A jet arch for continuous fluidized reactor and aerodynamic fluidization reactor

A technology of jet arch and reactor, which is applied in the field of jet arch and fluidization reactor, can solve the problems of insufficient power, clogging of slag discharge holes, burnout of burner, etc., and achieve the effect of full combustion and avoid clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

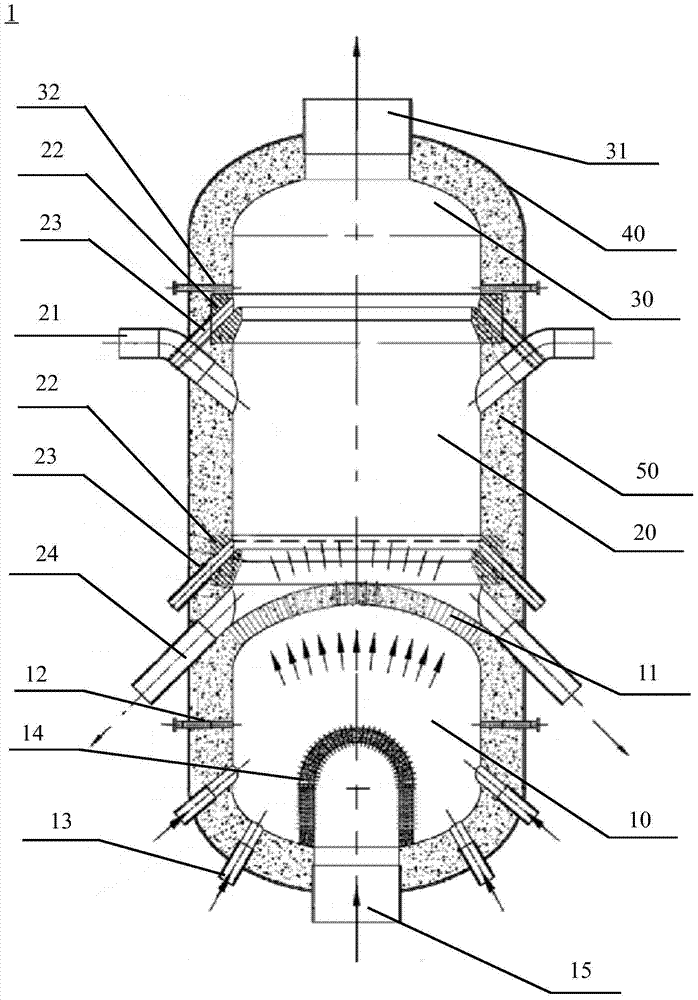

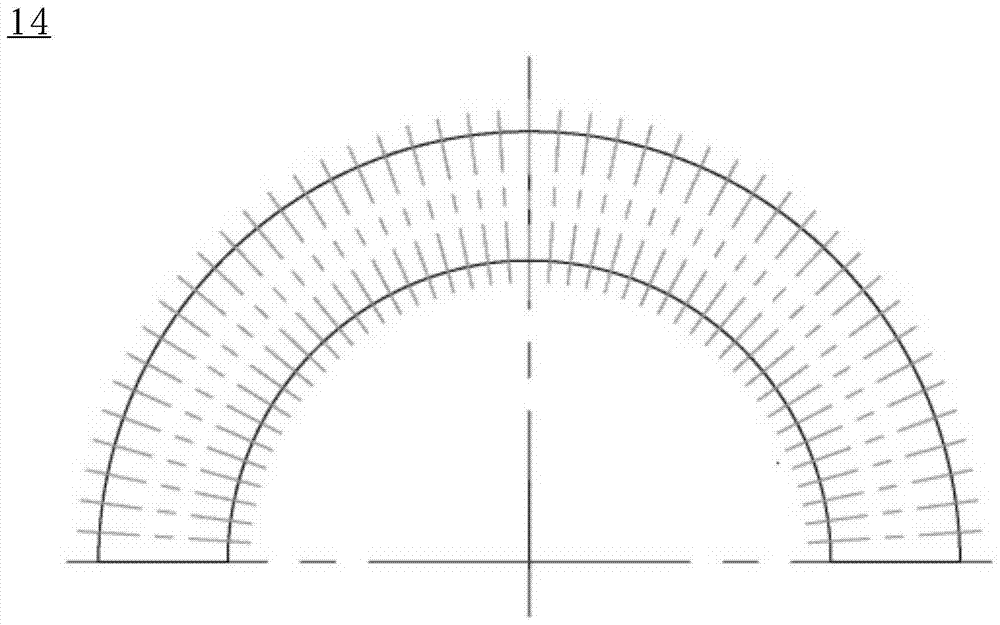

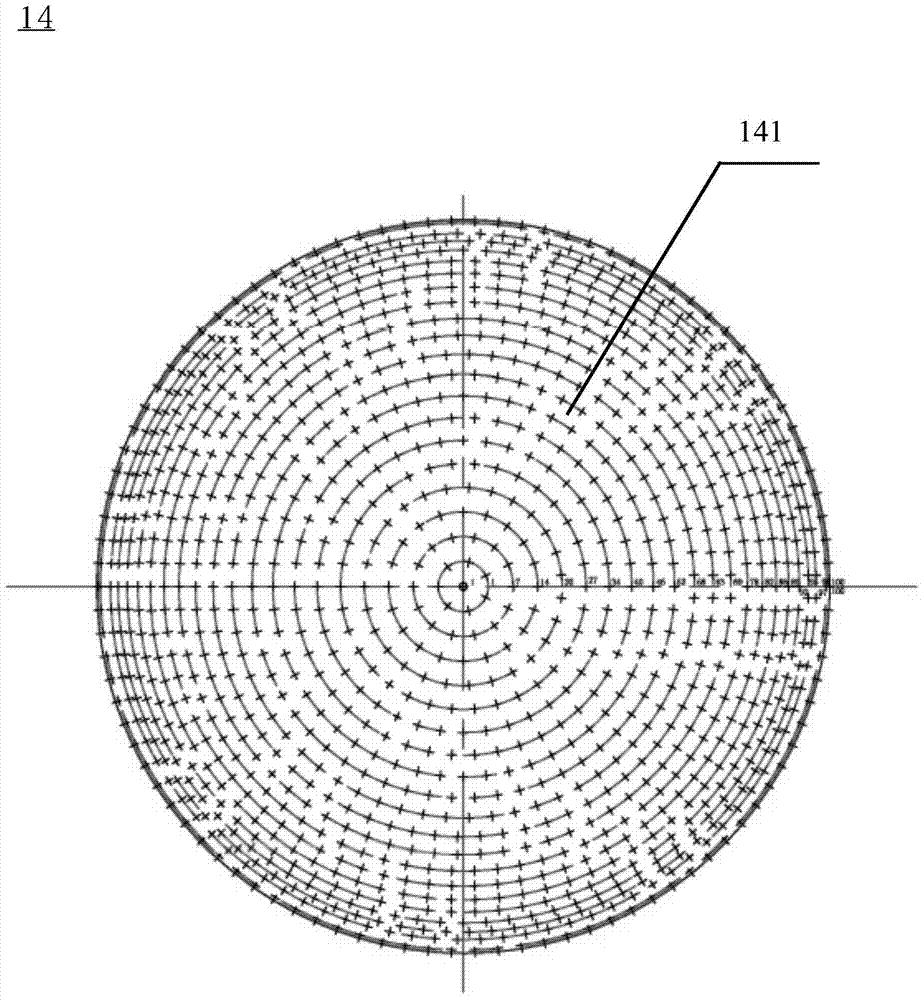

[0041] A detailed description will be given below in conjunction with the accompanying drawings. The jet arch and the gas-generating fluidization reactor involved in the present invention are specifically illustrated by taking the fluidized reactor for preparing phosphorus pentoxide as an example, but it is not intended to limit the present invention, and the jet arch and the gas-generating fluidization reactor of the present invention can also be For the preparation of any other solid fluidized substances, as long as those skilled in the art can think of.

[0042] P of the present invention 2 o 5 The gasification reactor is suitable for the production of phosphoric acid from medium and low-grade phosphate rock. The materials (raw materials) entering the reactor need to go through the refining process in advance. The specific steps of the smelting process are as follows: crush and sieve the collected medium and low-grade phosphate rock (containing 17-22% phosphorus), so tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com