Electromagnetic relay capable of resisting short-circuit current

An electromagnetic relay and anti-short-circuit technology, which is applied in the direction of electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of contact bonding failure, low short-circuit resistance capability, increased cost and structural assembly difficulty, etc., to reduce contact Point bounce, improve the ability to resist short-circuit current, and improve the effect of contact stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

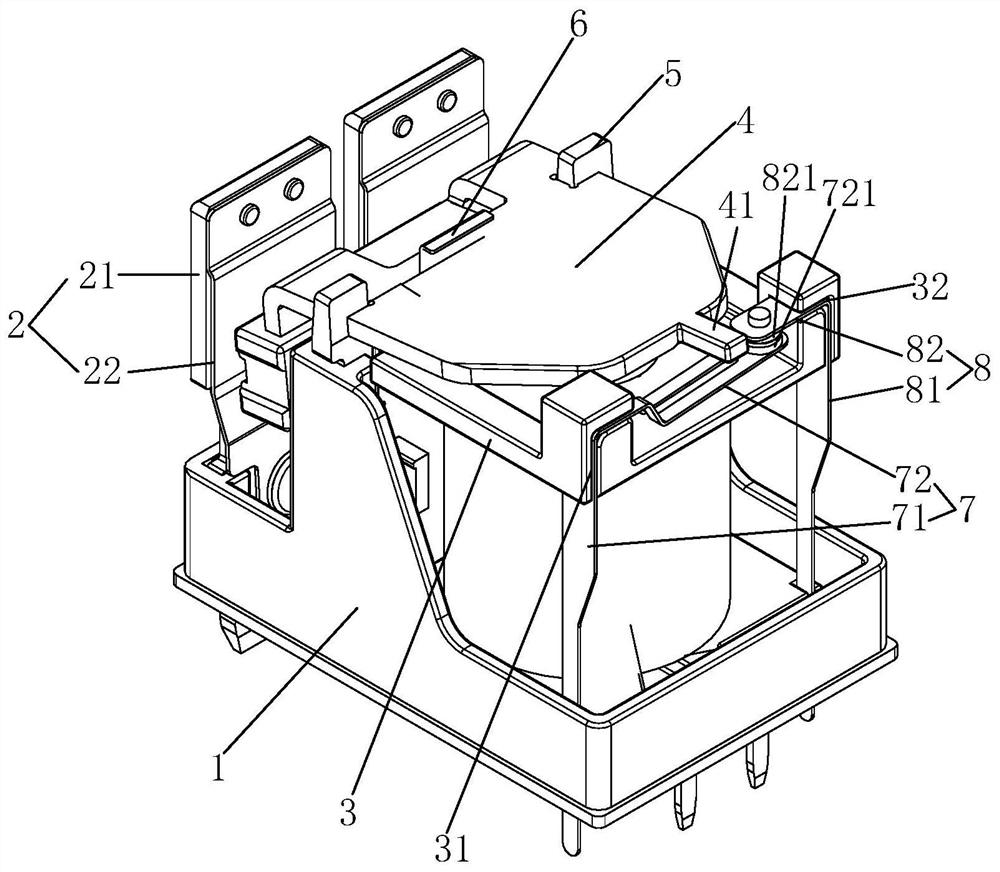

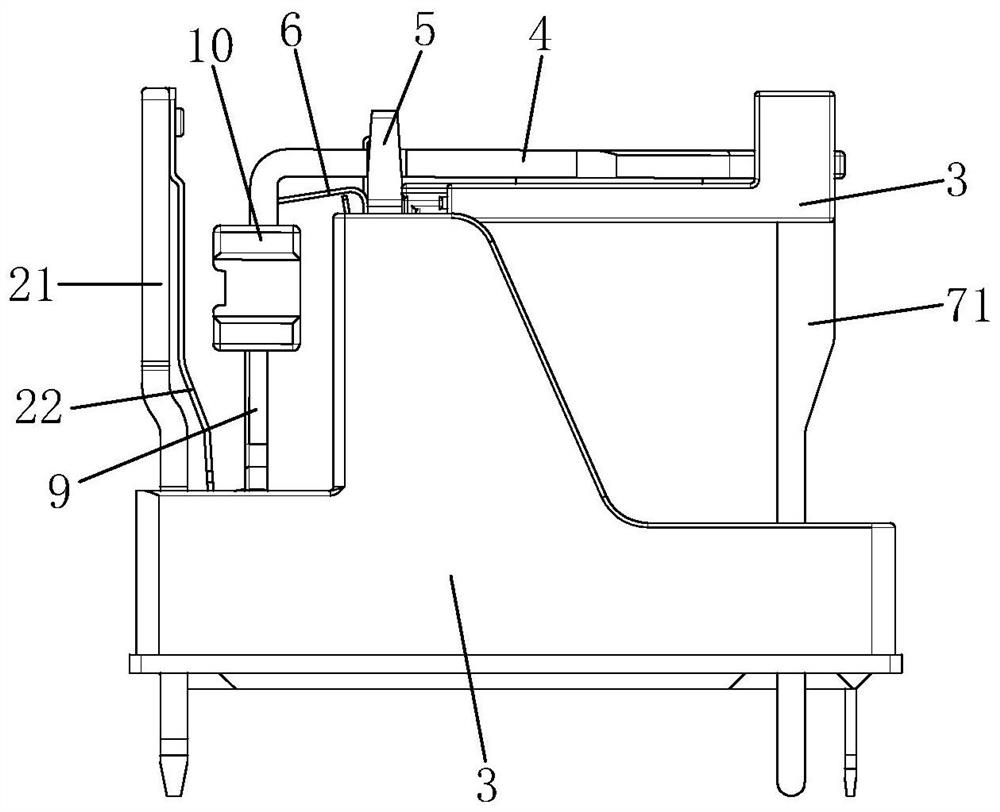

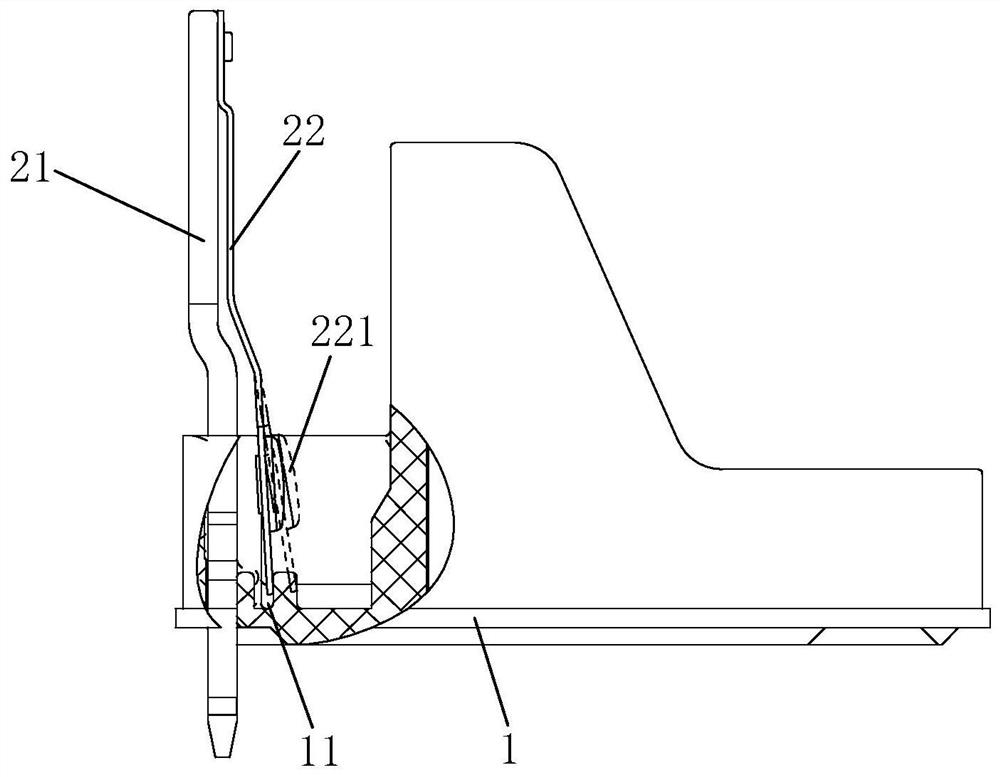

[0031] See Figure 1-Figure 5 As shown, an electromagnetic relay against short-circuit current of the present invention includes a base 1, a magnetic circuit part, a static spring part 2 and a moving spring part, and the static spring part 2 includes a static spring lead-out piece 21 and an elastic static spring piece 22 The static spring lead-out piece 21 is arranged on the base 1, and the static contact 221 is set on the static spring piece 22. The static spring piece 22 is electrically connected with the static spring lead-out piece 21, and the direction of the static spring piece 22 faces the moving spring part in the energized state. The electromotive force can resist the electromotive repulsion force received by the static contact 221. The electromotive force is greater than the electromotive repulsion force, and / or, when the static contact 221 is in contact with the movable contact 91 of the movable spring part, the static spring piece 22 generates an elastic preload di...

Embodiment 2

[0047] See Figure 6 As shown, the electromagnetic relay against short-circuit current of the present invention differs from the first embodiment above in that: the coil former 3 and / or the base 1 of the present invention do not position the auxiliary moving reed and the auxiliary static reed, The armature 4 is also not provided with the drive part.

[0048] In this embodiment, the rest of the structure of the present invention is the same as that of the first embodiment above, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com