Super-hydrophobic coating material, preparation method thereof and super-hydrophobic coating

A technology of super-hydrophobic coating and silicon-hydrogen bonding, which is applied in coatings and other directions, can solve the problems of cumbersome and complicated preparation methods of super-hydrophobic coatings, poor durability and practicability, and low mechanical strength, so as to achieve super-hydrophobic performance and durability. Good, high mechanical strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Unless otherwise specified, the steps of preparing superhydrophobic coating materials and coatings in the following examples are all carried out under normal pressure, and the temperature is normal temperature.

[0074] The superhydrophobic coating material that the present invention makes and the performance characterization of coating are as follows:

[0075] The viscosity of the polymer was measured at 25°C±1°C by a NDJ-1A rotational viscometer of China Shende Technology Development Co., Ltd.

[0076] The polymer molecular weight and its distribution were determined by a Waters Breeze 1515 high performance gel permeation chromatograph from Waters Corporation, USA.

[0077] The solid content of the emulsion was measured at 125°C with a Mettler-Toledo HB43-S halogen moisture analyzer.

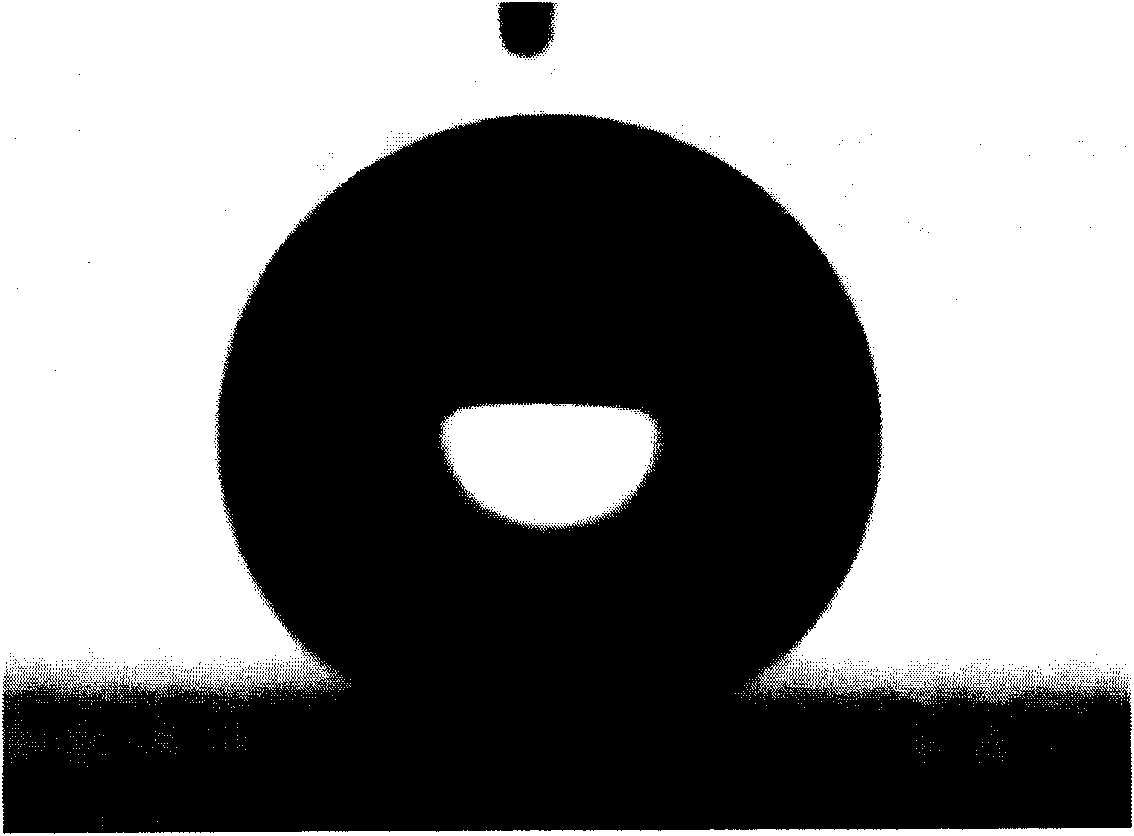

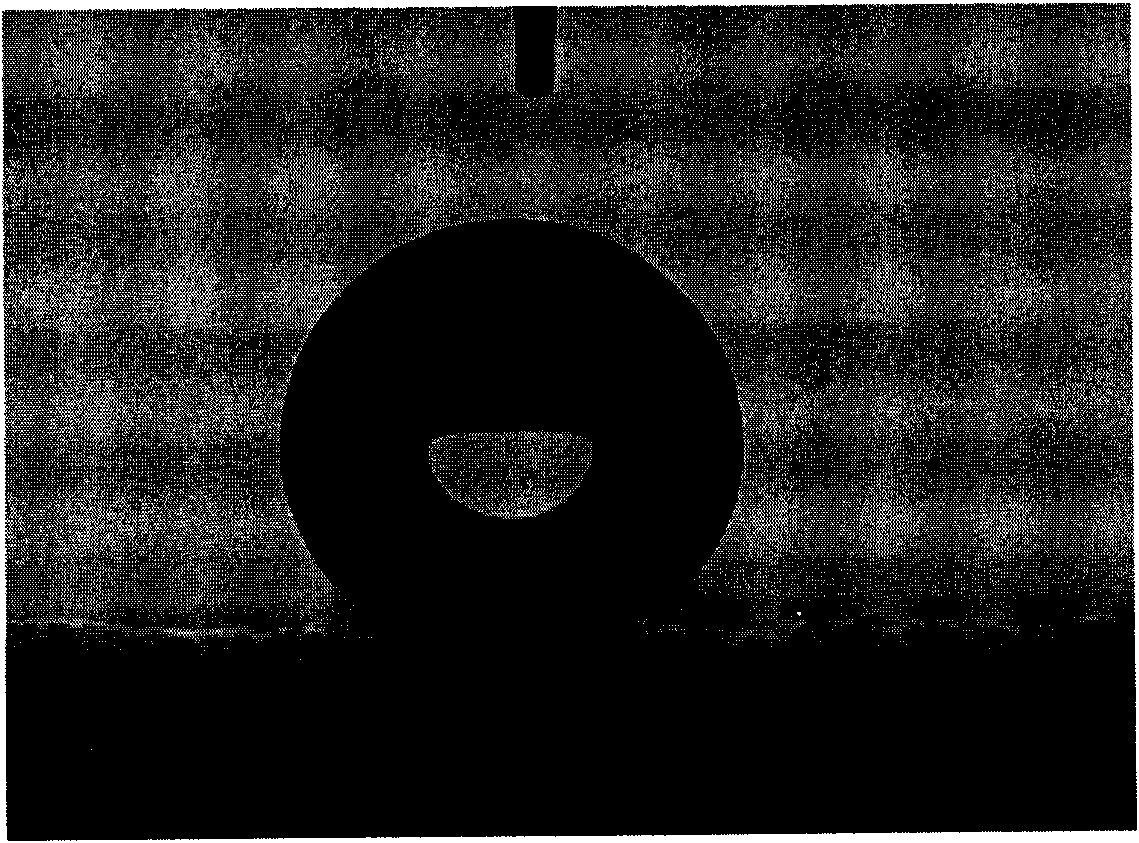

[0078] The contact angle and rolling angle of the superhydrophobic coating were measured by OCA-20 from Dataphysics, Germany.

