Full-automatic PTFE film/fiber stretching and sintering machine and stretching and sintering method

A PTFE, fully automatic technology, applied in the field of textile equipment, can solve problems such as PTFE film/fiber breakage, and achieve the effect of avoiding scalding, continuous production, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

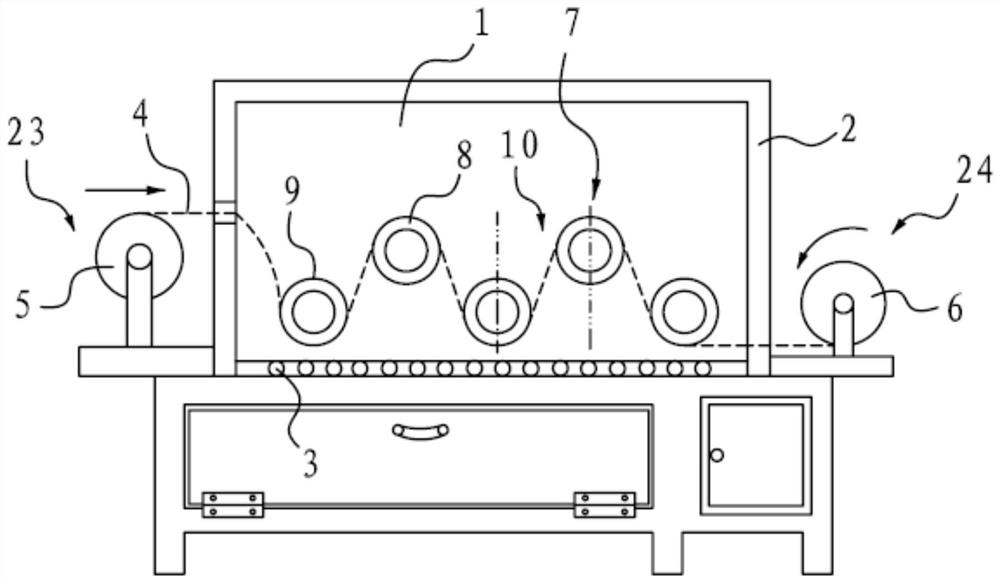

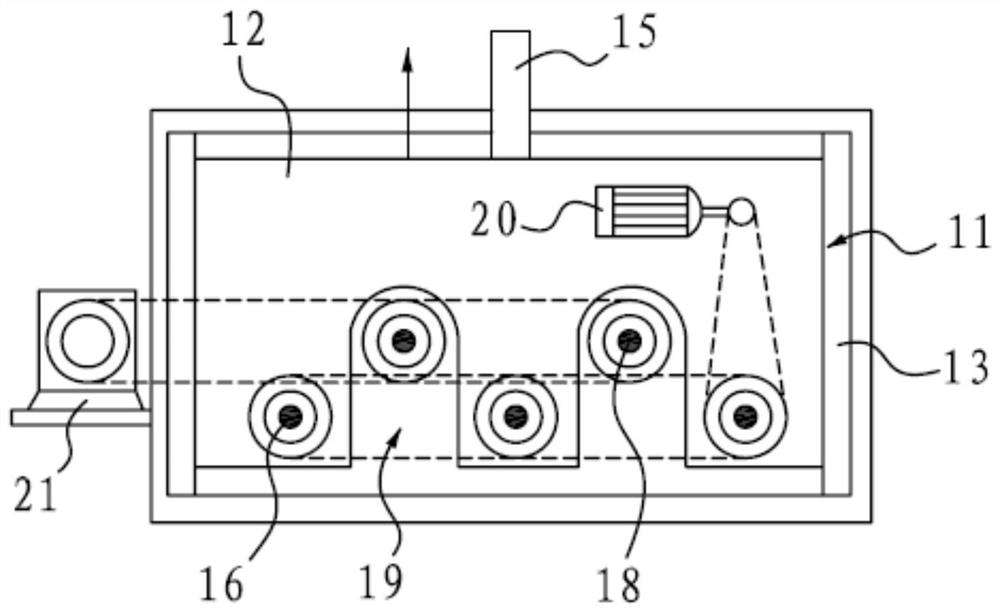

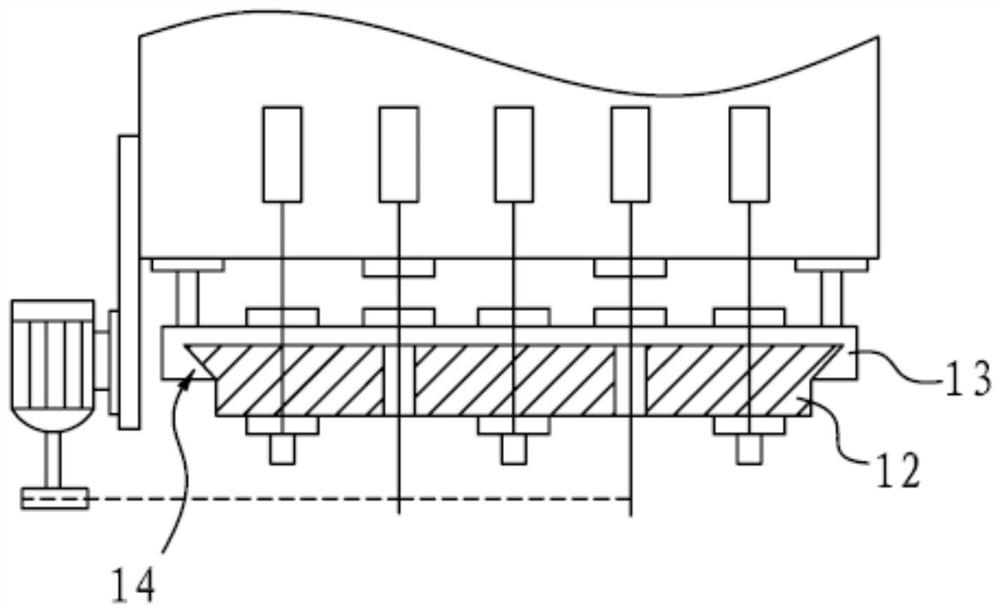

[0040] Such as figure 1 , 2 , 3, 4, and 5, a full-automatic PTFE film / fiber stretching sintering machine includes a casing 2 with a sealed stretching sintering chamber 1, and one for stretching and sintering in the stretching sintering chamber 1. The heated temperature control part 3, the temperature control part 3 can adopt electric heating tubes or other electric heating elements commonly used at present, and the working temperature environment in the stretching sintering chamber 1 is 220-240°C. A door body for sealing the stretch sintering chamber 1 is provided on the box body 2 , and the door body is not shown in the accompanying drawings in order to clearly illustrate the technical solution of the present application. One side of the box body 2 is provided with an unwinding device 5 for conveying the PTFE film / fiber 4 into the stretching sintering chamber 1, and the other side is provided with a winding device 5 for stretching and sintering the PTFE film / fiber 4 after se...

Embodiment 2

[0053] The same parts of this embodiment and Embodiment 1 will not be repeated. The difference is that in order to realize the automatic operation of the equipment, this embodiment adopts a fully automatic signal control mode. Specifically, the broken end connection system includes a controller. Either side of the unwinding device 5 or the winding device 6 is provided with a detection element for detecting a tension change when the PTFE film / fiber 4 breaks, and the detection element detects a tension change and sends a detection signal to the controller, and the controller After receiving the detection signal, send the signal for driving the stretching roller assembly 7 to stop rotating to the power mechanism, and send the signal for driving the lower stretching roller 9 to rise to the second power mechanism 15, and send the signal for driving the clamping and pulling Pull the broken PTFE film / fiber 4 from the unwinding end 23 through the upper stretching roller 8 and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com