Method for improving tensile strength of carbon fiber by utilizing graphene

A tensile strength and carbon fiber technology, which is applied in the field of graphene to improve the tensile strength of carbon fiber, can solve the problems of surface structural defects entering carbon fiber, affecting injection effect, etc., and achieves low cost, ideal effect and efficiency, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

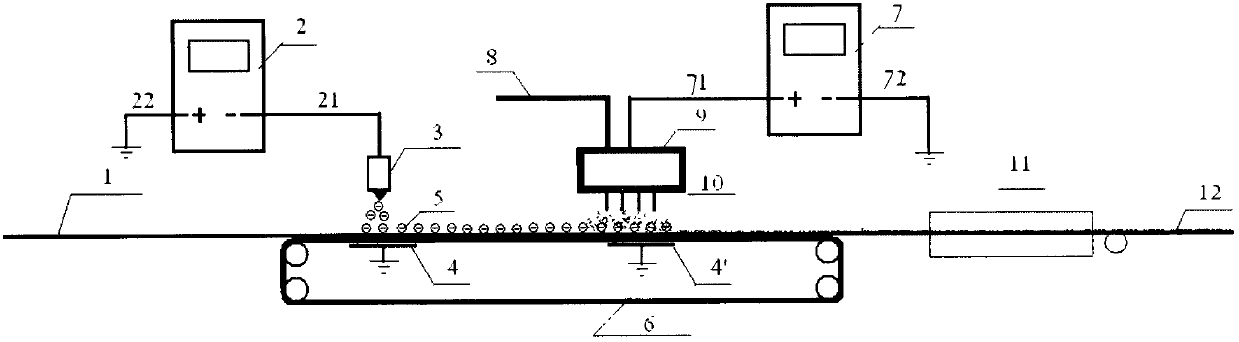

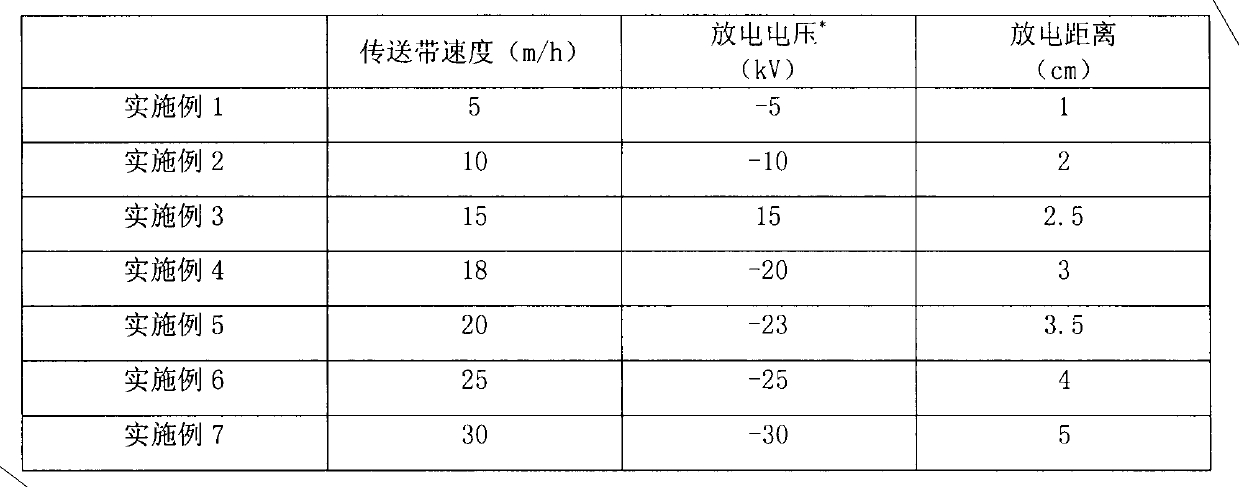

[0026] (1) Carbon fiber corona discharge treatment

[0027] The self-made unglued PAN-based carbon fiber was used for the test. The specification of the carbon fiber was: 3K, and the average diameter of the single fiber was 7.0 μm. Unfold the carbon fiber tow 1, spread it flat on the stainless steel conveyor belt 6 and send it to the high-voltage corona discharge area for corona discharge treatment. By controlling the appropriate speed of the conveyor belt 6, the corona discharge voltage of the high-voltage power supply 2, and the tip discharge The discharge distance between the device 3 and the ground electrode plate 4. The corona discharge process conditions of each embodiment are shown in Table 1.

