Technology of preparing synthetic gas using non agglomerating or weak agglomerating coal fluidized destructive distillation

A synthesis gas and cohesive technology, applied in the field of coal chemical industry, can solve the problems of high investment and high operating cost, and achieve the effect of low investment, high raw material utilization rate and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The non-caking or weakly caking coal of the present invention includes: lignite, long-flame coal, and gas coal. The process is used to produce coal tar synthesis gas.

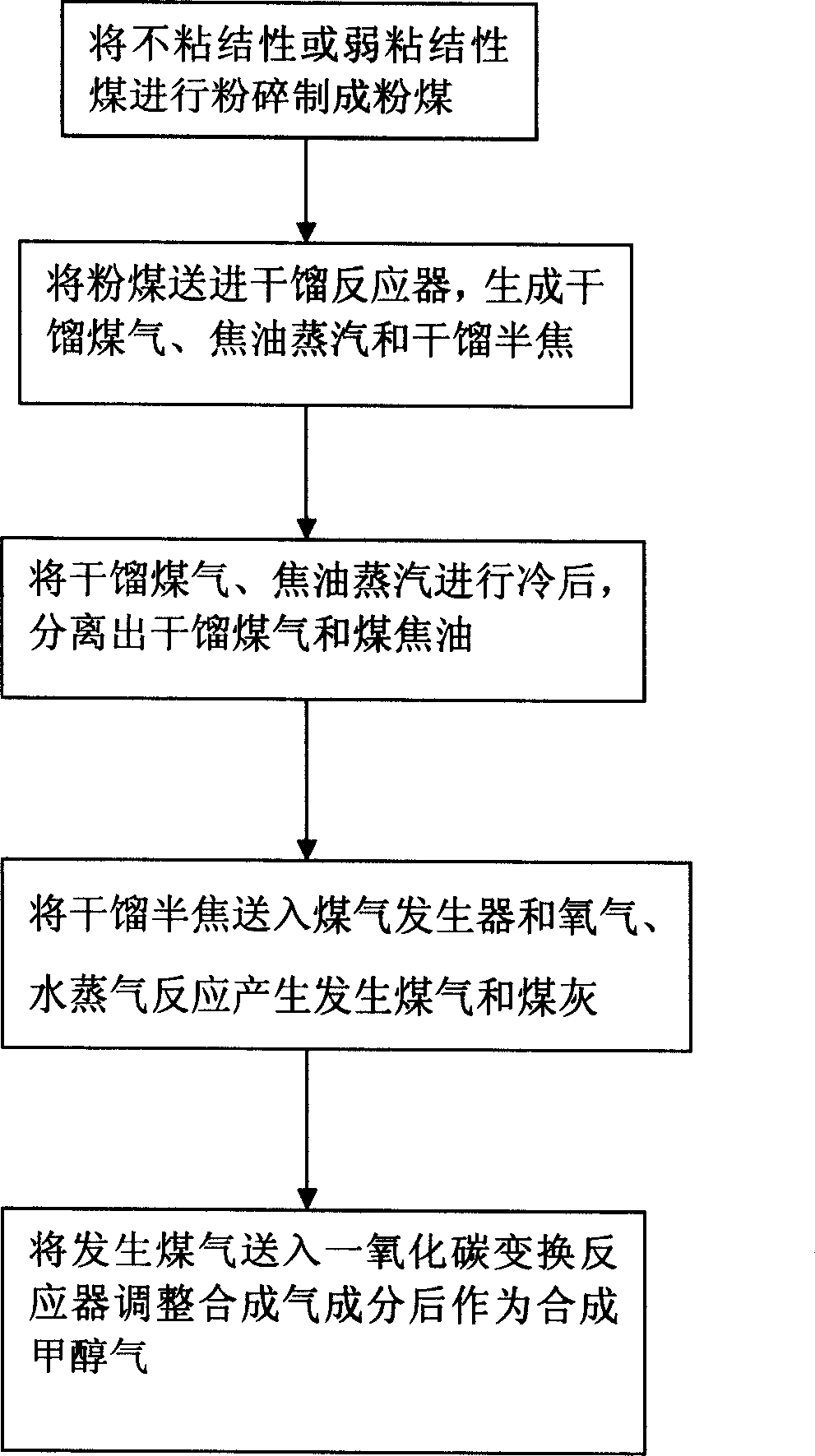

[0030] Refer to attached figure 1 , the present invention a kind of non-caking property or weakly cohesive coal fluidized dry distillation process for producing synthesis gas, comprising the following steps:

[0031] Step 1, pulverizing the non-caking or weakly caking coal from Yunnan Xianfeng Coal Mine to make pulverized coal; the particle size is in the range of 0-1000 microns, showing a normal distribution.

[0032] Step 2, send the obtained pulverized coal into the carbonization reactor for high-temperature heating to generate carbonization gas, tar vapor and carbonization semi-coke; the reaction pressure of the carbonization reactor is 0.1-0.2MPa, the operating temperature is 450-800°C, and the gas-solid ratio is 1.0- 20:1 (v / v), the gas is a mixture of methane, hydrogen, carbon monoxide, carbon di...

Embodiment 2

[0037] The present invention provides a process for preparing synthesis gas by fluidized dry distillation of non-caking or weakly caking coal, comprising the following steps:

[0038]In step 1, the non-caking or weakly caking coal of Harbin Yilan Coal Mine is pulverized to make pulverized coal; the particle size is 20-600 microns, and it is normally distributed. In order to fully heat and facilitate the fluidization reaction.

[0039] Step 2, send the obtained pulverized coal into the carbonization reactor to generate carbonization gas, tar vapor and carbonization semi-coke; the reaction pressure of the carbonization reactor is 0.18MPa, the operating temperature is 600°C, and the gas-solid ratio is 4.5:1 (v / v). A riser reactor is selected as the dry distillation reactor, and a settler is installed on the top of the settler, and a three-stage rotary separation is installed in the settler, so as to minimize the coal ash content in the synthesis gas.

[0040] Step 3, after cooli...

Embodiment 3

[0044] The present invention provides a process for preparing synthesis gas by fluidized dry distillation of non-caking or weakly caking coal, comprising the following steps:

[0045] In step 1, the non-cohesive or weakly cohesive coal of Liangshuijing Coal Mine in northern Shaanxi is pulverized to produce pulverized coal; the particle size is 20-600 microns, and it is normally distributed.

[0046] Step 2, send the obtained pulverized coal into the carbonization reactor to generate carbonization gas, tar vapor and carbonization semi-coke; the reaction pressure of the carbonization reactor is 0.18MPa, the operating temperature is 600°C, and the gas-solid ratio is 4.5:1 (v / v). A riser reactor is selected as the dry distillation reactor, and a settler is installed on the top of the settler, and a three-stage rotary separation is arranged in the settler, so as to minimize the coal ash content in the generated coal gas.

[0047] Step 3, after cooling the dry distillation gas and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com