Application of reactive grease-based degradable surfactant

A surfactant and oil-based technology, which is applied in the application field of reactive oil-based degradable surfactants, can solve the problems of high cost and unsuitability for industrial application, and achieve the effects of low price, promotion of emulsion polymerization industry, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

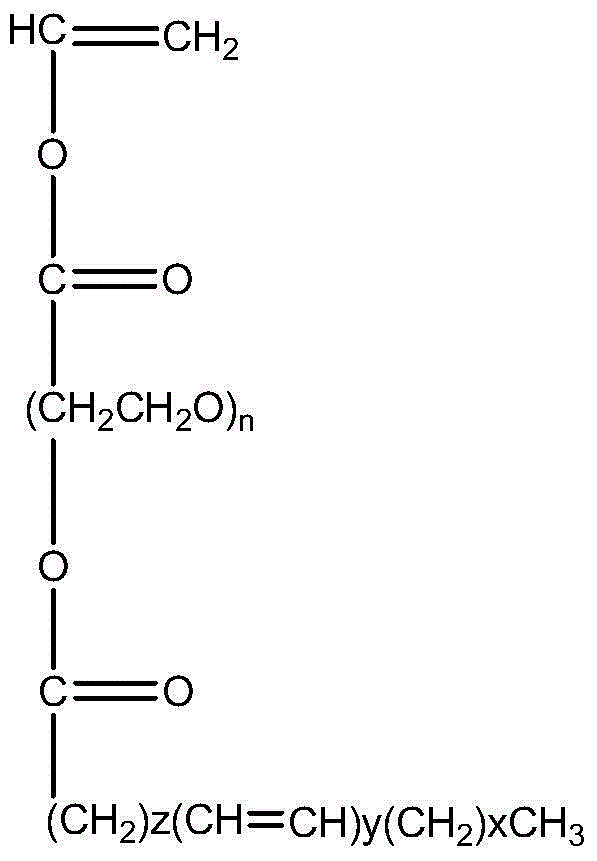

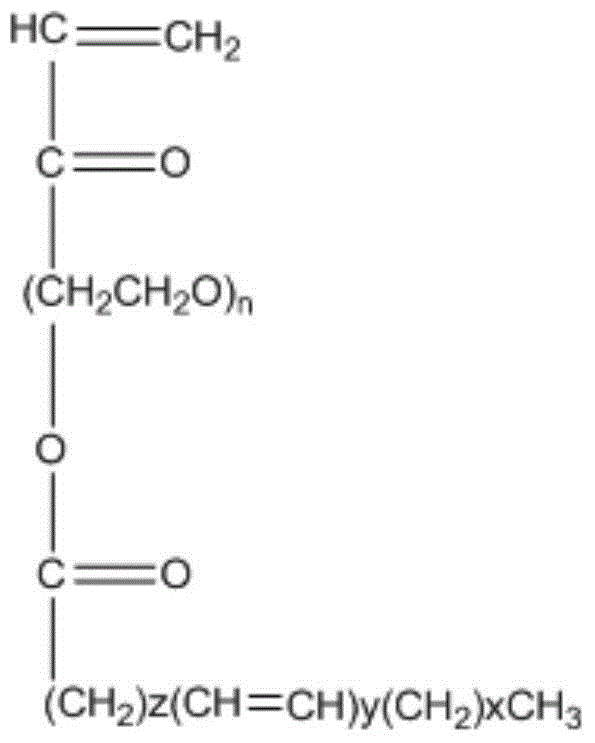

[0014] A kind of synthetic method of grease-based degradable surfactant provided by the invention comprises the following steps:

[0015] 1. Hydrolyzed oil: Mix 50 parts by mass of an acid catalyst with a mass concentration of 15-35% and 30-70 parts by mass of ethanol evenly, add it to the reactor, heat up to 50-100°C, and stir for 0.5-12 hours Add 20-60 parts of fats and oils to the reactor dropwise, keep warm for 0.5-24 hours, cool to room temperature, let stand to separate layers, take the upper layer and wash it with water for 5 times to obtain fatty acid;

[0016] 2. Esterification of fatty acid and polyether: dissolve 30-100 parts by mass of the fatty acid obtained in step 1 and the polyether in equal molar parts to the fatty acid in 100 parts by mass of toluene, add it to the reactor, and drop in 0.01-0.5 parts by mass of acid Catalyst, heat up to 50-150°C while stirring, stir and react for 0.5-24 hours, after the reaction is completed, vacuumize toluene at 50-100°C, an...

Embodiment 1

[0031] Preparation of oil-based degradable surfactant

[0032]1. Hydrolyzed oil: Mix 50 grams of sulfuric acid with a concentration of 15% and 30 grams of ethanol evenly, add it to the reactor, heat it up to 60°C, and add 20 grams of soybean oil dropwise to the reactor within 1 hour while stirring , cooling to room temperature after 2 hours of insulation reaction, after completion of the reaction, stand for stratification, take the upper layer and wash with water 5 times to obtain fatty acid;

[0033] 2. Esterification of fatty acid and polyether: Dissolve 30 g of fatty acid obtained in step 1 and polyether in equimolar fraction with fatty acid in 100 g of toluene, add it to the reactor, drop 0.01 g of concentrated sulfuric acid, and heat up to 100 g while stirring. 60 ℃, stirring and reacting for 1 hour, after the completion of the reaction, vacuuming at 60 ℃ to remove toluene, and then adding 30% NaHCO dropwise 3 Aqueous solution until no more bubbles are formed. Add 60 gr...

Embodiment 2

[0038] Preparation of oil-based degradable surfactants:

[0039] 1. Hydrolyzed grease: Mix 50 grams of hydrochloric acid with a mass concentration of 20% and 50 grams of ethanol uniformly, add it to the reactor, heat it up to 70°C, and add 50 parts of lard dropwise to the reactor within 4 hours while stirring , the reaction was incubated for 2 hours and then cooled to room temperature. After the reaction was completed, the layers were left to stand for stratification, and the upper layer was washed with water for 5 times to obtain fatty acids;

[0040] 2. Esterification of fatty acid and polyether: Dissolve 30 g of fatty acid obtained in step 1 and polyether in equimolar fraction of fatty acid in 100 parts of toluene, add it to the reactor, drop 0.1 g of concentrated sulfuric acid, and heat up to 100 g while stirring. 90°C, stirring and reacting for 2 hours. After the reaction is completed, toluene is removed by vacuuming at 60°C, and then NaHCO with a mass fraction of 30% is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com