A method for granulating cross-linked sodium hyaluronate gel

A technology of cross-linking hyaluronic acid and sodium hyaluronate, applied in the direction of raw material extrusion granulation, etc., can solve the problems affecting the yield, difficult to control the gel particle size and uniformity, etc., achieve uniform texture, improve The effect of granulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: As a filler for treating soft tissue injuries.

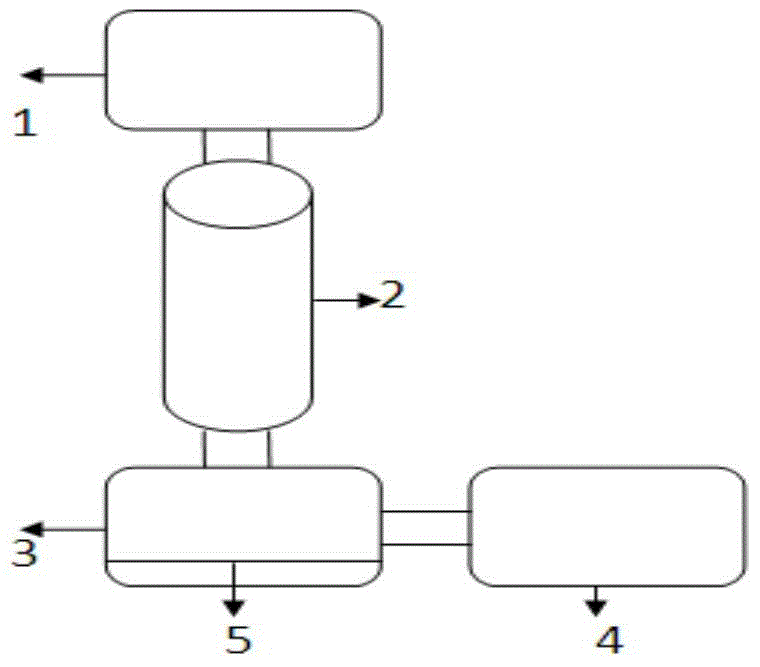

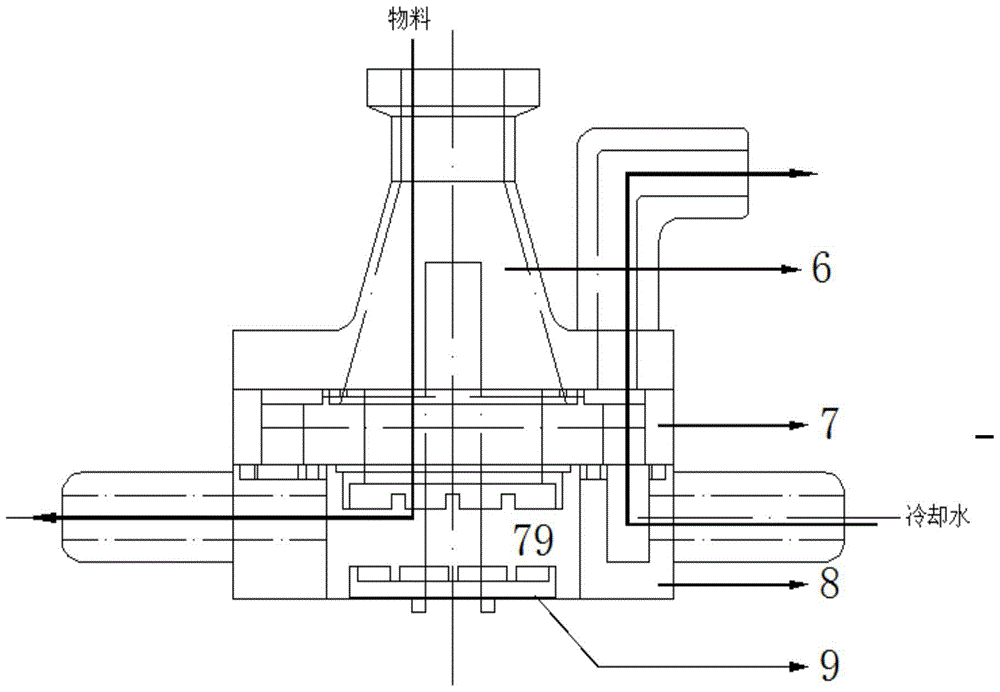

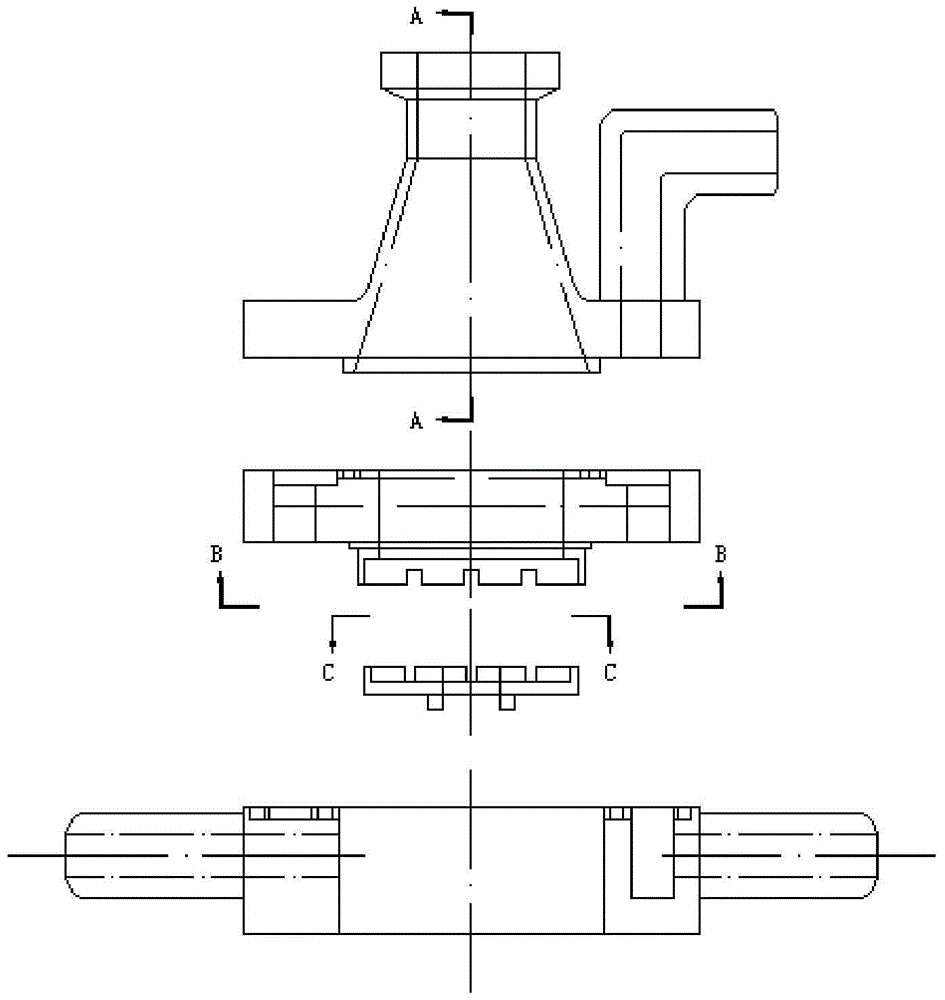

[0050] Select 1# stator and rotor combination, follow the attached figure 1 , 2 Perform the assembly of the granulating device. Start the cooling water circulation system, set the speed to 3000rpm, and run the split head. After the actual speed reaches the set parameters, pass in 0.04MPa compressed air.

Embodiment 2

[0051] Example 2: As a filler for treating stress urinary incontinence.

[0052] Select 1# stator and rotor combination, follow the attached figure 1 , 2 Perform the assembly of the granulating device. Start the cooling water circulation system, set the speed to 10000rpm, and run the split head. After the actual speed reaches the set parameters, pass in 0.04MPa compressed air.

Embodiment 3

[0053] Example 3: As a temporary particle embolization agent, to avoid accidental embolism caused by small particle embolization agent.

[0054] Select 1# stator and rotor combination, follow the attached figure 1 , 2 Perform the assembly of the granulating device. Start the cooling water circulation system, set the speed to 3000 rpm, and run the split head. After the actual speed reaches the set parameters, pass in 0.10 MPa compressed air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com