Preparation method of composite nanostructure catalyst based on nickel substrate in-situ etching growth

A composite nanostructure, in-situ etching technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of reducing catalyst stability, bubble damage, etc., to achieve enhanced chemical stability, slow down corrosion, and facilitate repulsion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

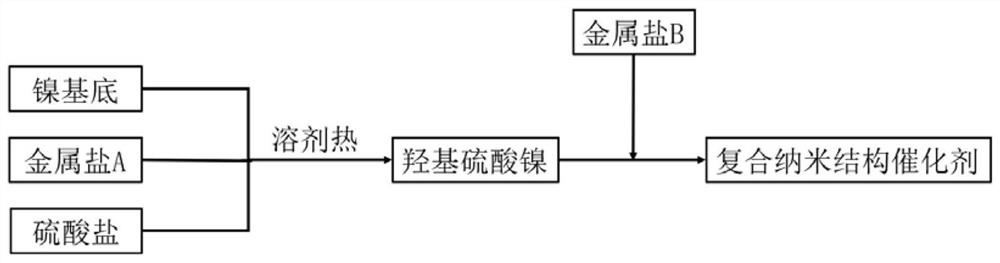

[0034] A kind of preparation method of composite nanostructure catalyst based on in-situ etching growth of nickel substrate, see figure 1 , the operation steps are as follows:

