Primary alkaline battery negative electrode material and preparation method thereof

A technology for alkaline batteries and negative electrode materials, applied in battery electrodes, aqueous electrolyte batteries, nanotechnology for materials and surface science, etc., can solve the problem of few applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

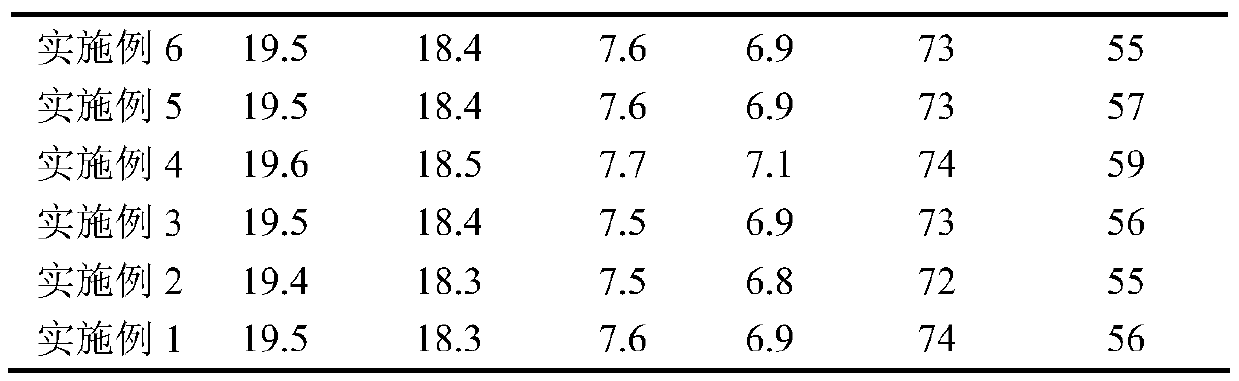

Embodiment 1

[0023] The invention provides a negative electrode material for a primary alkaline battery, comprising the following components in parts by weight:

[0024] 90 parts of zinc, wherein 0.92 part and 0.09 part of yttrium oxide (0.1% relative to the total amount of zinc) form a core-shell nanomaterial, the remaining zinc is a nanoscale material, 0.5 part of polyacrylic acid, and 1.5 parts of sodium polyacrylate.

[0025] The present invention also provides a kind of preparation method of above-mentioned primary alkaline battery negative electrode material, comprises the steps:

[0026] S1, prepare yttrium nitrate to 0.2mol L -1 Add 5% hydrogen peroxide dropwise (the molar ratio of yttrium nitrate to hydrogen peroxide is 2:4), stir and add 3% ammonia water dropwise until the pH of the solution is greater than 9, centrifuge at 13000 / min for 7min, take the precipitate and wash it with water after ultrasonication for 10min, 150 °C vacuum drying to obtain nanometer yttrium oxide;

[...

Embodiment 2

[0030] The invention provides a negative electrode material for a primary alkaline battery, comprising the following components in parts by weight:

[0031] 98 parts of zinc, wherein 0.95 part and 0.0784 part of yttrium oxide (0.08% relative to the total amount of zinc) form a core-shell nanomaterial, the remaining zinc is a nanoscale material, 1 part of polyacrylic acid, and 5 parts of sodium polyacrylate.

[0032] The present invention also provides a kind of preparation method of above-mentioned primary alkaline battery negative electrode material, comprises the steps:

[0033] S1, prepare yttrium nitrate to 0.2mol L -1 Add 7% hydrogen peroxide dropwise (the molar ratio of yttrium nitrate to hydrogen peroxide is 2:6), stir and add 6% ammonia water dropwise until the pH of the solution is greater than 9, centrifuge at 13000 / min for 9min, take the precipitate and wash it with water after ultrasonication for 20min, 180 °C vacuum drying to obtain nanometer yttrium oxide;

[0...

Embodiment 3

[0037] The invention provides a negative electrode material for a primary alkaline battery, comprising the following components in parts by weight:

[0038] 94 parts of zinc, wherein 0.96 part and 0.0672 part of yttrium oxide (0.07% relative to the total amount of zinc) form a core-shell nanomaterial, the remaining zinc is a nanoscale material, 0.5 part of polyacrylic acid, and 2 parts of sodium polyacrylate.

[0039] The present invention also provides a kind of preparation method of above-mentioned primary alkaline battery negative electrode material, comprises the steps:

[0040] S1, prepare yttrium nitrate to 0.2mol L -1 Add 5% hydrogen peroxide dropwise (the molar ratio of yttrium nitrate to hydrogen peroxide is 2:4), stir and add 5% ammonia water dropwise until the pH of the solution is greater than 9, centrifuge at 13000 / min for 6min, take the precipitate and wash it with water after ultrasonication for 15min, 160 °C vacuum drying to obtain nanometer yttrium oxide;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com