Method for effectively producing 1,3-propanediol by modifying permeability of cell membrane

A propylene glycol and permeability technology, applied in 1 field, can solve the problems of long production cycle, low bacterial volume, low production intensity, etc., and achieve the effects of improving production efficiency, maintaining cell growth, and increasing permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0036] Bacteria: Klebsiella pneumoniae

[0037] Solid slant medium: beef extract 3g / L, MgSO 4 ·7H 2 O 0.2g / L, peptone 5g / L, NaCl 10g / L, agar 20g / L, glycerin 20g / L.

[0038] Seed medium: yeast extract 2g / L, MgSO 4 ·7H 2 O 0.2g / L, citric acid 0.42g / L, K 2 HPO 4 1.6g / L, K 2 HPO 4 3.4g / L, NH 4 Cl 3.0g / L, glycerol 30g / L, CaCl 2 0.5g / L.

[0039] Fermentation medium: glycerol 20-65g / L, K 2 HPO 4 ·3H 2 O 1.36g / L, NH 4 Cl 3.0g / L, yeast extract 2.0g / L, MgSO 4 ·7H 2 O 0.2g / L, CaCl 2 2.0g / L iron solution 1mL / L, inorganic ion solution 2mL / L, V B12 Solution 1mL / L, cobalt solution 1mL / L. Inorganic ions contain: CuCl 2 , H 3 BO 3 , MnCl 2 , Na 2 MoO 4 , NiCl 2 , ZnSO 4 , the content of trace elements is about 0.01-50mg / L.

[0040] Secondary seed preparation: take the fresh solid slant strain of Klebsiella pneumoniae, inoculate it in the seed medium, cultivate it on a shaker at 35°C at 150rpm for 24h, then inoculate it into the seed medium, and cultivate it at 35°...

Embodiment 1

[0044] 400ml of fermentation medium containing 45g / L industrial glycerin was placed in a 1L shake flask, and a volume of 40ml of secondary seeds was inserted, and the temperature was 37°C, and the shaker was cultivated at 180rpm. Add the concentration of 0%, 0.05%, 0.1%, 0.5%, 0.6%, 0.8%, 1% OP-10 respectively in the fermentation 8h, take samples at intervals, measure the cell concentration by spectrophotometer turbidimetry, the wavelength is 650nm , the cell concentration, that is, the amount of bacteria, is expressed as OD; the concentration of 1,3-propanediol is analyzed by gas chromatography. 24 hours to end fermentation.

[0045] Embodiment 1 has studied in fermenting glycerol to produce 1,3-propanediol technology, adds non-ionic surfactant OP-10, concentration is from 0~1.0% scope, different OP concentration is to Klebsiella pneumoniae growth and 1,3 - Effect of Propylene Glycol Yield. Figure 1 shows that at low concentrations, OP-10 mainly exhibits a promoting effect ...

Embodiment 2

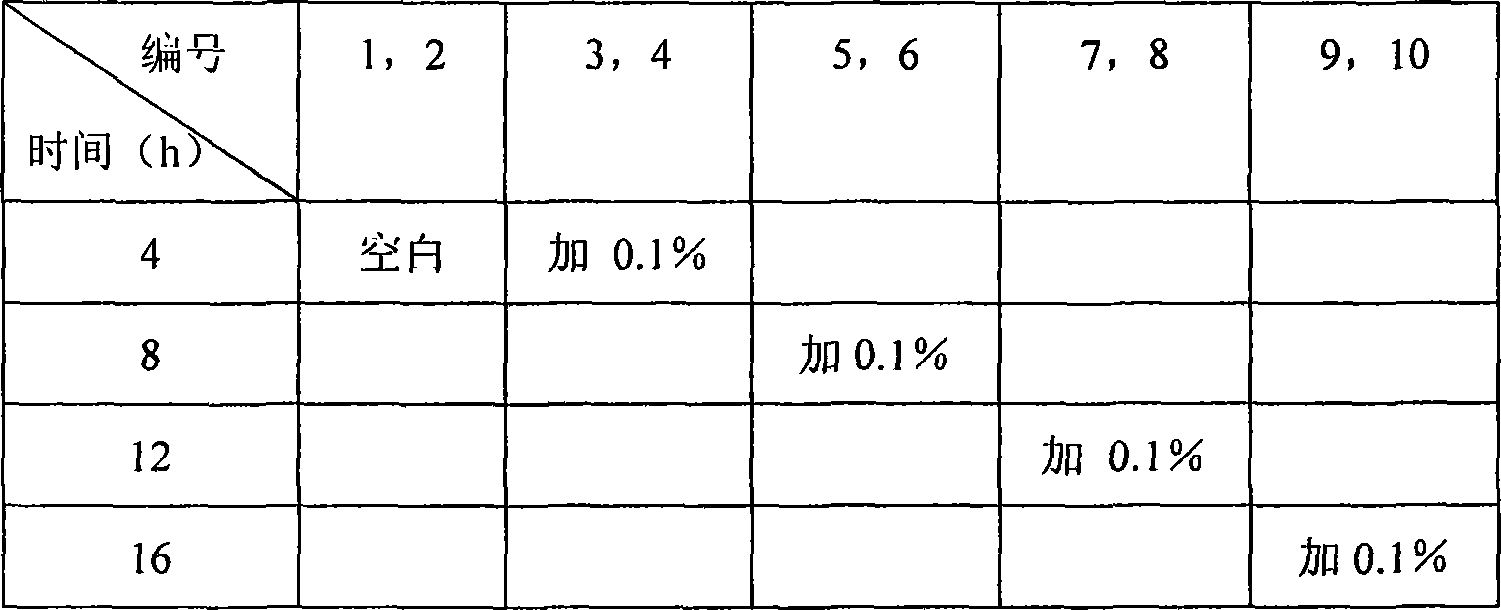

[0048] 400ml of fermentation medium containing 50g / L industrial glycerol was placed in a 1L shake flask, and a volume of 40ml of secondary seeds was inserted, and the temperature was 37°C, and the shaker was cultivated at 180rpm. 0.1% OP-10 was added at 4h, 8h, 12h and 16h of fermentation, and the fermentation was finished in 24 hours. The concentration of 1,3-propanediol was analyzed by gas chromatography.

[0049]

[0050] Table 1 Fermentation 4h, 8h, 12h, 16h respectively added concentration of 0.1% OP-10 shake flask number

[0051] As can be seen from Figure 3, the addition of OP at different stages of fermentation has a greater impact on the output of 1,3-propanediol, and the effect of adding OP in 8-16 hours is the best, and the maximum output of 1,3-propanediol has increased by 12%. .

[0052] Through the above experiments, it can be proved that in the process of producing 1,3-propanediol by fermentation of glycerol, the method of increasing the permeability of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com