Control method and device of A2/O oxidation trench technology synchronous nitration and denitrification

A technology of simultaneous nitrification and control device, applied in the field of biological denitrification, can solve the problems of low environment and difficult to control, high energy consumption, low total nitrogen removal efficiency, etc., to solve optimization and control, save carbon source, and solve sewage denitrification The effect of unstable efficiency and low compliance rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

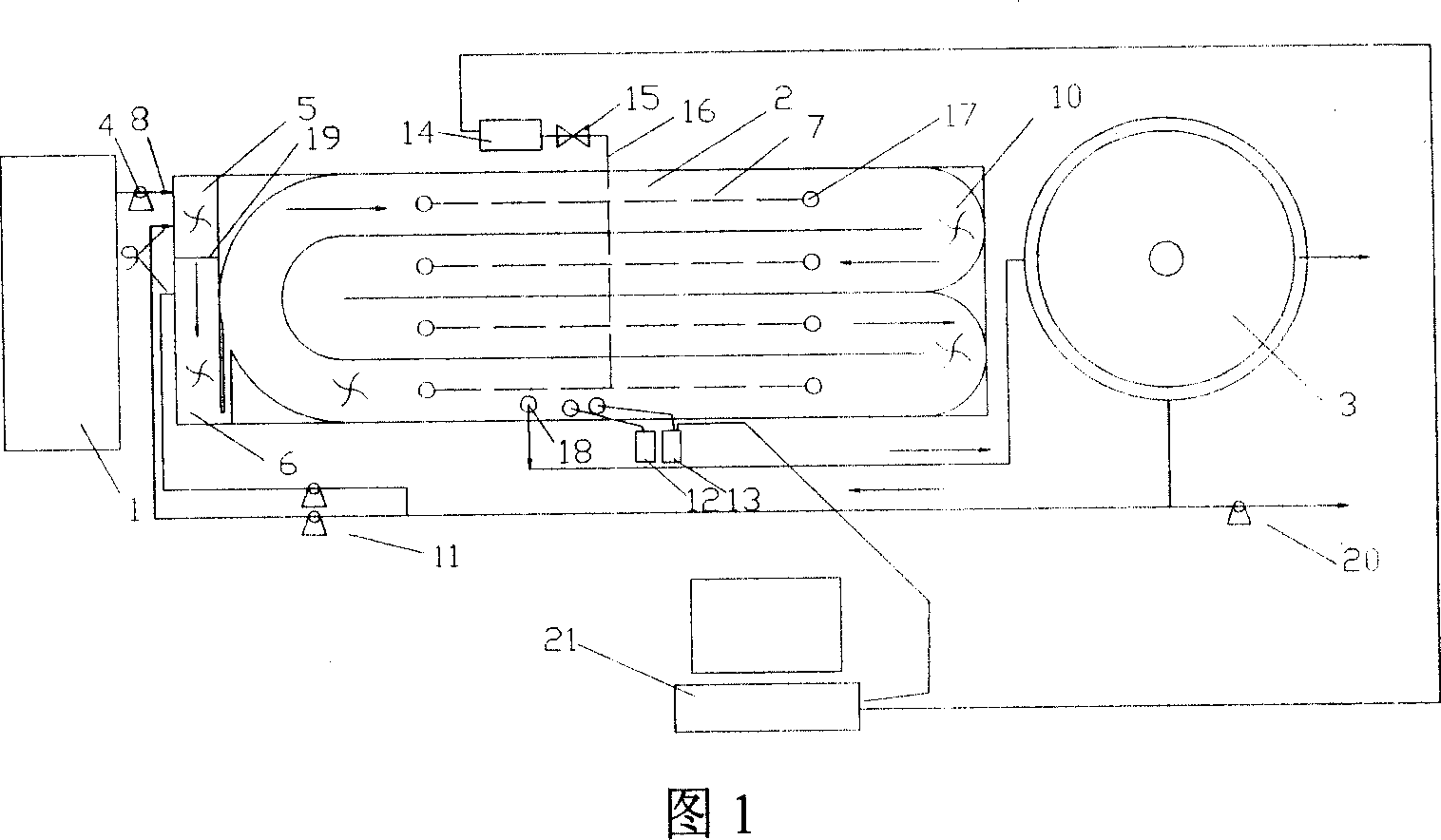

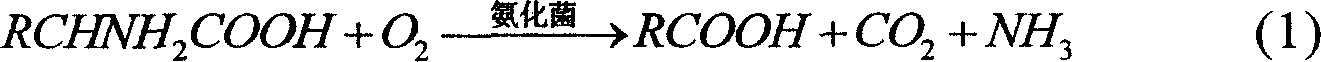

[0074] Taking the effluent from the aeration grit chamber of a sewage treatment plant in Beijing as the raw water, the influent COD, ammonia nitrogen, total nitrogen and total phosphorus values (COD=251.2~489.4mg / L, NH 4 + =35.5~51.2mg / L, TN=49.4~65.4mg / L, TP=5.4~8.7mg / L). The hydraulic retention time (HRT) of the anoxic zone, the anaerobic zone and the oxidation ditch are 0.5h, 1.5h and 18h respectively, the reflux ratio is 100%, the average flow velocity in the oxidation ditch aeration tank is about 1cm / s, and it takes 5 to 7 minutes. Oxidation-reduction potential (ORP) was used as the control parameter of simultaneous nitrification and denitrification (SND) biological denitrification (SND) in the oxidation ditch process.

[0075] COD, BOD in the test stage 5 , NH 4 +, The average influent concentration of TN is 337.8mg / L, 177.4mg / L, 52.7mg / L and 38.5mg / L, and the average effluent concentration is 45.3mg / L, 12.5mg / L, 13.2mg / L, 4.2mg / L L, the average removal rates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com