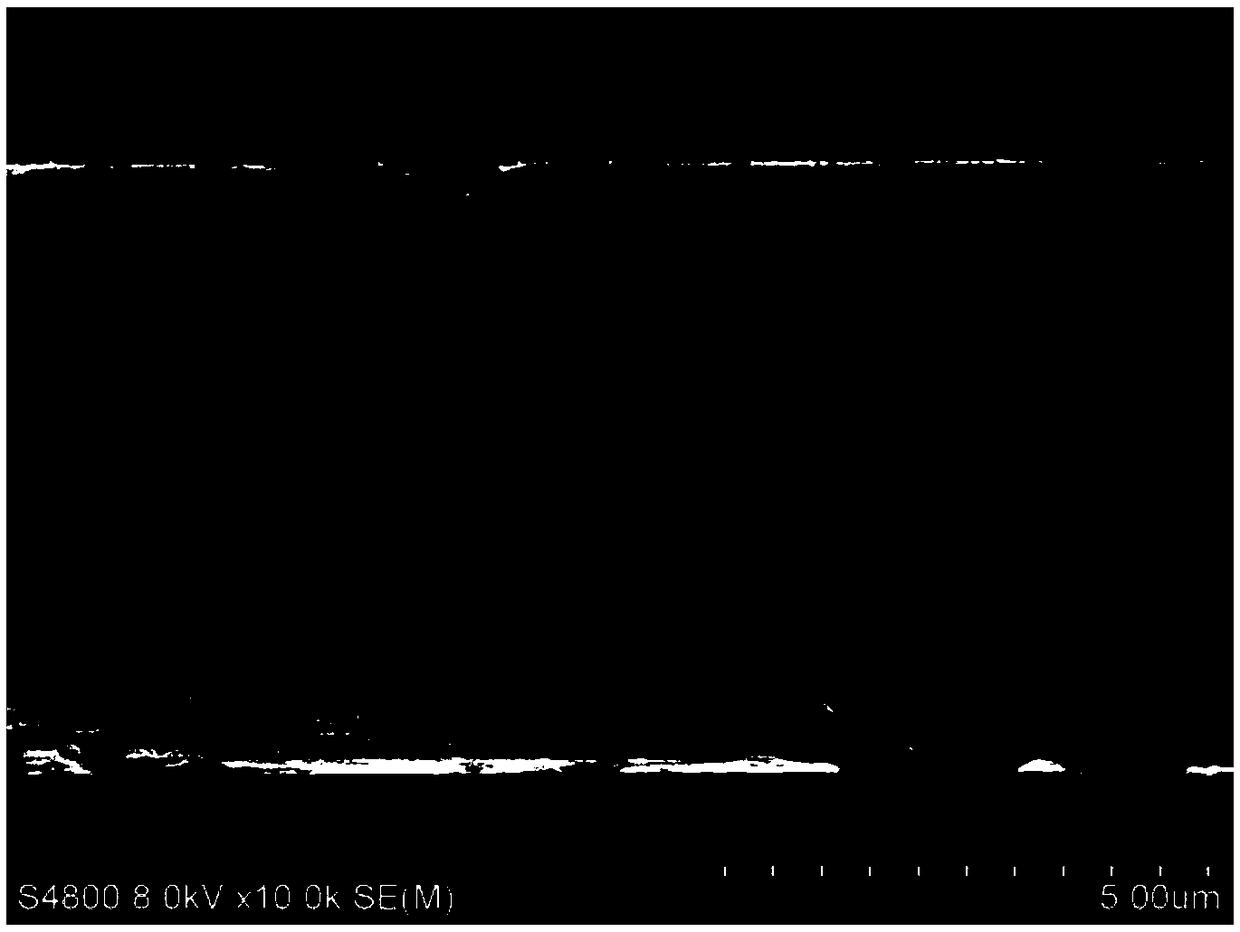

[0024] 2) if figure 1 As shown, after the surface of the carbon fiber monofilam...

Embodiment 2

[0026] The polyether ketone ketone sizing agent was prepared by weighing each raw material according to the following parts by weight: 5 parts of polyether ketone ketone resin, 50 parts of 90% sulfuric acid solution by mass fraction, and 0.1 part of graphene oxide with an average particle size of 300 mesh. Mix and stir the above raw materials until the polyether ketone ketone dissolves completely in the sulfuric acid solution.

[0027] The CF-PEKK-GO composite material was prepared according to the following steps using the polyetherketoneketone sizing agent:

[0028] 1) Immerse the carbon fiber monofilament in the polyether ketone ketone sizing agent for 20 minutes, then take it out and wash it with deionized water until the deionized water is neutral, and dry it to form a PEKK-GO film on the surface of the carbon fiber monofilament;

[0029] 2) After the surface of the carbon fiber monofilament treated in step 1) is electrostatically adsorbed to absorb a layer of polyether k...

Embodiment 3

[0031] The polyether ketone ketone sizing agent was prepared by weighing each raw material according to the following parts by weight: 3 parts of low crystal polyether ketone ketone resin, 20 parts of 98% sulfuric acid solution by mass fraction, and 0.1 part of graphene oxide with an average particle size of 5000 mesh. Mix and stir the above raw materials until the polyether ketone ketone dissolves completely in the sulfuric acid solution.

[0032] The CF-PEKK-GO composite material was prepared according to the following steps using the polyetherketoneketone sizing agent:

[0033] 1) Immerse the carbon fiber monofilament in the polyether ketone ketone sizing agent for 10 minutes, then take it out and wash it with deionized water until the deionized water is neutral, and dry it to form a PEKK-GO film on the surface of the carbon fiber monofilament;

[0034] 2) After the surface of the carbon fiber monofilament treated in step 1) is electrostatically adsorbed to absorb a layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com