Method for preparing mesocarbon microbeads by copolycondensation

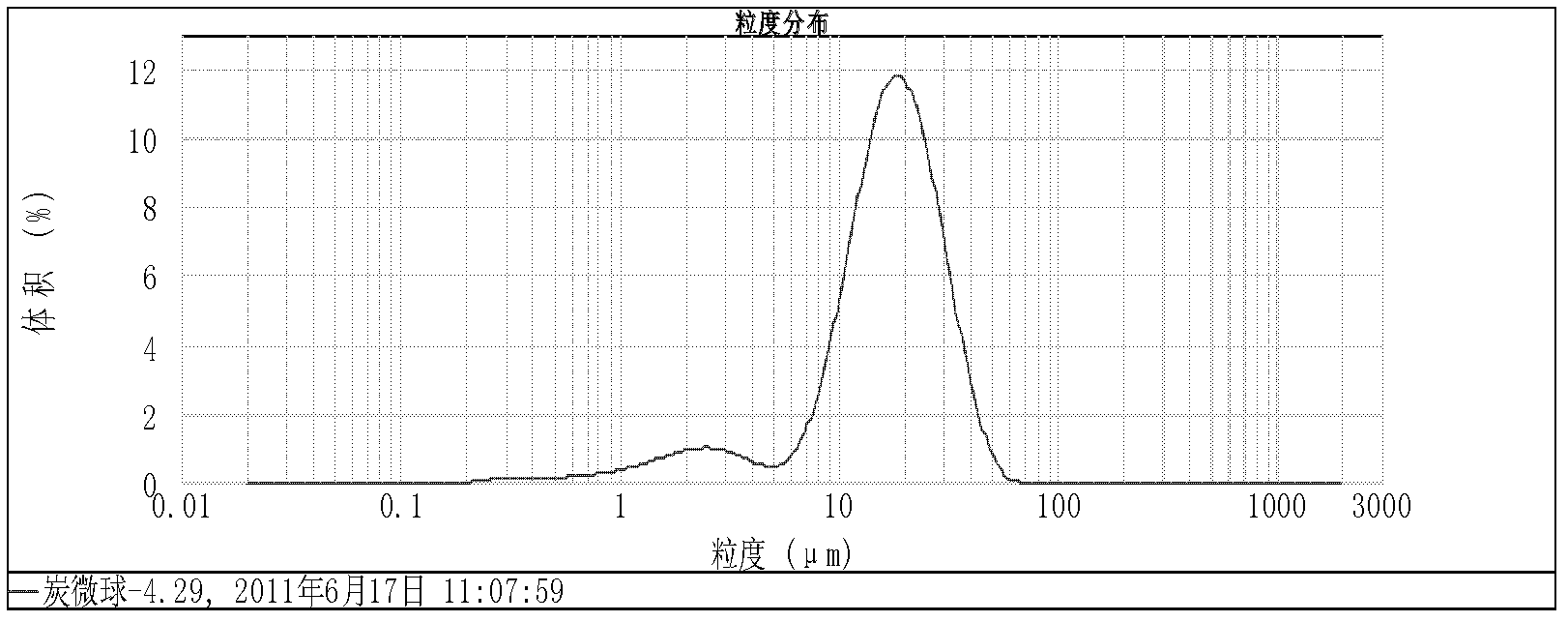

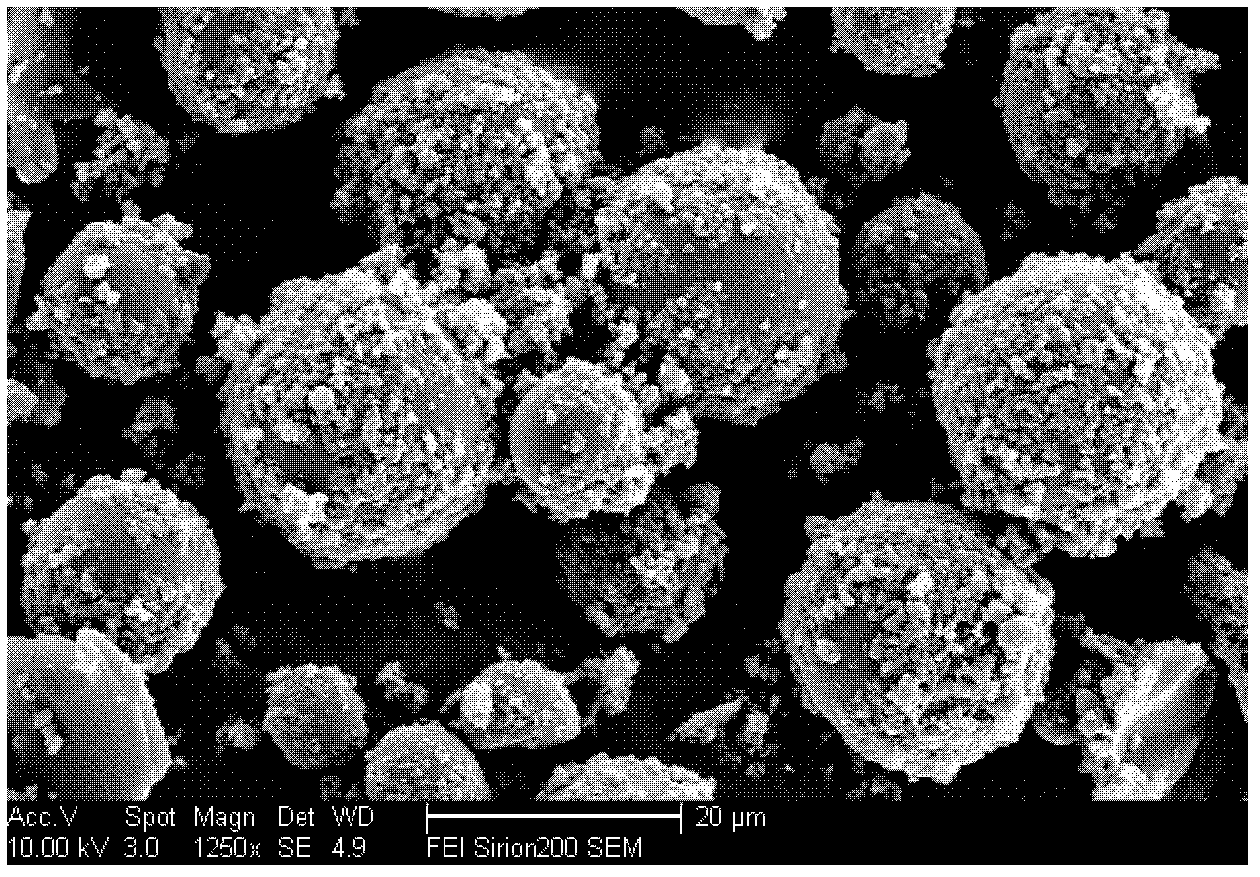

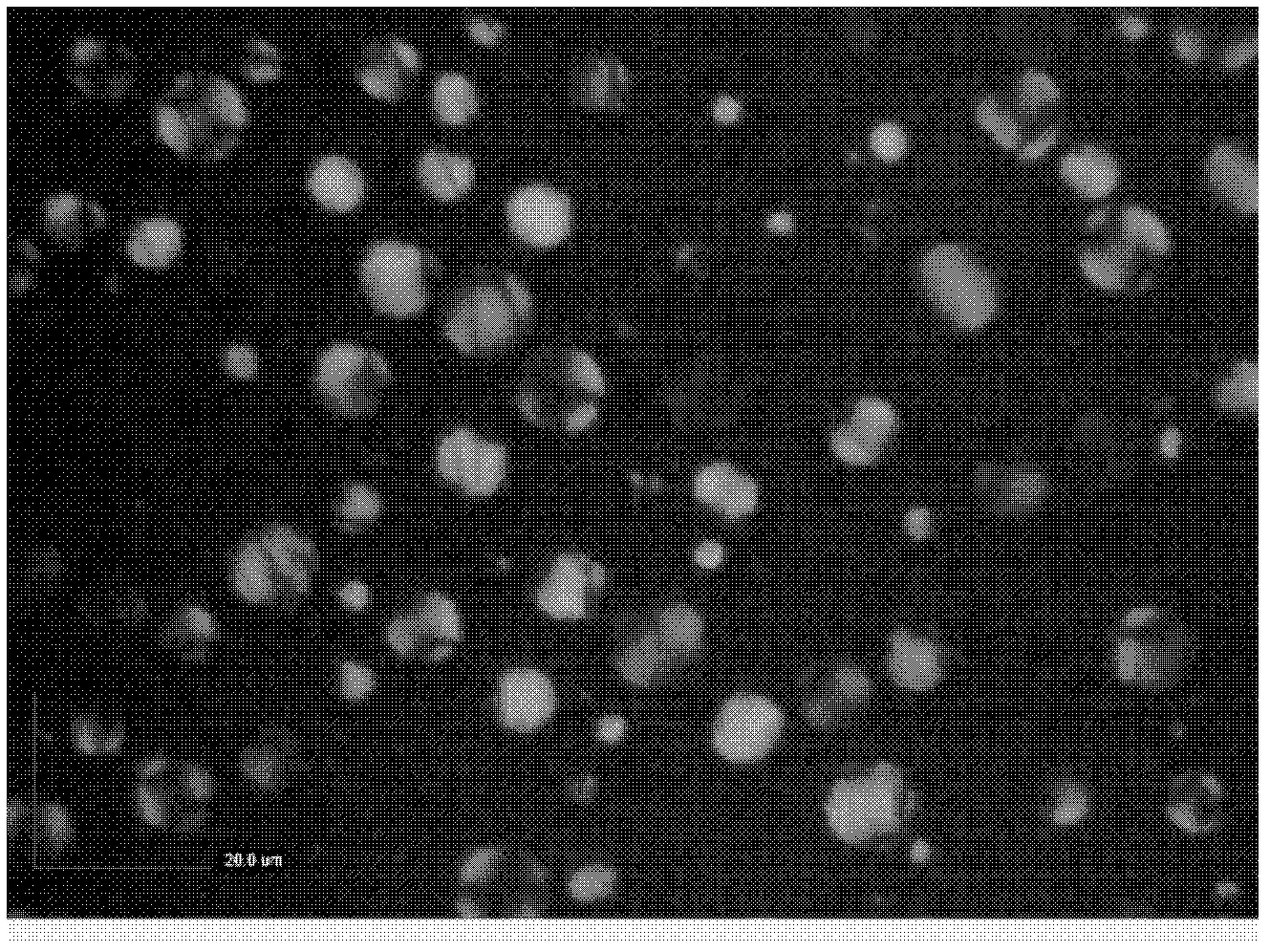

A technology of mesophase carbon microspheres and copolycondensation, which is applied in the preparation/purification of carbon, can solve problems such as difficulty in uniform dispersion, and achieve the effect of narrow particle size distribution and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Blend 200 g of medium-temperature coal tar pitch with a QI content of 3% in quinoline insolubles and 300 g of coal liquefaction residue-based pitch without QI and add it to a 1L reactor, then add 1% (5 g) of nano-coke powder accounting for the total weight of the blend , stirred at 300°C for 20min at high speed under the protection of nitrogen, then raised the temperature