A kind of self-healing anti-cracking concrete and preparation method thereof

A concrete and self-healing technology, applied in the field of concrete, can solve the problems of increasing cracks and poor repairing effect, and achieve the effect of preventing further expansion of cracks and not easy to stick to each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

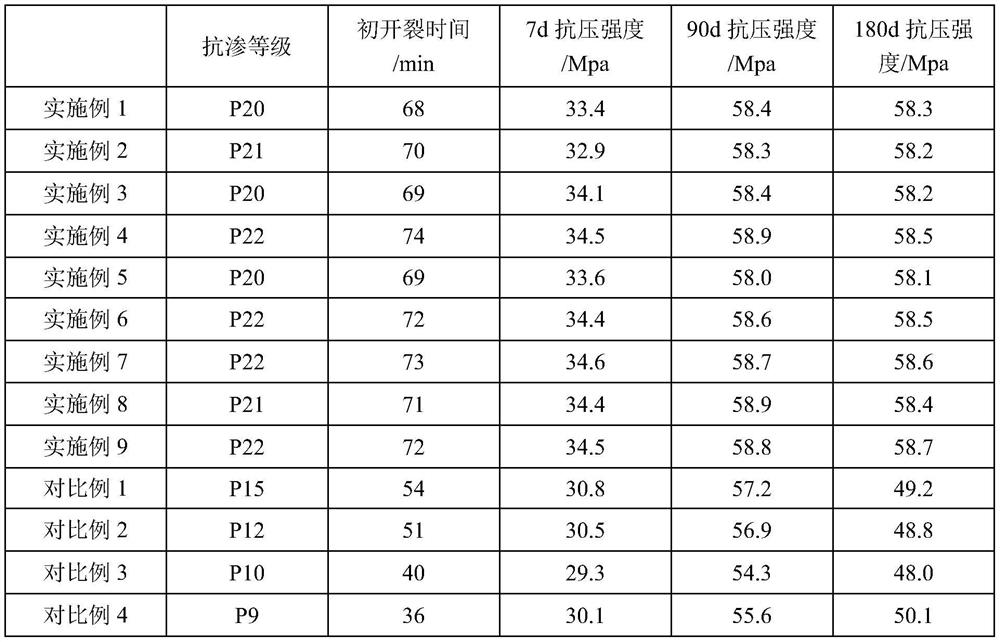

Examples

preparation example 1

[0043] The glass fiber tube into which the adhesive is injected, the preparation steps are as follows:

[0044] 1) pulverizing and heating the waste glass to obtain glass liquid;

[0045] 2) Inject the glass liquid into the mold to obtain a glass fiber tube with one end sealed and one end open. The outer diameter of the glass fiber tube is 2mm, the length is 15cm, and the wall thickness is 0.3mm, and a liquid adhesive is injected into the glass fiber tube, The injection amount of the adhesive is 80% of the volume of the glass fiber tube, and then the obtained glass fiber tube is sealed by hot pressing to obtain the glass fiber tube injected with the adhesive.

preparation example 2

[0047] The glass fiber tube into which the adhesive is injected, the preparation steps are as follows:

[0048] 1) pulverizing and heating the waste glass to obtain glass liquid;

[0049] 2) Inject the glass liquid into the mold to obtain a glass fiber tube with one end sealed and one end open. The outer diameter of the glass fiber tube is 4mm, the length is 10cm, and the wall thickness is 0.5mm, and a liquid adhesive is injected into the glass fiber tube, The injection amount of the adhesive is 70% of the volume of the glass fiber tube, and then the obtained glass fiber tube is sealed by hot pressing to obtain the glass fiber tube injected with the adhesive.

preparation example 3

[0051] The glass fiber tube into which the adhesive is injected, the preparation steps are as follows:

[0052] 1) pulverizing and heating the waste glass to obtain glass liquid;

[0053] 2) Inject the glass liquid into the mold to obtain a glass fiber tube with one end sealed and one end open. The outer diameter of the glass fiber tube is 3mm, the length is 13cm, and the wall thickness is 0.4mm, and a liquid adhesive is injected into the glass fiber tube, The injection amount of the adhesive is 75% of the volume of the glass fiber tube, and then the obtained glass fiber tube is end-sealed by hot pressing to obtain the glass fiber tube injected with the adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com