Anode plate of lithium ion battery and its preparation method

A lithium-ion battery and anode technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of poor alloy-diaphragm interface, uneven stress distribution, uneven coating of anode active materials, etc. Achieving good buffering effect and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

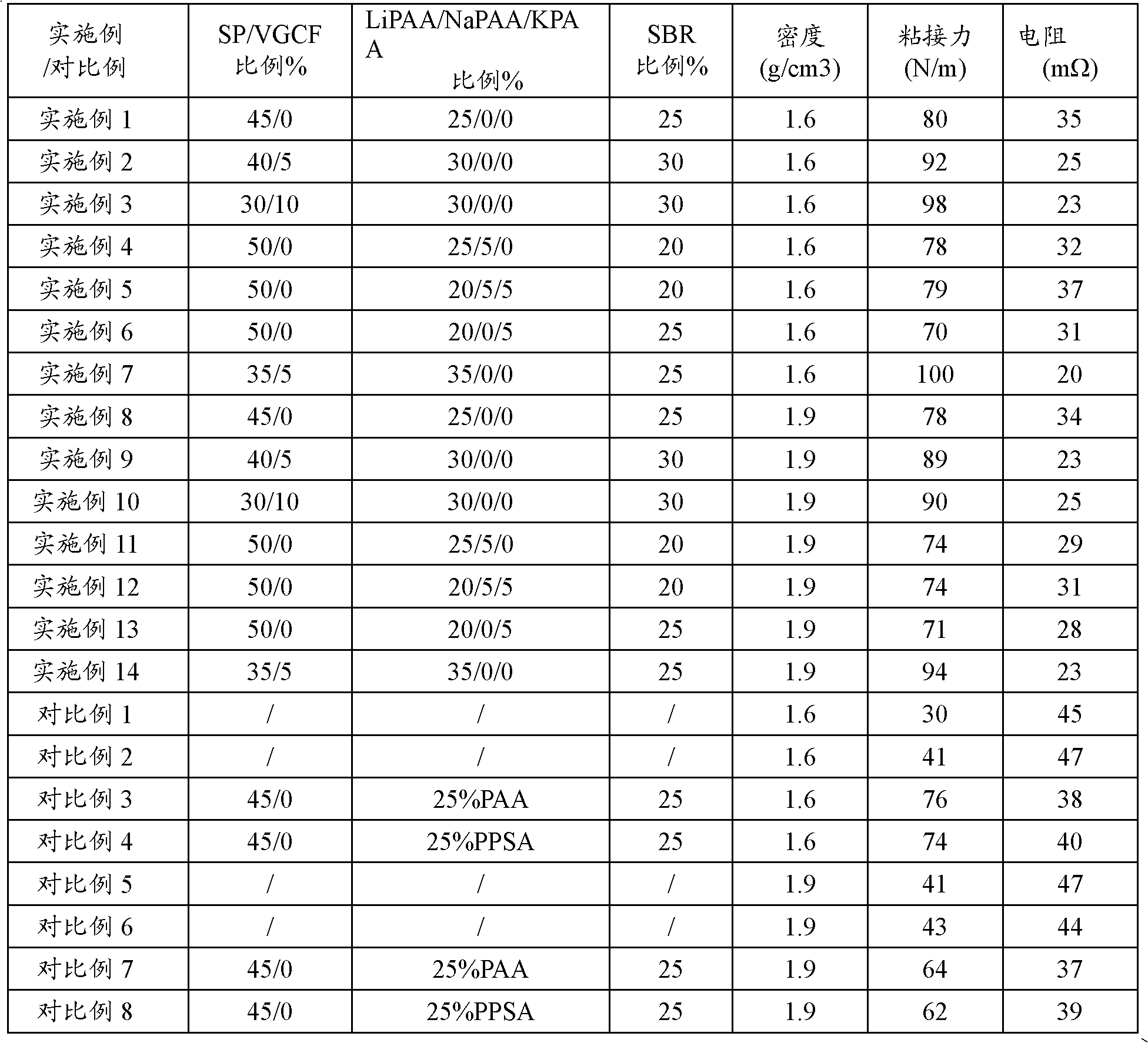

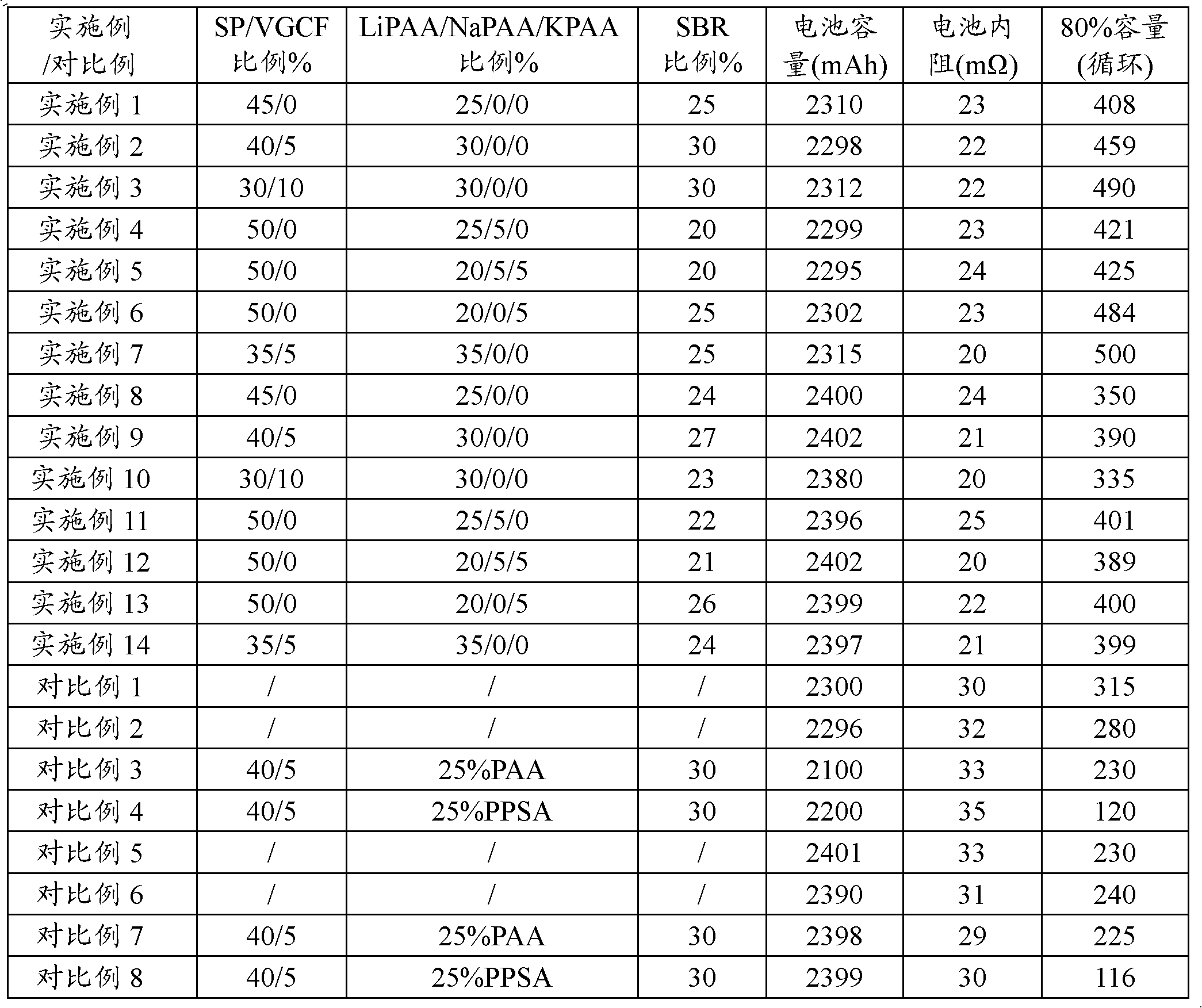

Embodiment 1

[0026] Preparation of the cathode: using lithium cobalt oxide (LiCoO 2 ) as the cathode active material, prepare the slurry containing lithium cobaltate cathode active material: by weight percentage, the solid content of slurry comprises 90% lithium cobaltate as the cathode active material, 5% polyvinylidene fluoride (PVDF) As an adhesive, 5% conductive carbon black (SP) is used as an electronic conductivity aid, and N-methylpyrrolidone (NMP) is used as a solvent, wherein the weight of the solvent accounts for 55% of the total slurry weight; high-speed stirring is uniformly dispersed After that, it is evenly coated on both sides of the aluminum foil, blown and dried, and then cold-pressed with a roller press, and the cathode electrode sheet is obtained after cutting and other processes.

[0027]Anode current collector treatment: copper foil is used as the anode current collector. In weight percentage, the treatment layer contains 45% conductive carbon black (SP), 30% alkali me...

Embodiment 2

[0031] In terms of dry weight percentage, the treatment layer slurry contains 45% conductive carbon black (40% SP+5% VGCF), 25% lithium polyacrylate (Li-PAA) and 30% styrene-butadiene latex (SBR), The solvent is deionized water, which accounts for 80% of the total weight of the slurry, and the others are the same as in Example 1.

Embodiment 3

[0033] In terms of dry weight percentage, the treatment layer slurry contains 40% conductive carbon black (30% SP+10% VGCF), 30% lithium polyacrylate (Li-PAA) and 30% styrene-butadiene latex (SBR), The solvent is deionized water, which accounts for 80% of the total weight of the slurry, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com