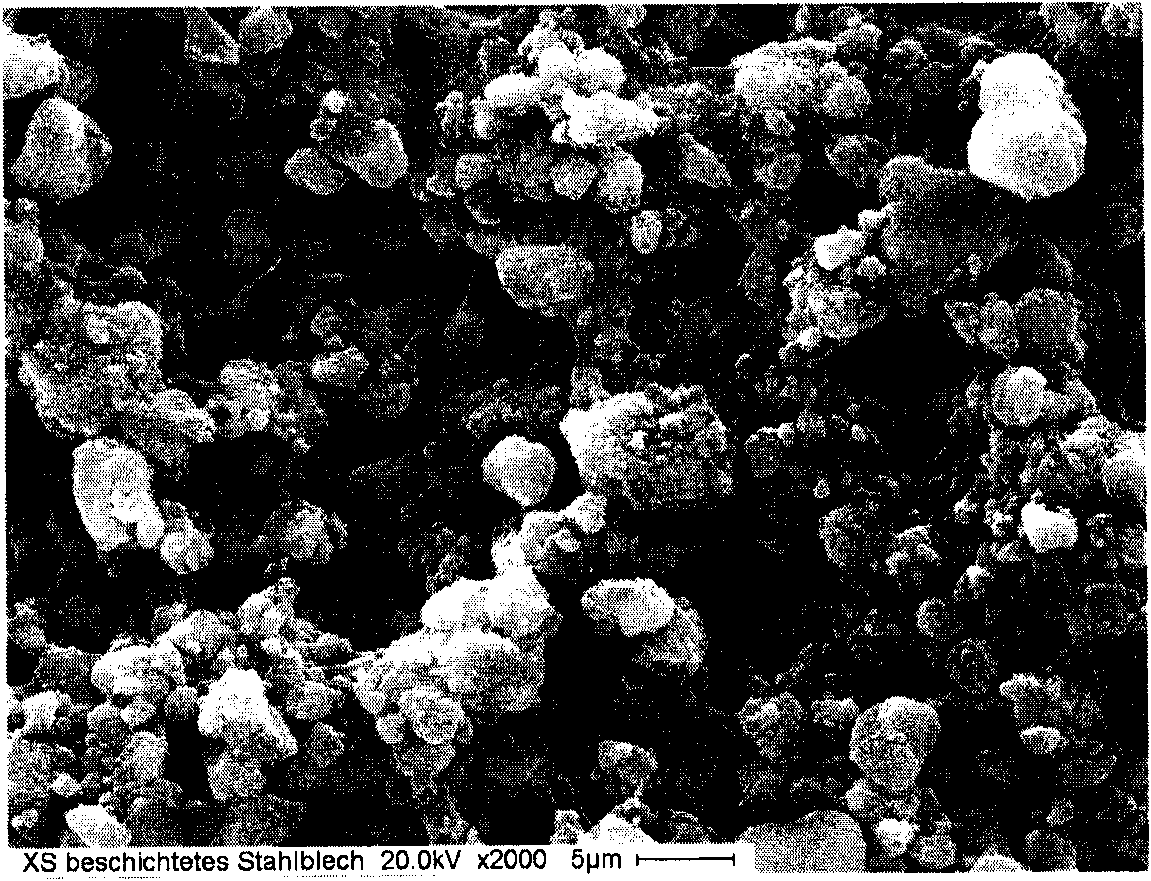

[0079] The surface morphology of the superhydrophobic c...

Embodiment 2

[0105] The preparation method of the super-hydrophobic coating material: at room temperature, add the components in Table 2 into a high-speed dispersion kettle, and stir at a speed of 1500 rpm for 20 minutes to make it evenly mixed. Then, at 1500 rpm, 92.36 g of deionized water was added dropwise at a constant speed within 30 minutes; after the dripping, continued stirring at 200 rpm for 30 minutes to obtain the final product.

[0106] The preparation method of the super-hydrophobic surface coating: the prepared super-hydrophobic coating material is sprayed on the metal substrate, and cured at 160° C. for 10 minutes to form a film to obtain the super-hydrophobic coating. The superhydrophobic coating has a water contact angle of 179.7° and a rolling angle of 3.44°.

[0107] Table 2

[0108]

Embodiment 3

[0110] The preparation method of the superhydrophobic coating material: at room temperature, add the components in Table 3 into a high-speed dispersion kettle, and stir at a speed of 1500rpm for 20 minutes to make it evenly mixed. Then, at 1500 rpm, add 46.6 g of deionized water dropwise at a constant speed within 30 minutes; after the dripping, continue stirring at 200 rpm for 30 minutes to obtain the final product.

[0111] The preparation method of the super-hydrophobic surface coating: the prepared super-hydrophobic coating material is sprayed on the metal substrate, and cured at 160° C. for 10 minutes to form a film to obtain the super-hydrophobic coating. The superhydrophobic coating has a water contact angle of 169.9° and a rolling angle of 9.4°.

[0112] The coating had a pencil hardness of 4H as measured by ASTM D3363-05.

[0113] table 3

[0114]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com