Preparation method for heat-insulating type compact silicon brick

A silica brick and dense technology, applied in the field of refractory materials, can solve the problems of poor heat insulation effect and large volume of silica brick, and achieve the effect of promoting space gap, improving reactivity and increasing heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

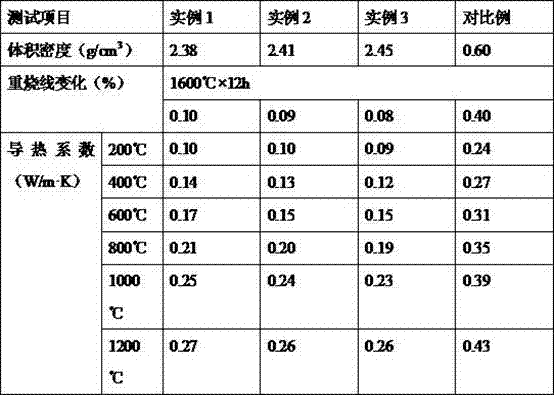

example 1

[0025] According to the mass ratio of 2:1, mix and grind basalt and dolomite for 1 hour, pass through a 50-mesh sieve, collect the sieved powder, put the sifted powder into a muffle furnace at 1500 ° C for 1 hour, and then pour it into a porous drain plate The self-made rock wool fiber was obtained by medium drawing for 30 minutes, and 8 g of phenolic resin, 30 mL of ammonia water with a concentration of 8 mol / L and 15 mL of deionized water were mixed and stirred for 10 min to obtain a self-made rock wool binder, which was mixed in a mass ratio of 2:1:1. After mixing and stirring the self-made rock wool binder, rapeseed oil and polysiloxane for 8 minutes, it becomes the self-made mixture. Spray a layer of self-made mixture with a thickness of 0.5mm on the surface of the above-mentioned self-made rock wool fiber. After collecting by machine for 1 hour, discharge the material and dry naturally to obtain self-made rock wool. Mix ethyl orthosilicate, hydrochloric acid with a concen...

example 2

[0027]According to the mass ratio of 2:1, mix and grind basalt and dolomite for 1.5 hours, pass through a 50-mesh sieve, collect the sieved powder, put the sieved powder into a muffle furnace at 1600 ° C for 1.5 hours, and then pour it into the porous Draw wire in the bushing for 40 minutes to obtain self-made rock wool fiber. Mix and stir 9g of phenolic resin, 40mL of ammonia water with a concentration of 8mol / L and 17mL of deionized water for 11min to obtain self-made rock wool binder. The mass ratio is 2:1: 1 After mixing and stirring the self-made rock wool binder, rapeseed oil and polysiloxane for 9 minutes, it is the self-made mixture. Spray a layer of self-made mixture with a thickness of 0.6mm on the surface of the above-mentioned self-made rock wool fiber. After spraying, pass After the cotton collector collects for 1.5 hours, the material is discharged and dried naturally to obtain self-made rock wool. The volume ratio is 3:1:2:1, and tetraethyl orthosilicate, hydroch...

example 3

[0029] According to the mass ratio of 2:1, mix and grind basalt and dolomite for 2 hours, pass through a 50-mesh sieve, collect the sieved powder, put the sifted powder into a muffle furnace at 1700 ° C for 2 hours, and then pour it into a porous drain plate The self-made rock wool fiber was obtained by medium drawing for 50 minutes, and 10 g of phenolic resin, 50 mL of ammonia water with a concentration of 8 mol / L and 20 mL of deionized water were mixed and stirred for 12 minutes to obtain a self-made rock wool binder, and the mass ratio was 2:1:1. After mixing and stirring the self-made rock wool binder, rapeseed oil and polysiloxane for 10 minutes, it becomes the self-made mixture. Spray a layer of self-made mixture with a thickness of 0.7mm on the surface of the above-mentioned self-made rock wool fiber. After collecting by the machine for 2 hours, discharge the material and dry naturally to obtain self-made rock wool. Mix ethyl orthosilicate, hydrochloric acid with a conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com