to 420°C, and heat-treated for 8.5h under the pressure of 1.5MPa and stirring at 300 rpm to obtain the mother liquor pitch containing MCMB. The washing oil is used for high-temperature centrifugation, and then the tetrahydrofuran solvent is used for several times of centrifugal washing, followed by filtering and drying to obtain the MCMB product. The yield is 28% based on raw pitch.

Embodiment 2

[0027] Blend 300 g of medium-temperature coal tar pitch with a quinoline-insoluble QI content of 3% and 200 g of coal liquefaction residue-based pitch without QI into a 1L reactor, stir at 300°C for 20 minutes under nitrogen protection, and then heat up to 420°C. Under the pressure of 1 MPa and stirring at 300 rpm, heat treatment for 8 hours to obtain the mother liquor pitch containing MCMB. The medium oil is used for high-temperature centrifugation, and then tetrahydrofuran is used for several times of centrifugal washing, followed by filtering and drying to obtain the MCMB product. The yield is 20% based on raw pitch.

Embodiment 3

[0029] Blend 400g of medium-temperature coal tar pitch with 3% quinoline-insoluble QI content and 100g of coal liquefaction residue-based pitch without QI into a 1L reactor, add 0.5% carbon black, and stir at 300°C for 20min under nitrogen protection , and then raised the temperature to 420°C, under the pressure of 0.5MPa and stirring at 300 rpm, heat treatment for 8.5h to obtain the mother liquor pitch containing MCMB. The washing oil is used for high-temperature centrifugation, followed by several times of centrifugal washing with pyridine, followed by filtration and drying to obtain the MCMB product. The yield is 30% based on raw pitch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com