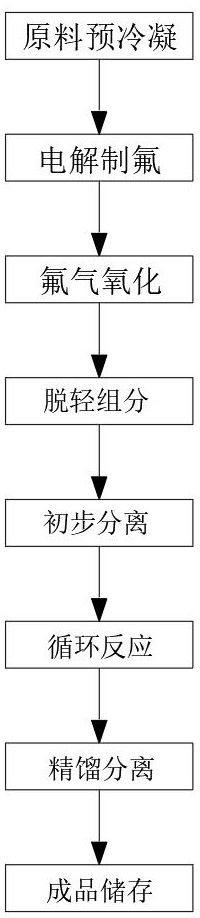

Purification process of high-purity anhydrous hydrogen fluoride

An anhydrous hydrogen fluoride, high-purity technology, applied in the direction of hydrogen fluoride, fluorine/hydrogen fluoride, etc., can solve the problems of non-continuous industrial production, high impurity content of waste acid, low utilization value, etc., achieve low production cost, improve purity, and equipment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

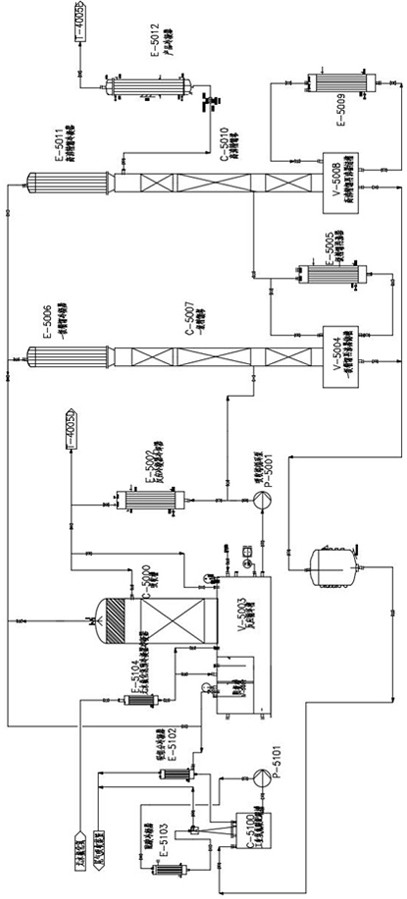

[0048] First, the raw material industrial grade HF is cooled to about 10°C in the pre-cooler E-5104 to ensure that the medium entering the reactor is in the liquid phase, and the feed rate is 2500kg / h.

[0049] Then use the principle of electrolytic fluorine production to control the fluorine gas produced by the electrolysis voltage (8-10V), and control the amount of industrial anhydrous hydrogen fluoride in the electrolysis tank through the liquid level of the electrolysis tank. The amount of fluorine gas produced depends on the electrolysis current and electrolysis time. Controlled, the fluorine gas generated in the anode chamber enters the hydrogen fluoride absorption tower through the channel, and oxidizes a small amount of impurities in anhydrous hydrogen fluoride to form light and heavy components that are easy to separate; the fluorine-containing hydrogen gas generated in the cathode cell is connected to the E-5102 for cooling through the negative pressure pipe Recover a...

Embodiment 2

[0057] The process conditions and equipment are the same as in Example 1, except that the circulation rate of the fluorine oxidation reaction is 15000 kg / h, and the feed rate of the fluorine gas is 0.5g / per 1kgHF. In order to prevent the accumulation of impurities, the The still draws 70kg / h material and enters in the V-5100, and other conditions are the same as embodiment 1.

Embodiment 3

[0059] The process conditions and equipment are the same as in Example 1, except that the circulation rate of the fluorine oxidation reaction is 15000 kg / h, the feed rate of the fluorine gas is 1.5g / per 1kgHF, and 70kg / h is drawn from the high boiling rectification tower still h, the material enters into V-5100, and other conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com