Continuous automatic production device of vibration damping plate and production method

A production device and production method technology, which is applied in the fields of architectural decoration, automobiles, and home appliance materials, and can solve the problems of large amount of misalignment, unstable performance, and low peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

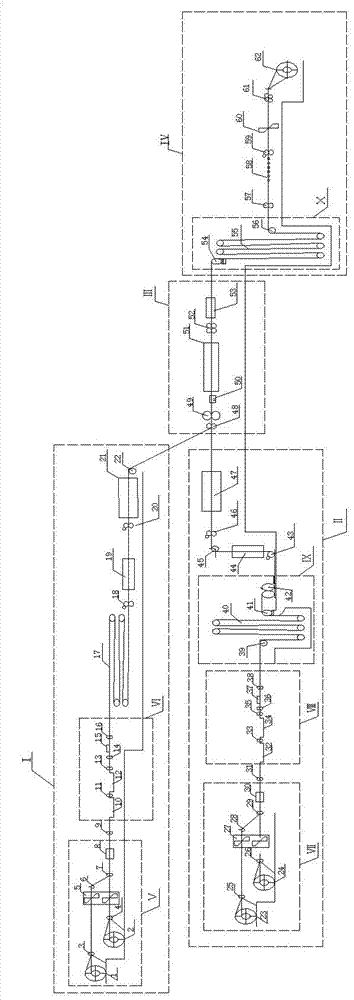

[0039] like figure 1 As shown, a continuous automatic production device for vibration damping plates includes an upper steel plate processing unit I, a lower steel plate processing unit II, a composite unit III, and a post-processing unit IV.

[0040] The upper layer steel plate processing unit I includes the upper layer steel plate continuous uncoiling device V, the upper layer steel plate first pinch roll 9, the upper layer steel plate degreasing tank 10, the upper layer steel plate fourth pinch roll 11, the upper layer steel plate cleaning Groove 12, the fifth pinch roller 13 of the upper steel plate, the squeeze roller 14 of the upper steel plate, the air dryer 15 of the upper steel plate, the sixth pinch roller 16 of the upper steel plate, the looper of the entrance section of the upper steel plate 17, the chemical coating machine of the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com