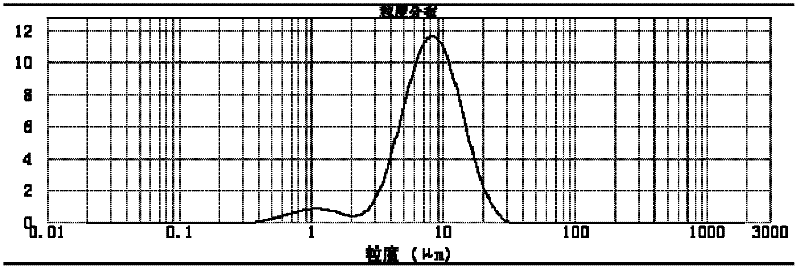

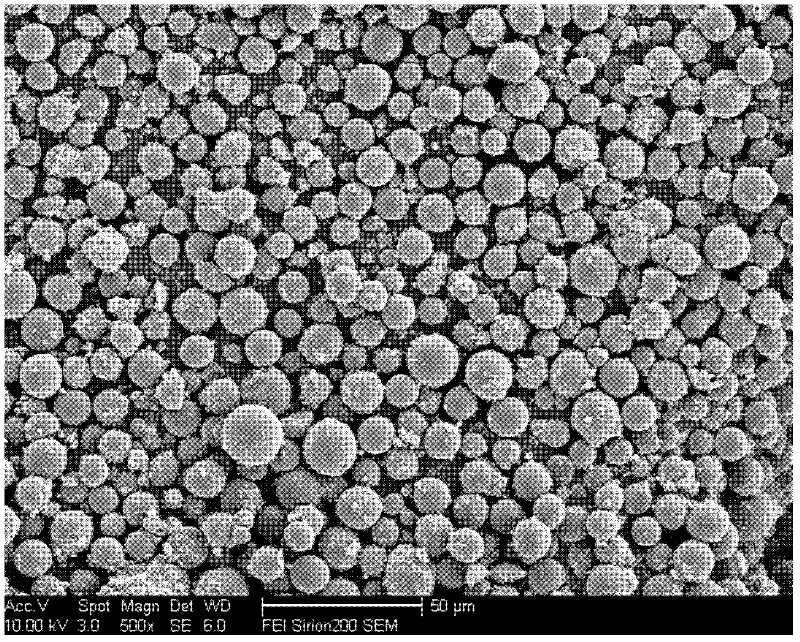

Preparation method of mesophase carbon microspheres from coal liquefaction residues

A technology for mesophase carbon microspheres and coal liquefaction residues is applied in chemical processing of tar pitch/petroleum pitch/natural pitch, tar pitch/petroleum pitch/natural pitch, and petroleum industry, etc. Simple process, smooth ball surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The method for preparing mesophase carbon microspheres from the coal liquefaction residue is completed in the following steps:

[0036] a. Dry the coal liquefaction residue until the moisture content is below 3%, and add one or two of toluene, xylene, and dimethyl sulfoxide to it according to the mass ratio of extraction agent: coal liquefaction residue at a ratio of 1:3 to 4. One or more than two kinds, stirring for 20min for extraction, then centrifuged at 4800-7000r / min to remove insoluble matter, and the extract phase after removal of insoluble matter was evaporated under reduced pressure for 4h at a temperature of 200-220°C and a pressure ≤0.2atm , to obtain refined pitch containing 0.5% quinoline insoluble matter, and its softening point is 92°C;

[0037] b. Add 2% of nucleation accelerator and 0.7% of chemical auxiliary agent to the refined asphalt obtained in step a. Heat to a temperature above the softening point, then stir and mix the chemical additives and n...

Embodiment 2

[0040] The method for preparing mesophase carbon microspheres from the coal liquefaction residue is completed in the following steps:

[0041] a. Dry the coal liquefaction residue until the moisture content is below 3%, and add one or two of N-methylpyrrolidone, quinoline, and pyridine in a mass ratio of extraction agent: coal liquefaction residue of 1:4-5. One or more kinds, stirring for 30-40 minutes to extract, and then separate and remove the insoluble matter at a rotating speed of 4800-7000r / min. The extract phase after removal of insoluble matter was evaporated under reduced pressure for 5 hours at a temperature of 220-240°C and a pressure of ≤0.2 atm to obtain refined pitch containing 0.1% quinoline insoluble matter, and its softening point was 101°C.

[0042] b. Adding 1.3% of chemical additives and 1% of nucleation accelerator by mass of the refined asphalt to the refined asphalt obtained in step a. Heat to a temperature above the softening point, then stir and mix t...

Embodiment 3

[0045] The method for preparing mesophase carbon microspheres from the coal liquefaction residue is completed in the following steps:

[0046] a. Dry the coal liquefaction residue until the moisture content is below 3%, and add one or both of tetrahydrofuran and dimethylacetamide to it according to the mass ratio of extractant: coal liquefaction residue at 1:5-6 (simultaneously The mass ratio of tetrahydrofuran and dimethylacetamide is 4:6 when two kinds are selected), stirred for 30-40 minutes for extraction, and then centrifuged at 4800-7000 r / min to remove insoluble matter. The extract phase after removal of insolubles was evaporated under reduced pressure for 5 hours at a temperature of 230-250°C and a pressure of ≤0.2atm to obtain refined pitch containing 0.1% quinoline insolubles, and its softening point was 92°C.

[0047] b. Adding 1.8% of chemical additives and 1.5% of nucleation accelerator to the refined asphalt obtained in step a. Heating to a temperature above the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com