Non-iron finishing method for piece-dyed pure cotton fabric

A non-iron finishing and fabric technology, applied in the field of non-ironing finishing of pure cotton piece dyed fabrics, can solve the problems of low formaldehyde and environmental protection, achieve soft hand feeling, reduce washing, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

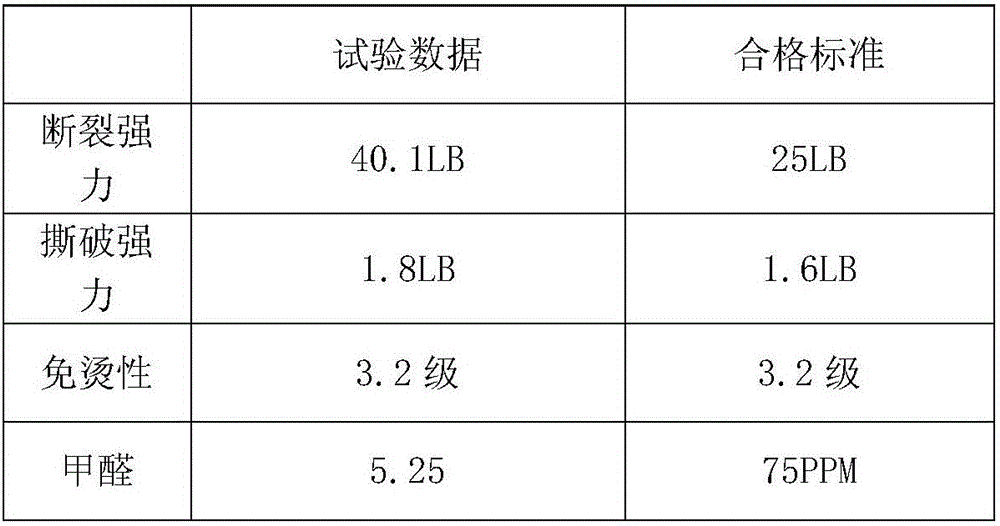

Embodiment 1

[0014] Embodiment 1: The fabric specification is: plain weave fabric of CM50*CM80 / 2T*160*70*60 / 61, and the technical process is as follows:

[0015] Cloth turning: singeing, deboiling, bleaching, mercerizing, liquid ammonia, non-ironing, baking, washing, tentering, shrinking and packing inspection

[0016] Cloth turning process: the front and back are consistent, and the seam is straight and firm;

[0017] Singeing process: Singeing is clean;

[0018] Desizing and scouring process: desizing is clean, the desizing rate reaches over 98%, and the hair effect after scouring reaches 5cm / 5min to ensure the non-ironing effect and hand feeling;

[0019] Bleaching process: the whiteness of the bleached fabric reaches 87 in CIE resin under D65 light source;

[0020] Mercerizing process: mercerizing is sufficient, and the pH value of the cloth surface is 7-9.

[0021] Liquid ammonia finishing process: adopt conventional liquid ammonia finishing, and the pH value of the fabric after li...

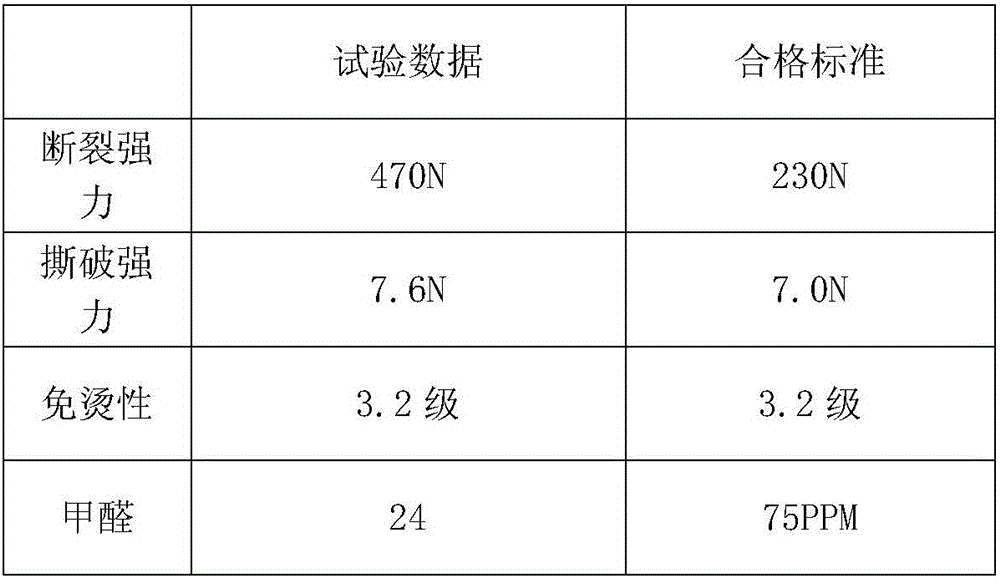

Embodiment 2

[0029] Embodiment 2: the fabric specification is: the plain weave fabric of CPT36*CPT36*112*80 plain weave, and the technical process is as follows:

[0030] Cloth turning: singeing, deboiling, bleaching, mercerizing, liquid ammonia, non-ironing, baking, washing, tentering, shrinking and packing inspection

[0031] Cloth turning process: the front and back are consistent, and the seam is straight and firm;

[0032] Singeing process: Singeing is clean;

[0033] Desizing and scouring process: desizing is clean, the desizing rate reaches over 98%, and the hair effect after scouring reaches 5cm / 5min to ensure the non-ironing effect and hand feeling;

[0034] Bleaching process: the whiteness of the bleached fabric reaches 87 in CIE resin under D65 light source;

[0035] Mercerizing process: mercerizing is sufficient, and the pH value of the cloth surface is 7-9.

[0036] Liquid ammonia finishing process: adopt conventional liquid ammonia finishing, and the pH value of the fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com