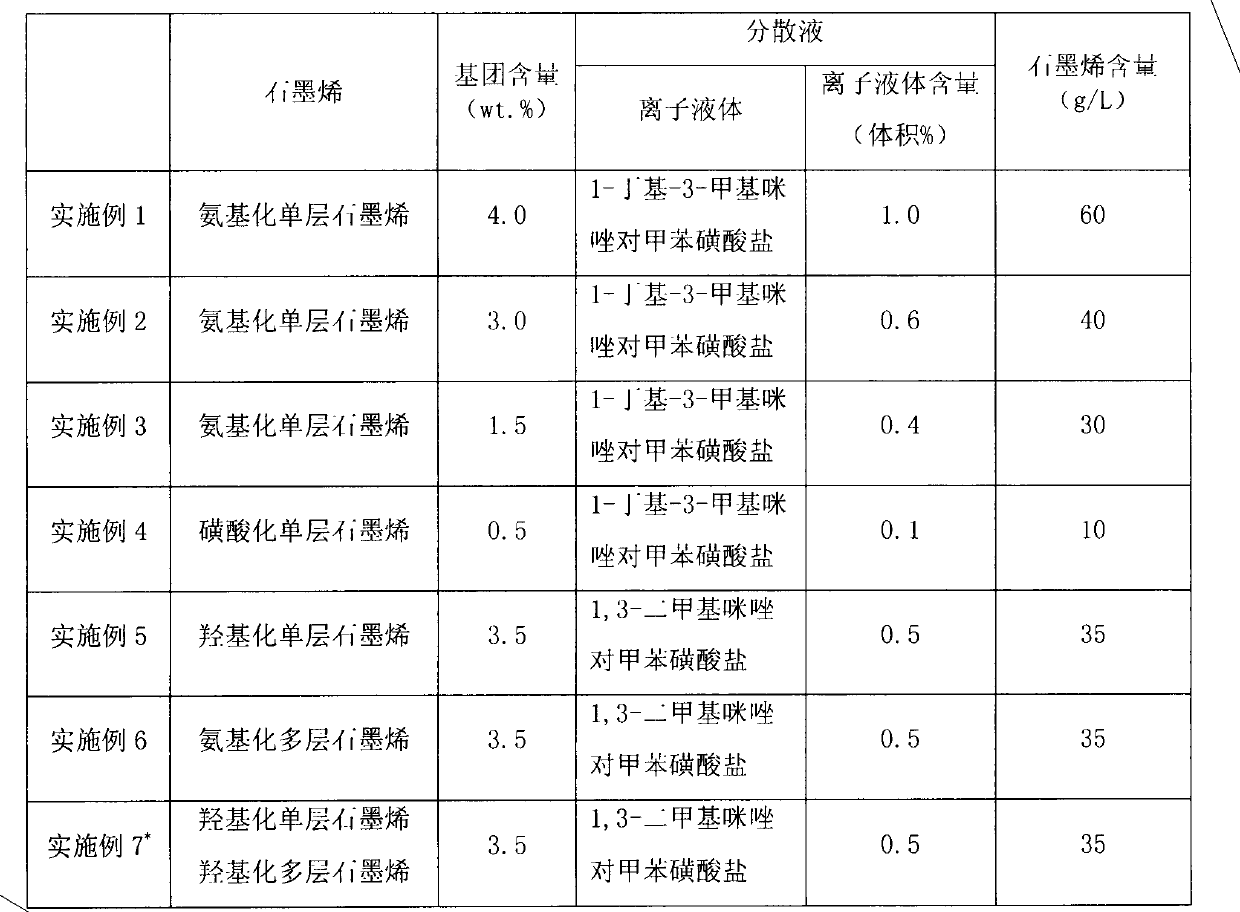

[0028] (2) Preparation of graphene suspension

[0029] Take the commercially available functionalized graphene and the dispersion prepared by distilled water and a small amount of ionic liquid and place it in the container according to the required ratio and mix it, then use u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com