Automated production device for styrene-acrylic emulsion mixing and automated control method of automated production device

A technology for styrene-acrylic emulsion and production equipment, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as loss of reaction materials, production accident hazards, etc., to ensure product quality, broad application prospects, and ensure safety. The effect of production and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

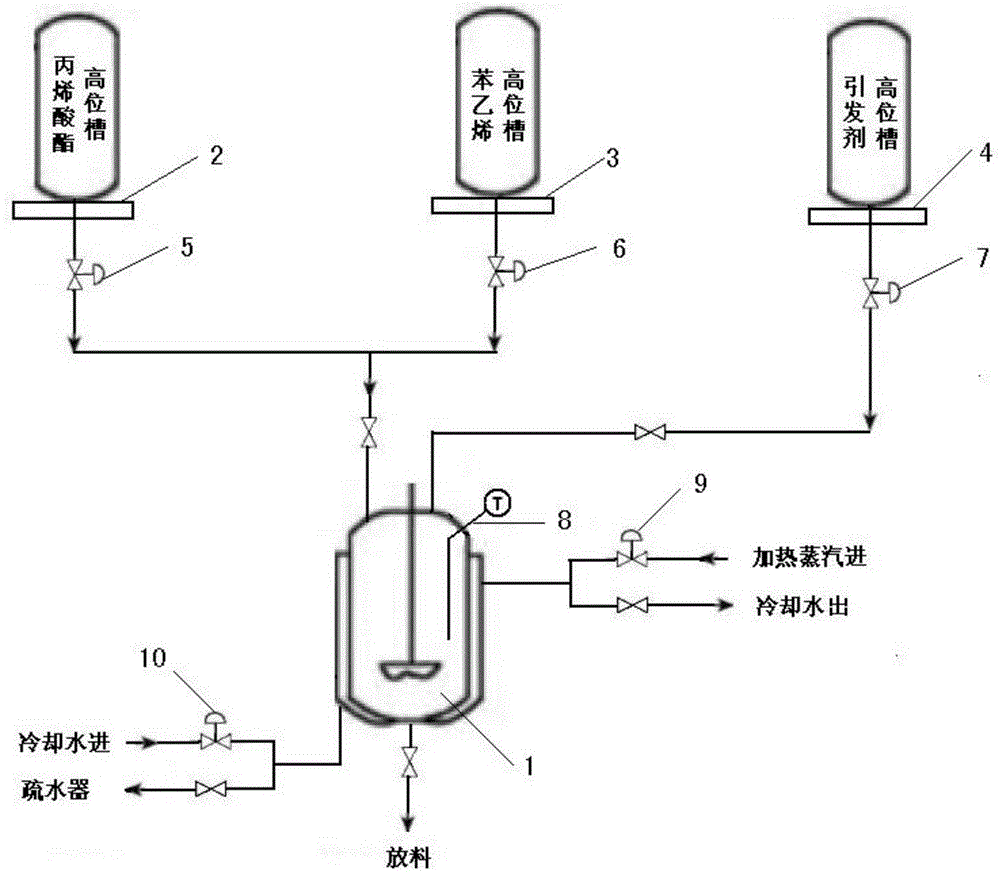

[0024] Such as figure 1 Shown, the present invention is a kind of automatic production device that is used for styrene-acrylic emulsion polymerization, and it comprises PLC control system (not drawing on the figure), polymerization reactor 1 and the acrylate elevated tank that is connected with polymerization reactor respectively by pipeline, Styrene header tank and initiator header tank; the jacket of the polymerization reactor is equipped with heating steam pipes or cooling water pipes; the bottom of the acrylate header tank, styrene header tank and initiator header tank are equipped with weight sensors 2, 3, 4, The weight sensors are all connected to the input ports of the PLC control system; the pipelines connecting the acrylate header tank, the styrene header tank and the initiator header tank to the polymerization reactor are respectively provided with control valves 5, 6, 7, these control valves All are connected with the output ports of the PLC control system; the poly...

Embodiment 2

[0026] The automatic production method of the automatic production device that is used for styrene-acrylic emulsion polymerization described in embodiment 1, concrete operating steps are as follows:

[0027] (1), add initiator and water in initiator header tank and make initiator solution for subsequent use;

[0028] (2), add the metered styrene material in the styrene head tank for standby;

[0029] (3) Inhale the metered required acrylate in the acrylic high-level tank, and set it aside; (note that the raw materials and feeding amounts of different brands of adhesives are different, and must be operated according to the product formula)

[0030] (4) Add a certain amount of deionized water into a clean glass-lined polymerization reactor, start stirring, add emulsifier, and add acrylate amine; turn on the automatic control device; add 1 / 3 of the amount automatically from the two high-level tanks of raw materials acrylate monomer (weight) and 1 / 3 amount of styrene (weight), st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com