Novel process for welding copper strip and aluminum strip

A welding process, a new type of copper strip technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as continuous production of production lines, achieve reasonable operation, low manufacturing costs, and improve connection strength and process. controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

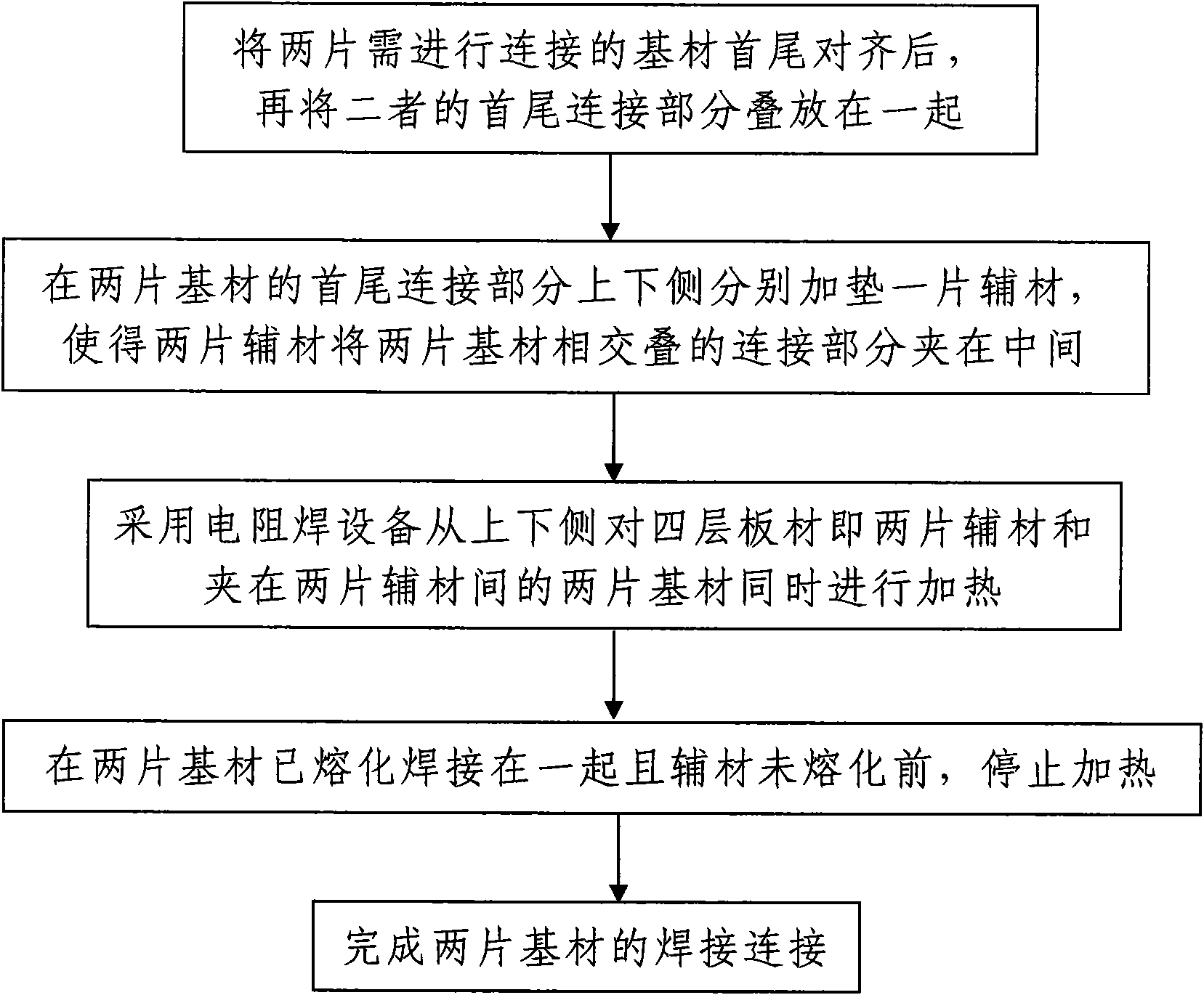

Method used

Image

Examples

Embodiment 1

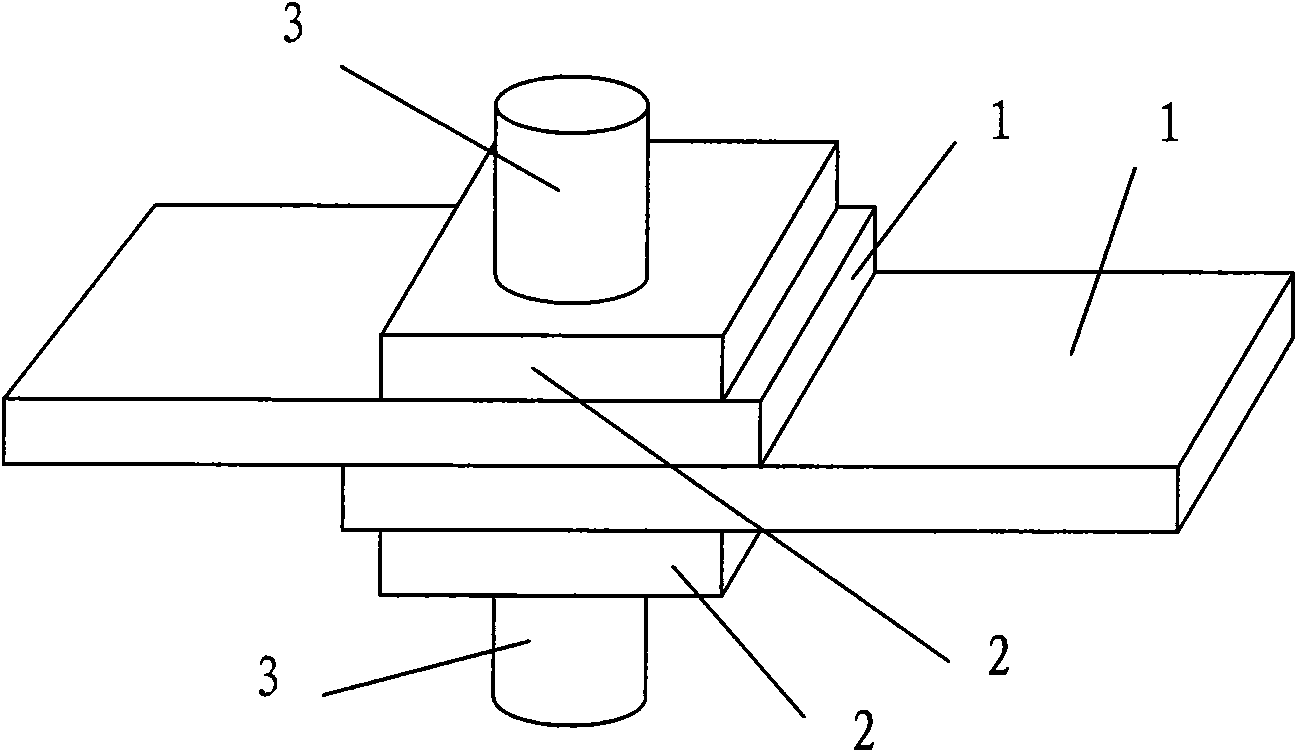

[0029] In this embodiment, the base material 1 is a copper strip with a thickness of 1.2 mm. When stacking the two base materials 1 after aligning their ends, it is necessary to ensure that the ends of the two base materials 1 are always aligned. The end-to-end connection part of the two substrates 1 is the part where the two substrates 1 are connected after being welded and fixed, that is, the part where the two substrates 1 are stacked end to end in this step. If necessary, the length of the head-to-tail connection part of the two substrates 1 is adjusted, generally for the purpose of saving materials, and the shorter the length of this part, the better, usually 5mm-30mm. The thickness of the auxiliary material 2 is the same as that of the base material 1, that is, the thickness of the auxiliary material 2 is 1.2 mm, and the auxiliary material 2 is low carbon steel. After aligning the two pieces of copper strips to be welded head to tail and stacking the head and tail connec...

Embodiment 2

[0031] In this embodiment, the difference from Embodiment 1 is that the thickness of the copper strip is 0.01 mm, the thickness of the low carbon steel plate is 0.05 mm, and the rest of the welding steps and process conditions are the same as in Embodiment 1.

Embodiment 3

[0033] In this example, the difference from Example 1 is that the thickness of the copper strip is 0.02 mm, the thickness of the low carbon steel plate is 0.05 mm, and the rest of the welding steps and process conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com