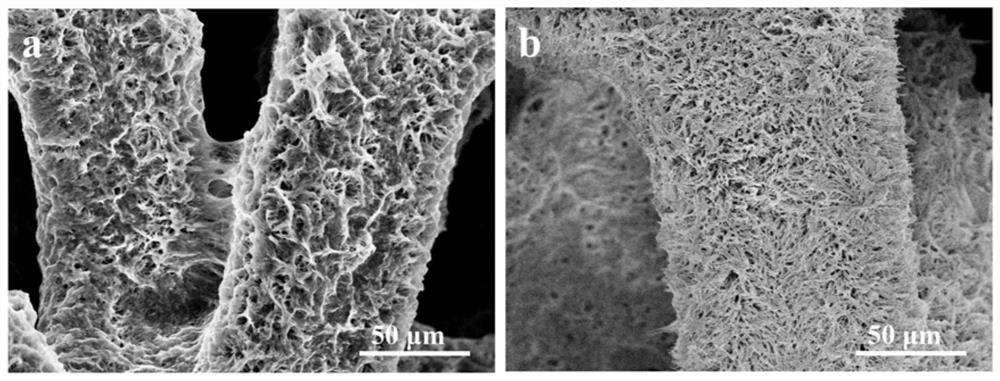

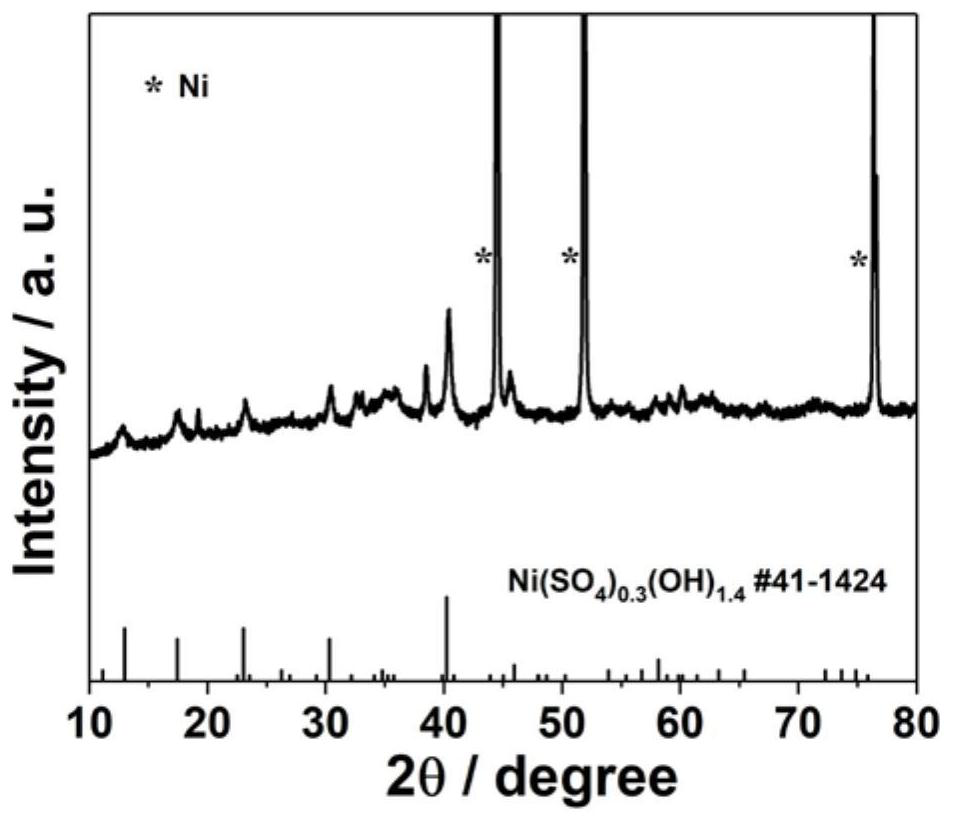

[0035] (1) Preparation of nickel hydroxysulfate: a piece of nickel foam (1*2 square centimeters) is placed flat in a 50 milliliter Teflon-lined stainless steel autoclave, and then added to 30 milliliters of aqueous solution containing 10 mmol per liters of nickel acetate and 50 millimoles per liter of sulfuric acid. Then heated to 140 degrees in a drying oven and kept at this temperature for 6 hours. Then naturally cool to room temperature to obtain green nickel hydroxysulfate, and find that there is no precipitation in the solution. Finally, ultrasonication in water for 15 minutes removes residual ions and unstable substances (see figure 2 a).

[0036] (2) Preparation of ferric hydroxide-nickel hydroxysulfate: the sample obtained in step (1) was placed in a beaker, and 20 milliliters of aqueous s...

Embodiment 2

[0039] A method for preparing a composite nanostructure catalyst based on in-situ etching and growth of a nickel substrate, the operation steps are as follows:

[0040] (1) Preparation of nickel hydroxysulfate: a piece of nickel foam (1*2 square centimeters) is placed flat in a 50 milliliter Teflon-lined stainless steel autoclave, and then added to 30 milliliters of aqueous solution containing 500 millimoles per liter of nickel sulfate and 10 mmol per liter of ammonium sulfate. It was then heated to 120°C in a drying oven and kept at this temperature for 24 hours. Then naturally cool to room temperature to obtain green nickel hydroxysulfate, and find that there is no precipitation in the solution. Finally, ultrasonication in water for 15 minutes removes residual ions and unstable substances.

[0041] (2) Preparation of ferric hydroxide-nickel hydroxysulfate: the sample obtained in step (1) was placed in a beaker, and 20 milliliters of aqueous solution was added, which contai...

Embodiment 3

[0043] A method for preparing a composite nanostructure catalyst based on in-situ etching and growth of a nickel substrate, the operation steps are as follows:

[0044] (1) Preparation of nickel hydroxysulfate: a piece of nickel foam (1*2 square centimeters) is placed flat in a 50 milliliter Teflon-lined stainless steel autoclave, and then added to 30 milliliters of aqueous solution containing 200 millimoles per liter of nickel chloride and 500 millimoles of magnesium sulfate per liter. It was then heated to 130°C in a drying oven and kept at this temperature for 12 hours. Then naturally cool to room temperature to obtain green nickel hydroxysulfate, and find that there is no precipitation in the solution. Finally, ultrasonication in water for 15 minutes removes residual ions and unstable substances.

[0045] (2) Preparation of ruthenium hydroxide-nickel hydroxysulfate: the sample obtained in step (1) was placed in a beaker, and 20 milliliters of aqueous solution was added, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com