Preparation method of nanometer zinc oxide modified aramid fiber

A nano-zinc oxide and modified aramid fiber technology, applied in the field of aramid fiber, can solve the problems that have not been seen before, and achieve the effects of improved interfacial shear strength, improved bonding fastness and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

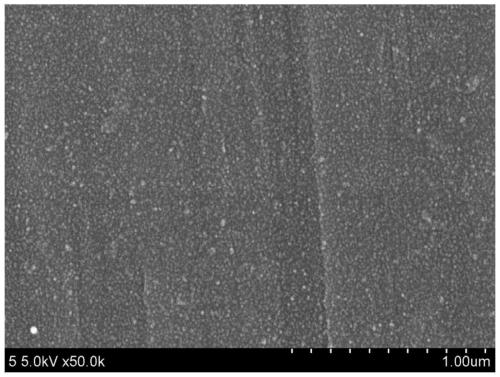

[0034] This embodiment provides a method for preparing nano-zinc oxide modified aramid fibers, and the specific preparation steps are as follows:

[0035] Step 1: Functional treatment of aramid fiber:

[0036] a. Preparation of hydrolyzed aramid fibers: firstly, aramid fibers (heterocyclic aramid F-368, Zhonglan Chenguang Chemical Research Institute) were wound on a polytetrafluoroethylene square frame, and then immersed in a concentration of 10wt% sodium hydroxide In the solution, treat it at a temperature of 30°C and a stirring speed of 100r / min for 10 minutes, rinse it with deionized water three times; immerse the fiber treated with sodium hydroxide in 10% hydrochloric acid for 30s, and rinse it with deionized water 3 times, followed by vacuum drying in an oven at 120°C for 1 hour to obtain hydrolyzed aramid fiber;

[0037] b. Functional treatment of aramid fibers: Put the above-mentioned hydrolyzed aramid fibers into a mixture of thionyl chloride and N,N-dimethylformamide...

Embodiment 2

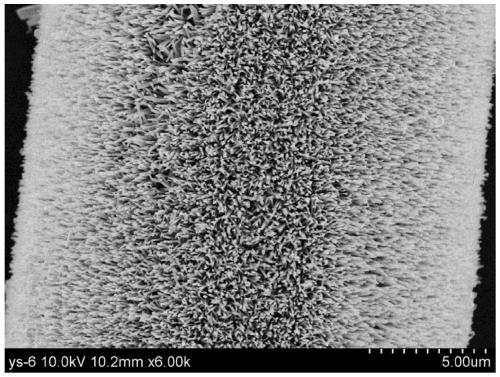

[0053] This embodiment provides a method for preparing nano-zinc oxide modified aramid fibers, and the specific preparation steps are as follows:

[0054] Step 1: Functional treatment of aramid fiber:

[0055] a. Preparation of hydrolyzed aramid fiber: firstly wind the aramid fiber (heterocyclic aramid F-368, Zhonglan Chenguang Chemical Research Institute) on a polytetrafluoroethylene square frame, and then immerse it in a concentration of 20wt% sodium hydroxide In the solution, treat it at a temperature of 40°C and a stirring speed of 150r / min for 20 minutes, rinse it with deionized water three times; immerse the fiber treated with sodium hydroxide in 20% hydrochloric acid for 40s, and rinse it with deionized water 3 times, followed by vacuum drying in an oven at 120°C for 1 hour to obtain hydrolyzed aramid fibers;

[0056] b. Functional treatment of aramid fibers: put the above-mentioned hydrolyzed aramid fibers into a mixture of thionyl chloride and N,N-dimethylformamide w...

Embodiment 3

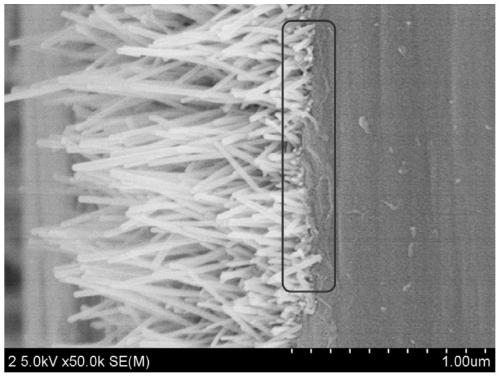

[0072] This embodiment provides a method for preparing nano-zinc oxide modified aramid fibers, and the specific preparation steps are as follows:

[0073] Step 1: Functional treatment of aramid fiber:

[0074] a. Preparation of hydrolyzed aramid fiber: firstly, the aramid fiber (heterocyclic aramid F-368, Zhonglan Chenguang Chemical Research Institute) is wound on a polytetrafluoroethylene square frame, and then immersed in a concentration of 30wt% sodium hydroxide In the solution, treat it at a temperature of 50°C and a stirring speed of 200r / min for 30min, rinse it with deionized water for 4 times; immerse the fiber treated with sodium hydroxide in 30% hydrochloric acid for 30s, rinse it with deionized water 4 times, followed by vacuum drying in an oven at 120°C for 1 hour to obtain hydrolyzed aramid fibers;

[0075] b. Functional treatment of aramid fiber: Put the above-mentioned hydrolyzed aramid fiber into a mixture of thionyl chloride and N,N-dimethylformamide with a vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com