Liquid classifier for colloid mill

A classifier and colloid mill technology, applied in the direction of separating solids from solids with airflow, solid separation, application, etc., can solve the problems of product quality decline, continuous production, and no classifier configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

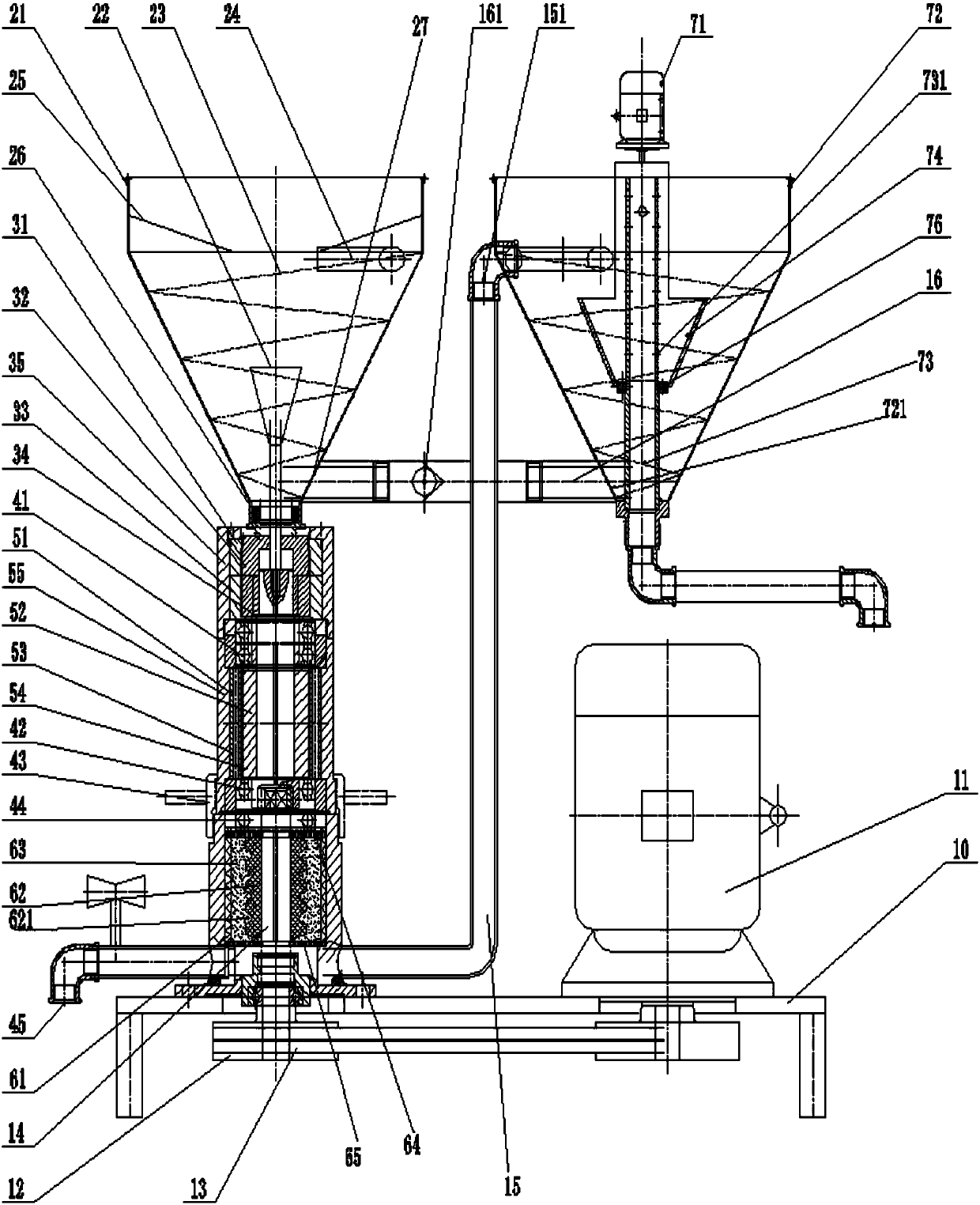

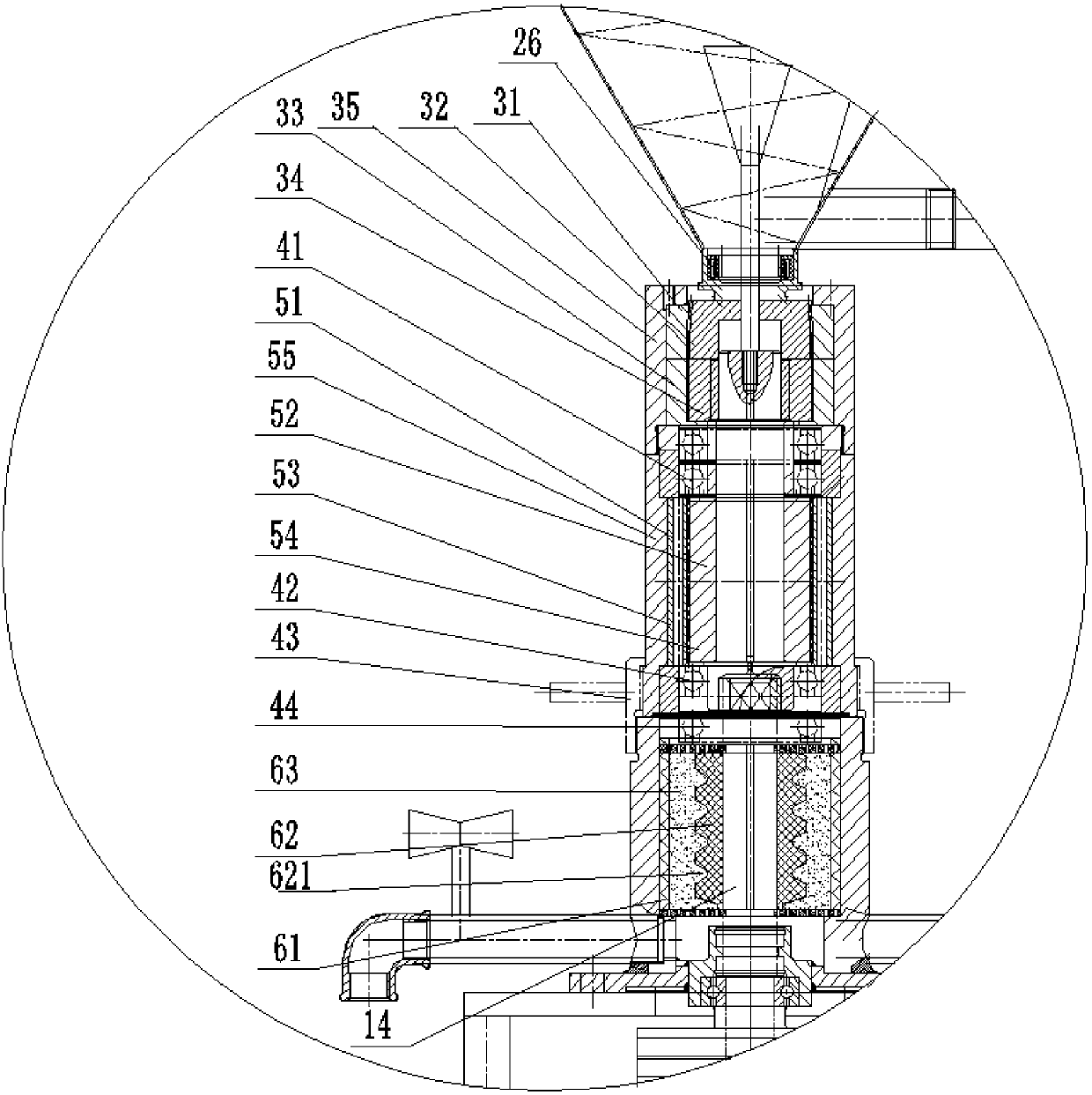

[0019] see figure 1 and 2 , the invention discloses an ultramicro colloid mill device, comprising a base 10 and a driving mechanism arranged on the base 10, a colloid mill grinding mechanism, a funnel, a liquid classifier for the colloid mill, a classification connecting pipe 15 and a return Research Pipeline16. The funnel is arranged above the grinding mechanism, the driving mechanism can transmit power to the grinding mechanism, and the liquid classifier for the colloid mill is respectively connected with the funnel and the grinding mechanism of the colloid mill. The discharge port of the funnel is connected with the feed port of the colloid mill grinding mechanism, the discharge port of the colloid mill grinding mechanism is connected with one end of the classification connection pipe 15, and the other end of the classification connection pipe 15 is It is connected to the liquid classifier for colloid mill, and the two ends of the back-grinding pipeline 16 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com